Garment Dyeing Process and Application

Contents

Introduction

In the modern society with the rapid development of science and technology, people have higher requirements for food, clothing, housing, use and transportation. Especially under the premise of the diversification of social forms and the general improvement of people’s living standards, people’s requirements for clothing wear function are getting lower and lower, and the requirements for clothing are also increasingly emphasizing its style, color and other personalized requirements. Therefore, the garment dyeing and finishing art has developed rapidly.People need to have diverse designs and requirements for clothing. At the same time, the development trend of fashion clothing style, fabric novelty, color diversity, personalized and traditional industrial production, large quantities of supply and demand contradiction is more prominent, small batch, multiple varieties, short process of clothing production can follow the trend of clothing fashion color development, which also promotes the development of clothing dyeing.

Therefore, the dyeing and finishing process is needed to make the garments have their own characteristics. Through the garment dyeing and finishing technology, further meet people’s design requirements.

Along with the dyeing and finishing process and its equipment has also developed a great change. Dyeing and finishing as a relatively new technology can show the unique features of different types of clothing, which is conducive to providing consumers with personalized, novel and tasteful clothing products. At the same time, it is also conducive to improving the comfort of clothing wearing, greatly improving the functionality of ready-made clothing. There are great differences in dyeing and finishing technology of various kinds of clothes.

Characteristics of garment dyeing and finishing process

Garment dyeing and finishing is mainly through the treatment of untreated fabrics and processed fabrics, after expanding the proportion size, sewing clothes according to the shrinkage rate of clothes and fabrics, and dyeing and finishing of garments, providing processing and dyeing and finishing of garments.

In the process of garment dyeing and finishing, special processing methods are needed to be processed, and dyeing and finishing equipment is used to improve the efficiency of production. Generally speaking, the dyeing process of garments is mainly processed by loose equipment. Various treatments, dyeing and finishing are carried out in the washing machine, and the garments are dried by hot air.The products processed by dyeing and finishing technology have softness, fluffiness, wrinkle-resistance and drape better than before dyeing and finishing. After dyeing and finishing the garment, the fiber on the surface of the garment is more fluffy, the feel is smooth, and the surface finish is higher. And after the special dyeing and finishing process of clothing also has other characteristics.

Garment dyeing

Different fibers have different properties. Because of the different structure of each fiber, it is necessary to adopt different process in dyeing and finishing process, especially for garment dyeing, so as to achieve the best dyeing and finishing effect. In order to make the clothing style fashion, fabric novelty, color diversity, personalized, promote the development of garment dyeing.

Cellulose fibre dyeing

Dye selection: We know that cellulose fiber is easy to dye, and a variety of dyes can be used, such as reactive dyes, direct dyes, vulcanized dyes and so on. We should choose appropriate dyes for coloring according to the dyeing and finishing effect of garments.

Dyeing process: Take reactive dyes as an example, in the dyeing and finishing process of cellulose fiber, it needs to go through three steps, such as dyeing, color fixing and treatment, to improve the dyeing firmness. Since reactive dyes are easily dissolved in water, appropriate salt can be added during the dyeing process to promote the absorption of dyes by cellulose fibers.

If you choose reductive dyes, you need to go through the reduction of dissolved, hidden chromophore dyeing, hidden chromophore oxidation, soap cooking and other stages. Since reductive dyes are insoluble in water, they must be dyed in an alkaline solution.

Vulcanized dyes are aromatic and phenolic compounds containing sulfur and polysulfide in dyes. The cost of vulcanized dye is relatively low, and it is widely used in the dyeing process of cotton fabric and cellulose fiber, but it is not resistant to chlorine bleaching, and it is easy to fade after sun exposure. So vulcanized dyes are generally used in the dyeing of dark clothing.

Direct dyes belong to azo and heterocyclic dyes. It can be divided into several types according to the performance used. In the process of garment dyeing and finishing, the common ones are: direct fast dye, direct copper salt dye, direct crosslinking dye, direct blend dye and so on.

Dyeing of silk garments

It is relatively easy to color real silk garments, because silk fabrics generally have good dyeing performance and can be treated with acidic, reactive, alkaline and other dyes. From the aspects of brightness, color rate, saturation and so on, acid dyes and reactive dyes are mainly used.

It is very simple to color mulberry silk fabric with acid dye. You just need to fix the color. Acid dyes can be divided into strong acid type, weak acid type, neutral bath dyeing acid dyes. Strong acid dyes are commonly used in dyeing wool fabrics. Weak acids are used in dyeing silk and nylon fibers. Acid dyes for neutral bath dyeing are also dyes for dyeing silk fabrics.

Dyeing of silk garments with reactive dyes. In the process of dyeing, because mulberry silk is easy to color, so silk garments can choose a variety of dyes for dyeing and finishing treatment. Generally speaking, the color of the weak acid dye is more bright, but the degree of fixation is not high. Neutral dyes have a good degree of color fixation, but the color is not high. Reactive dyes are bright in color, such as red, yellow and other bright colors, and easy to fix.

