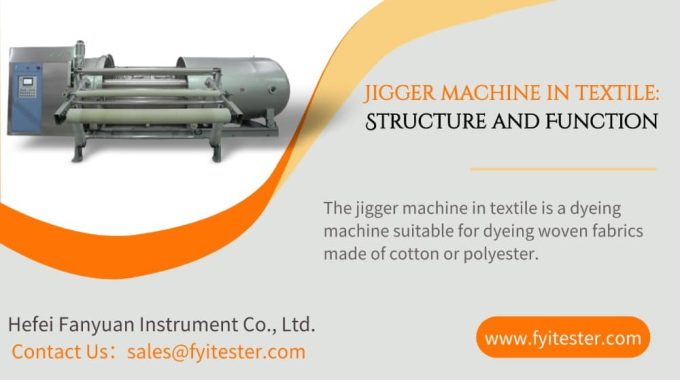

Jigger machine in textile: Structure and Function

The jigger machine in textile is a dyeing machine suitable for dyeing woven fabrics made of cotton or polyester. In the jigger dyeing process, the cloth-collecting roller is used as the driving force. The fabric to be dyed is unwound from the cloth-releasing roller, colored in the dye liquid in the dye trough by the cloth-guiding roller, and then rolled up on the cloth-collecting roller. After the fabric on the cloth-releasing roller has finished running, it is rolled back. This reciprocating operation achieves the purpose of dyeing. In this article, I will introduce the functions and advantages of each structure of our company’s high temperature jigger dyeing machine.

Contents

Bottom frame

The bottom frame is located under the vessel, equipped with a motor and a slide rail to facilitate automatic opening and closing of the vessel. The whole is made of USU201 stainless steel, which is strong and durable.

Vessel

The vessel is the part of the jigger outside the main roller and the liquor vat. When dyeing starts, the vessel will be closed. At this time, the interior is in a sealed state and can be pressurized to reach the required temperature. The following are the advantages of the vessel:

- It is made of SUS304 stainless steel for dyeing temperatures up to 135℃ and rated pressure up to 0.3MPa;

- Vessel is open and close by electro-motor, the open state is supervised with travel switch;

- Locking system is working through pneumatic system, internally equipped with high-temperature resistant sealing rings to ensure the sealing property of the vessel.

Liquor vat

The liquor vat is a container for storing dye in the jigger dyeing machine, and a maximum of 160 kg of dye can be added. Since some dyes are corrosive, the liquor vat is made of SUS316L stainless steel, which greatly increases the service life of the liquor vat. At the same time, in order to monitor the temperature and proportion of the dye in real time, the liquor vat is equipped with a temperature sensor and a liquid level meter for easy observation by users. In addition, direct heating and indirect heating pipelines are installed at the bottom of the liquor vat for rapid heating of the dye.

Main Rollers

The jigger machine typically consists of two main rollers that are mounted on smooth bearings. These rollers are crucial as they facilitate the movement of the fabric through the dyeing process. The fabric is transferred from one roller to another, allowing it to pass through the dye bath repeatedly. This method ensures even dye penetration across the fabric.

The main rollers are covered by 2mm SUS316L stainless steel, which has strong anti-corrosion performance. Two main rollers are both driven by frequency-conversion controlled motors, achieving constant fabric speed and tension control.

Expander frame

The expander frame is located under the main roller and is used to control the tension to ensure that the fabric can be dyed evenly during the dyeing process. Since it also needs to be in contact with the dye solution, it is made of SUS316L stainless steel like the liquor vat and the main roller. Equipped with guide roller,ensuring fabrics crease-free during the dyeing process.

Control System

Modern jigger machines may include electronic control systems to regulate the speed of the rollers, manage the dyeing time, and monitor the temperature of the dye bath, further improving the dyeing accuracy and efficiency.

- Electrical cabinets are made of SUS304 stainless steel, can resist to corrosion and harsh environment;

- Adopt 10 inches touch screen, easy to learn and operate. User can edit, save or calling the program according to process requirements;

- Auto and manual mode are available. The manual mode allows main roller speed acceleration and deceleration operation for process trial;

- Automatically keep fabric speed and tension constant and control liquor level and temperature;

- Auto passages recording and reversing, auto stopping and swinging fabric between two main rollers.

Circulation system

The circulation system includes a circulation pump, a circulation pipe line, a filter, and a set of valves; it ensures the evenness of temperature and the chemicals/dye stuffs distribution. 2.2 KW powerful circulation pump, ensures well liquor circulation and prevents dead zones in the vat. Equipped filter device in the circulation pipeline to avoid pipe blockage by waste fibers.

Heat exchanger (Optional configuration)

A high-capacity heat exchanger integrated in the circulation system allows fast and efficient heating and cooling.

Additional tank

Additional tank integrates the functions of re-flow, dosing, heating, mixing, water intake, and discharge and can automatically complete the feeding operation according to the dyeing process. Additional tank connected to the circulation system through pipelines can automatically complete the dosing step according to the dyeing process. Equipped with a mixing motor, which can fully stir and mix the dye liquor.

Debatching device

Debatching arm lifting adopts pneumatic control, which is easy to operate. A rubber roller is controlled by an individual motor, and its speed can be adjusted. Equipped with an expander-roller to ensure fabrics are crease-free during transmitting.

Conclusion

This is about the functions and advantages of the JRHP series high temperature dye jigger structure. In addition, our company also has laboratory normal temperature jigger dyeing machine designed specifically for testing dye formulas before mass production, as well as normal temperature dye jiggers with similar structures to the high temperature jigger dyeing machine in this article for sale. If you want to know more about jigger machine in textile, please contact us as soon as possible.

Here are other articles about jigger dyeing machine you might be interested in:

Unlocking the Secrets of Jigger Dyeing: A Comprehensive Guide to Our Advanced Machines