Wet Spinning Machine DW7091A for Alginate Fiber

DW7091A Wet Spinning Machine for Alginate Fiber is suitable for preparation of various chemical fiber materials including long and short fibers and BCF filaments.

Wet Spinning Machine DW7091A for Alginate Fiber

Alginate fiber is prepared by wet spinning. Wet spinning is to dissolve the fiber polymer in the appropriate solvent to get the spinning spinning solution. The spinning solution extruded through the spinneret and then enters the coagulation bath and precipitates out in the coagulation bath to form the fiber.

- Dissolution: weigh a certain amount of sodium alginate powder and slowly add it to a certain amount of deionized water while stirring. Under the heating condition of 50℃, get the sodium alginate solution with 4% mass percentage.

- De-foaming: In the laboratory, vacuum de-foaming method usually be used, the vacuum degree is controlled at 0.07-0.08Mpa, and the temperature is kept at 50℃. After de-foaming, spinning stock solution can be obtained.

- Introduce the spinning solution into the materials tank, the temperature is maintained at 50℃, and the pressure is not higher than 0.3Mpa through compressed air.

Application

Application of Small Size Wet Spinning Machine

Wet spinning is the oldest of the five processes. The polymer is dissolved in a spinning solvent where it is extruded out through a spinneret submerged in a coagulation bath composed of nonsolvents. The coagulation bath causes the polymer to precipitate in fiber form.

Wet Spinning machine can be used in the teaching and research experiments of new fiber manufacturing, functional fiber development and raw material spinnability. Here are the features of this machine:

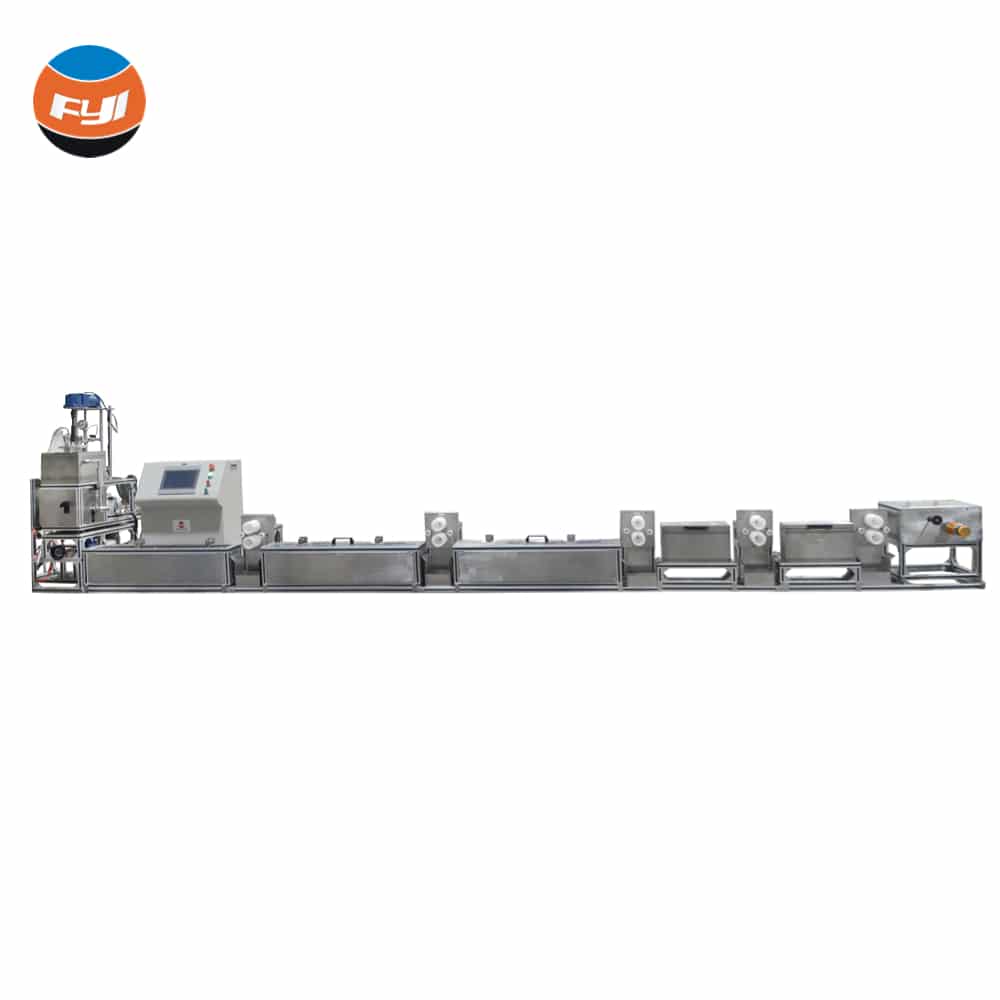

- The spinning machine mainly consists of raw material tank (with heating, stirring), metering pump (heating), filter screen, spinneret cap, coagulation bath (with heating), water bath (with heating), drafting roller, heating box (drying/setting) and winding roller;

- Touch screen control and display interface;

- Real-time acquisition and control the temperature of the raw material tank, metering pump, coagulation bath, water bath and heating box;

- Real-time acquisition and display the raw material tank pressure;

- Real-time display the flow of metering pump;

- Roller and metering pump frequency control.

Standards

Wet Spinning Machine Standards

Key specification

Key specification of Wet Spinning Machine

| Control mode | PLC & touch screen |

|---|---|

| Raw material tank |

|

| Metering pump |

|

| Filter screen | Material: stainless steel |

| Spinneret cap | Material: tantalum, external diameter: φ16mm |

| Coagulation bath |

|

| Water bath |

|

| Spinneret plate | 100 holes, hole dia.: 0.07mm Material: tantalum |

| Drafting roller | Size: φ50×80mm, linear speed: 0~20m/min, adjustable |

| Heating box | Temperature range: 0~200℃ |

| Winding roller |

|

| Power supply | AC 220V, 50Hz or 380V, 50Hz, three-phase |

1 review for Wet Spinning Machine DW7091A for Alginate Fiber

You must be logged in to post a review.

Clement DeQuincey –

Excellent Seller I recommend buying it from a very helpful friend