Dyeing wool garments

Sweater dyeing dye also has a variety of, such as: acid dye, acid medium dye, wool special reactive dye and so on. These dyes have their own advantages, relatively bright color, more complete chromatography. Because of the poor fixation ability of acid dyes, acid medium dyes and acid coal dyes are widely used in sweater dyeing.

The elements of wool fiber are mainly composed of carbon, hydrogen and nitrogen, and the main component is protein. Therefore, it is necessary to pay attention to the selection of appropriate dyes according to the specifications and dyeing requirements of woolen sweaters in the dyeing process, so that woolen sweaters can be dyed evenly, reduce the damage to wool and ensure the color of woolen sweaters.

Dyeing wool blended garments

Wool-blended garments mainly refer to garments made of two or more kinds of textile materials. In the blend, if it contains wool fiber, it is a wool blend, if there is no wool fiber, it is a wool-like blend.

Dyeing wool and nitrile blended fabric

Wool and nitrile blended fabric dyeing, light color can be used in one bath method, dark color using one bath two steps or two bath method. One – bath dyeing mainly refers to the use of cationic dyes, weak acid dyes and neutral dyes for dyeing. Two-bath dyeing method can be used to dye wool nitrile textiles. Weak acid dyes and neutral dyes or acid medium dyes are used to dye wool, and then a new bath is used to dye acrylic textile garments with cationic dyes.

Dyeing of wool/cellulose fibre blends

There are two types of wool/viscose blends, woolen and fine. The two kinds of products should be dyed according to different dyeing and finishing requirements. Generally speaking, one – bath or two – bath dyeing is used for wool – viscose blended fabrics. Similar to the wool and nitrile blended fabric, the blended fabric of the same color can be dyed by direct dye with one bath method; For the woolen products with high wool content, for the products with higher dyeing requirements, the two-bath method should be used for dyeing.In the use of two-bath method to use the acid dye, acid medium dye and so on shrinkable wool fabric, wool cleaning. Direct dye is used to dye the viscose fibers. Before dyeing with the direct dye, it is necessary to clean up the residual acid and the pH value of the dye solution, to avoid dyeing wool in the acid bath with the direct dye, so that the color is not gorgeous.

Wool/brocade blended fabric dyeing

Wool/brocade blends are usually dyed in one bath. Since both wool and nylon can be dyed with acid dyes, the main difference between them is that the color saturation value of nylon is low and the dyeing rate is high. The color saturation value of wool is high, but the dyeing rate is low. Therefore, when dyeing wool/brocade blended fabric, the amount of dye should be controlled. When dyeing medium and light colors of wool/brocade blended fabrics, surfactants or non-ionic surfactants should be used in moderation to slow dyeing.

Dyeing of acrylic and blended garments

Acrylic fiber, also known as artificial wool, also has strong heat retention and is soft and moth-free. It has good dyeing ability and can be made into all kinds of clothing. Acrylic blended fabrics are mainly pure acrylic sweater, wool/acrylic sweater, acrylic/rabbit sweater.

Dyeing pretreatment

Dyeing acrylic sweater and imitation cashmere sweater

For pure acrylic sweater and imitation cashmere sweater, dyeing pretreatment is mainly refining, removing oil and impurities on acrylic fiber and other short fibers. Because the acrylic fiber has a certain whiteness, better bleaching effect can be achieved by fluorescence whitening.

According to the characteristics of acrylic fiber, cationic dyes can improve the dyeing fastness and color. In the process of dyeing, first use acetic acid to adjust the pulp, then rinse with boiling water, continue to heat up to 70°, add additives and dissolved cationic dye, dye for 2min, fully dye, put the imitation cashmere sweater, dyeing according to the heating process. After the end of dyeing, cool down with cold water, wait for 40min, cool down to 55℃, drain the residual liquid, rinse again, add softener and soak for 20min, dry, ironing and shaping.

Dyeing polyester and blended garments

Polyester is characterized by strength, elasticity, abrasion resistance, light resistance and corrosion resistance. Therefore, polyester can be made into some special uses of clothing and clothing. However, polyester fiber has poor dyeing performance and can only be stained with disperse dyes.

Disperse dyes can be divided into azo, heterocyclic, temporary soluble decomposition materials, polymerizable polymer disperse dyes and solvent disperse dyes according to their structure. According to the application of the dye, it can be divided into S-type with good fastness to sublimation and poor levelness, E-type with poor fastness to sublimation and good levelness, and SE type in between.

Dispersive dyes, as a kind of non-ionic dyes, have low water solubility and can be diffused into the gaps of polyester fibers. The solubility can be improved by adding an appropriate amount of dispersant. Therefore, the temperature increase of dyeing bath can improve the speed of dyeing, low temperature is not conducive to diffusion.

