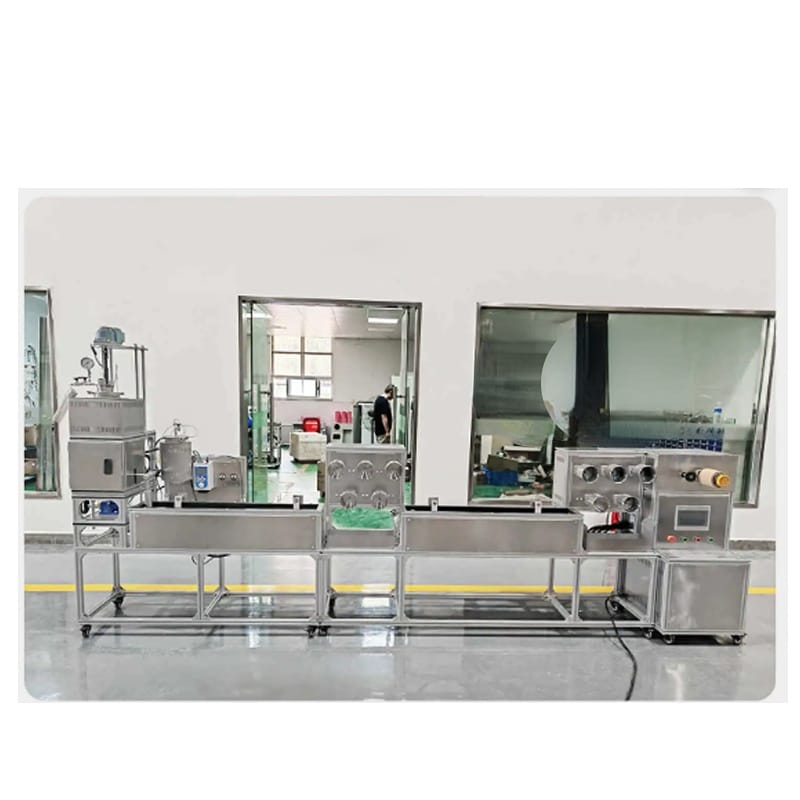

Wet Spinning Machine DW7091A for Hollow Fiber

The DW7091A wet spinning machine is ideal for creating metal hollow fibers and core-skin composite fibers; it has a spinning mechanism for producing spandex and a heating furnace with a layered cover design and 1.5 kW of heating capacity. The system has a spinning gear for producing spandex, a 1.5 kW heating power, and a layered cover design for the heating furnace.

Wet Spinning Machine DW7091A for Hollow Fiber

DW7091A wet spinning machine is specially designed for researching alginate in the field of textile, macromolecule and other material by a combination of dry and wet methods.

- The spinning machine mainly consists of raw material tank (with heating, stirring), metering pump (heating), filter screen, spinneret cap, coagulation bath (with heating), water bath (with heating), drafting roller, heating box (drying/setting) and winding roller;

- Touch screen control and display interface;

- Real-time acquisition and control the temperature of the raw material tank, metering pump, coagulation bath, water bath and heating box;

- Real-time acquisition and display the raw material tank pressure;

- Real-time display the flow of metering pump;

- Roller and metering pump frequency control.

Application

Application of Small Size Wet Spinning Machine

Wet spinning is the oldest of the five processes. The polymer is dissolved in a spinning solvent where it is extruded out through a spinneret submerged in a coagulation bath composed of nonsolvents. The coagulation bath causes the polymer to precipitate in fiber form.

Wet Spinning machine can be used in the teaching and research experiments of new fiber manufacturing, functional fiber development and raw material spinnability. Here are the features of this machine:

- The spinning machine mainly consists of raw material tank (with heating, stirring), metering pump (heating), filter screen, spinneret cap, coagulation bath (with heating), water bath (with heating), drafting roller, heating box (drying/setting) and winding roller;

- Touch screen control and display interface;

- Real-time acquisition and control the temperature of the raw material tank, metering pump, coagulation bath, water bath and heating box;

- Real-time acquisition and display the raw material tank pressure;

- Real-time display the flow of metering pump;

- Roller and metering pump frequency control.

Standards

Wet Spinning Machine Standards

Key specification

Key specification of Wet Spinning Machine

| Spinning kettle | 1. Tank material: 316L 2. Tank volume: 2 L 3. Interface configuration: upper feed, bottom |

|---|---|

| Core liquid system |

|

| Bottom filter |

|

| Pump front end connection pipe |

|

| Measurement system | 1. Metering pump flow: 3cc/rpm 2. Transmission mode: cycloidal reducer motor 3. Motor power: 370W 4. Reduction ratio of reducer: 1:59 |

| Pump back end connection tube | 1. Material: 316L stainless steel 2. Use: metering pump output end to candle filter |

| Candle filter | 1. Material: 316L stainless steel 2. Filtration accuracy: 6.5-13um |

| Gooseneck | 1. Material: 316L stainless steel 2. Size: Outer diameter 12mm inner diameter 6mm |

| Spinneret | 1. Material: 316L stainless steel 2. Composition: gooseneck connecting seat, pressing cap, sealing gasket, spinning tube |

| Coagulation bath/water bath | 1. Material: 316L stainless steel 2. Dimensions: 1000x160x160 3. Inlet and outlet diameter DN15 4. With two sets of press roller, temperature sensor port |

| Hot water circulation system | 1. Material: 316L stainless steel 2. Structure: closed hot water tank; 3. Temperature control range: RT-90℃, accuracy: ±0.5℃ 4. Circulation mode: high temperature and corrosion resistant circulation pump |

| Intermediate winding/drawing roll | 1. Active speed regulating winding roller 2. With in and out of the deviation correction driven wheel 3. Frequency control motor |

| Rewinding | 1. Open the paper tube quickly 2. Common cabling device 3. Frequency conversion deceleration speed regulation 4. Winding speed: ≤40m/min |

| Touch screen control | 1. Control mode: PLC+ touch screen + software 2.. Integrated centralized control box, 3.. Centralized touch interface: temperature control/temperature measurement/flow/pressure/speed 4. Data can be saved and remote transmitted 5 .380V power supply |

| Bottom frame of bench | 1. Material: 30×30 aluminum alloy frame 2. Overall design, section connection |

You must be logged in to post a review.

Reviews

There are no reviews yet.