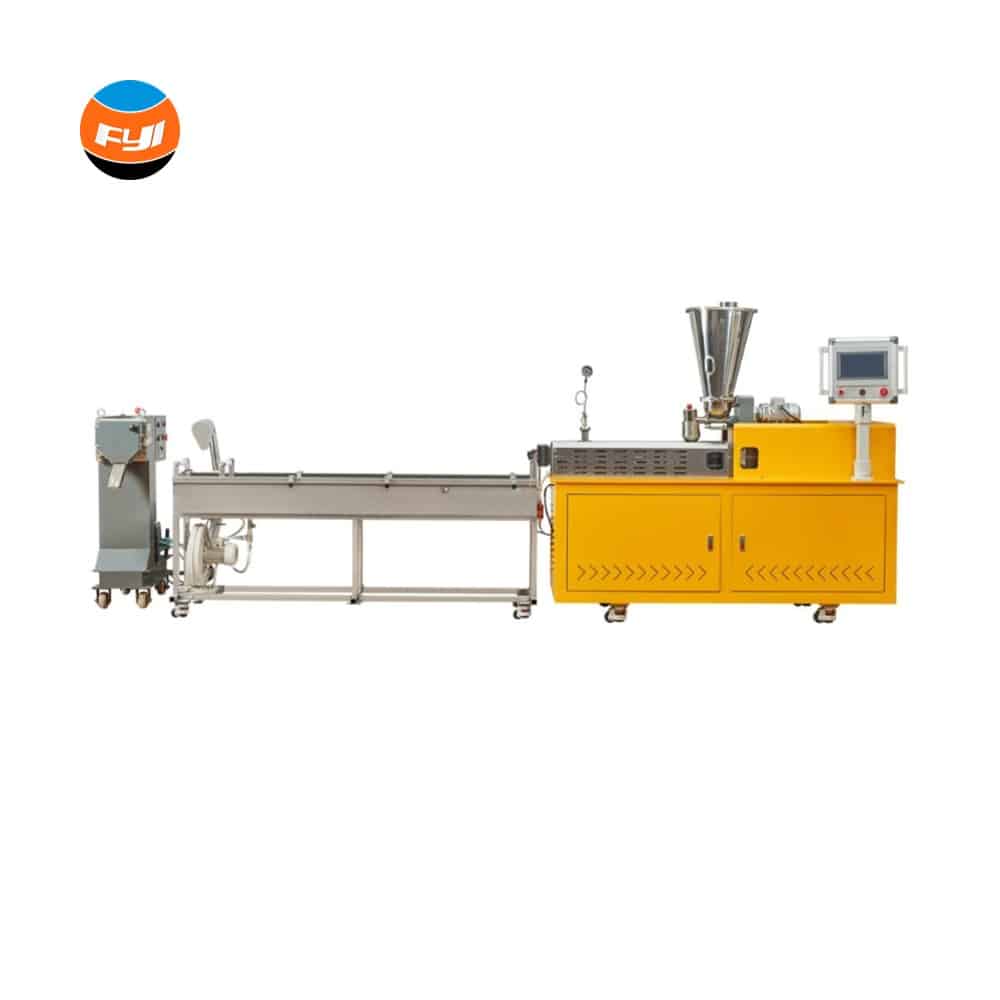

Lab Twin Screw Extruder DW5210B

With its ability to mix, plasticize, and extrude engineering plastics, modified plastics, masterbatch, and other high polymers with uniform dispersion, plastic coloring, and filling to modify, the DW5210B Lab Twin Screw Extruder can be used for quality control, teaching, research, and small-scale production.

Lab Twin Screw Extruder DW5210B

DW5210B Lab Twin Screw Extruder can be applied to the mixing, plasticizing and extrusion of engineering plastics, modified plastics, masterbatch and other high polymers with the features of uniformly dispersed, plastics coloring and filling to modify. It can be used in laboratory tests, quality control, teaching research and small-scale production.

Here are the features of the machine:

- The mandrel of screw is made of 40CrNiMoA chrome-molybdenum alloy tool steel, treated by nitriding, hardening and tempering, chromium plating and super-fine grinding, resistant to corrosion.

- The material selected for the barrel is a nitriding steel integral sleeve, which has undergone nitriding treatment and surface rust prevention treatment. The barrel is water-cooled.

- The deceleration and torque distribution parts of the main transmission box are integrated, adopting a parallel three-axis design with a compact structure. NSK bearings are used for deceleration, torque distribution, and radial bearings on both output shafts.

- Use a melting temperature thermocouple to measure the melting temperature of the material, and use a pressure sensor to measure the material pressure.

- 38CrMoAl chromium molybdenum alloy machine head, with a nitriding hardness of HRC60 and a die strip hole number of 2- Φ 3.0. It adopts a quick connecting snap ring for quick disassembly and assembly of the machine head, making it easy to connect with downstream equipment and saving time and effort in test conversion.

- Fully automatic computer Weilun Tong PLC control mode :with LCD touch screen, all extruder parameters can be viewed from the touch screen, and can be connected with external PC.

Application

Application of Lab Twin Screw Extruder

With its ability to mix, plasticize, and extrude engineering plastics, modified plastics, masterbatch, and other high polymers with uniform dispersion, plastic coloring, and filling to modify, the DW5210B Lab Twin Screw Extruder can be used for quality control, teaching, research, and small-scale production.

Standards

Lab Twin Screw Extruder Extruder Standards

Key specification

Key specification of Lab Twin Screw Extruder

| Control mode | PLC display |

|---|---|

| Output | Approx. 2~15kg/h (depending on the technique formula) |

| Screw diameter | Φ21.7mm |

| Screw L/D | 40 : 1 |

| Screw rotating speed | 60~500rpm |

| Direction of screws | Parallel co-rotating |

| Heating section | Five cast aluminum heating sections for charging barrel |

| Cooling device | Air compressor cooling system, Compressed air cooling is used inside the barrel, which is clean and convenient |

| Drive power | 4 kw |

| Power supply | AC380V, 50Hz, 3 phase |

| Dimensions | 1,950×500×1,500mm (L×W×H) |

| Weight | Approx. 350kg |

You must be logged in to post a review.

Reviews

There are no reviews yet.