Dry Jet Wet Spinning Machine DW7091A

DW7091A Dry Jet Wet Spinning Machine is suitable for preparation of various chemical fiber materials including long and short fibers and BCF filaments. It is widely used in the production of polyacrylonitrile fiber, aromatic polyamide fiber, polybenzimidazole fiber, etc.

Dry Jet Wet Spinning Machine DW7091A

DW7091A Dry Jet Wet Spinning Machine is specially designed for researching new material in the field of textile, macromolecule and other material by a combination of dry and wet methods.

See more details about wet spinning process: Wet Spinning

Here are the features of the spinning machine:

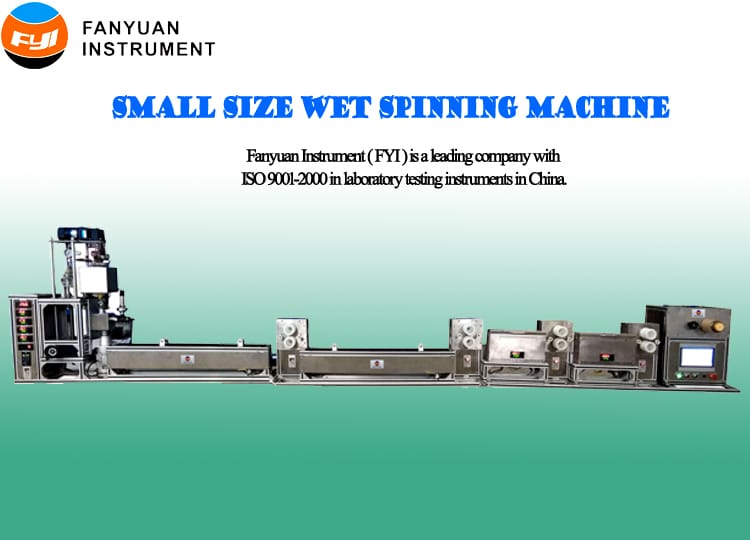

- The spinning machine mainly consists of raw material tank (with heating, stirring), metering pump (with heating), filter, spinneret cap, coagulation bath (with heating), water bath (with heating), drafting roller, heating box (drying/setting) and winding roller;

- Touch screen control and display interface;

- Real-time acquisition and control the temperature of the raw material tank, metering pump, coagulation bath, water bath and heating box;

- Real-time acquisition and display the raw material tank pressure;

- Real-time display the flow of metering pump;

- Roller and metering pump frequency control.

Application

Application of Dry Jet Wet Spinning Machine

A variant of wet spinning is dry jet wet spinning, which is called dry-wet spinning for short. It is a chemical fiber spinning method which combines the characteristics of dry spinning and wet spinning. This is a new spinning method developed in the 1960s.

Dry Jet Wet Spinning machine has been used in the production of polyacrylonitrile fiber, aromatic polyamide fiber, polybenzimidazole fiber, etc.

The spinning speed of dry jet wet spinning can reach 600 ~ 1200 m/min, which is much higher than that of wet spinning. And the spinneret with larger aperture (φ=0.15 ~ 0.3 mm) can be used. However, the concentration and viscosity of the spinning solution can be as high as that of dry spinning. What’s more, the structure formation process of the fiber can be controlled effectively by dry jet wet spinning. In dry spinning, the solidification speed of liquid flow is often very slow due to the limit of solvent evaporation speed. In dry-wet spinning, the flow of liquid (fiber) being drawn enters the coagulating bath. And the solidification rate and fiber structure can be changed over a wide range by adjusting the composition and temperature of the coagulating bath.

Standards

Dry Jet Wet Spinning Machine Standards

Key specification

Key specification of Dry Jet Wet Spinning Machine

| Control mode | PLC & touch screen |

|---|---|

| Raw material tank | Volume: 1L With stirring function With nitrogen interface Having a feeding opening with a glass window Temperature range: 0~80℃ |

| Metering pump | Frequency control, flow: 0.6cc/rev Temperature range: 0~80℃ |

| Filter | Material: stainless steel |

| Spinneret cap | Material: tantalum, external diameter: φ16mm |

| Coagulation bath | Material: stainless steel Dimensions: 1000*160*160 mm Temperature range: 0~80℃ With cover |

| Water bath | Material: stainless steel Dimensions: 1000*160*160 mm Temperature range: 0~80℃ |

| Drafting roller | Size: φ50×80mm, linear speed: 0~20m/min, adjustable |

| Heating box | Temperature range: 0~200℃ |

| Winding roller | Main body material: stainless steel Linear speed: 10~40m/min, adjustable Tube material: paper tube |

| Power supply | AC 220V, 50Hz or 380V, 50Hz, three-phase |

1 review for Dry Jet Wet Spinning Machine DW7091A

You must be logged in to post a review.

Mohan Mehrotra –

When it comes to quality, this wet spinning machine really stands out. It’s clear that a lot of care and attention went into its production.