There are three main dyeing methods for polyester and its blended garments: high temperature and pressure dyeing, hot melt dyeing and carrier dyeing. These three dyeing methods have different requirements for the dye.The most widely used method is carrier staining. Carrier dyeing method does not need high temperature treatment, and can be finished within 100℃ under atmospheric pressure. It can also be manually dyed by using dye VAT. In this way, garments are not too wrinkle-free but very smooth, and the color can be corrected at any time, which is conducive to production.

Taking polyester elastic sweater as an example, polyester low-elastic yarn has good scalability and fluffiness, which makes garments crisp, non-out of shape, non-shrinking, fast drying and soft. It is a common material for sports clothes, coats and tights.

Dyeing of nylon and ammonia cotton garments

Polyamide fiber is hydrophobic fiber and has the best dyeing performance among synthetic fibers. Therefore, polyamide can be dyed with acid dyes as well as disperse dyes. Acid dyes can be combined with amino groups in polyamide fibers to stain polyamide fibers. And the acid dye color bright, more complete chromatography, therefore, has a better evenness.

Garment artistic dyeing

At present, a variety of printed patterns, graffiti patterns of clothing can be seen everywhere. Compared with the traditional dyeing and finishing process, these hand-dyed, batik and color splashed clothes are more suitable for young people to wear, in line with the diversified society for the personalized development of clothing, and is also a new field of clothing dyeing and finishing process development. At the same time, the development trend of fashion clothing style, fabric novelty, color diversity, personalized and traditional industrial production, large quantities of supply and demand contradiction is more prominent, small batch, multiple varieties, short process of clothing production can follow the trend of clothing fashion color development, which also promotes the development of clothing dyeing.

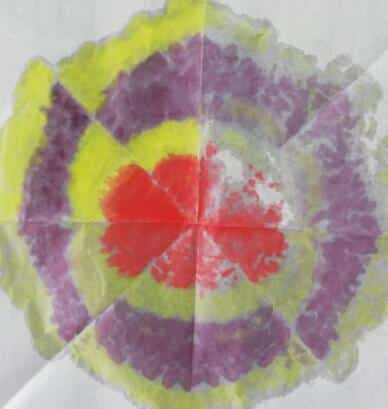

Tie dye

Tie-dye, as the name suggests, is to bind garments and then dye them. Due to the different pressure on garments, different parts of the dyeing degree is different. Therefore, there are different effects of the color halo, the pattern is varied.

Dip dye

The dip dye is a kind of garment dyeing method that makes garments appear gradual, from deep to light, gradual and harmonious. Hanging dyeing has a simple and elegant visual effect. In recent years, it has been widely used in international fashion design. By hanging dye, the costume can be presented with a soft gradual effect. It is widely used in silk, cotton and other high-grade fabrics.

Batik

Batik is to use wax as an anti-dyeing agent, which is coated and brushed on the fabric under the condition of heating and melting. After crack treatment, low temperature dyeing was carried out. This allows the fuel to crack into the fiber, creating an artistic effect. Batik is also a traditional manual printing method of Yun-expensive minority nationalities in China. In this way, it is possible to make their headscarves, clothes, skirts, leggings, etc.

Hand painting

It refers to the use of dyes and paints on fabric or clothing. Hand painting is free and less restricted by craft. It has the advantages of irreplaceable machine printing, a variety of painting methods, rich color, can better reflect the personalized requirements of clothing fabric.

Advantages of garment dyeing

Garment dyeing is an intermittent processing. The pre-treatment, dyeing and post-finishing of garments are carried out in the garment dyeing machine. In the dyeing and finishing process of garments, special processing methods are needed to be processed, and dyeing and finishing equipment is adopted to improve the production efficiency. Its processing time is long, in the production, the process conditions will be due to some uncertain factors and random changes, resulting in uneven dyeing, serious cylinder difference and other phenomena.

- Reactive dyes have little dependence on dyeing process conditions, good dyeing stability and good reproducibility. In the dyeing and finishing process of garments, special processing methods should be adopted to process and dyeing and finishing equipment should be adopted to improve the production efficiency. It is flexible to the dyeing process conditions, and can greatly reduce the color difference and cylinder difference caused by the constant random change of the dyeing process conditions, so as to reduce the repair rate and the rate of defective dyeing products, improve the labor efficiency, and have obvious economic benefits.

- Reactive dyes have high dyeing rate and color fixation rate, full color, bright color, good compatibility, high enhancement rate and good dyeing depth. It can meet the requirements of the current garment industry, adapt to the needs of diverse color, small batch and many varieties, and greatly improve the grade of garment dyeing.In the process of garment dyeing and finishing, special processing methods are needed to be processed, and dyeing and finishing equipment is used to improve the efficiency of production. It increases the reaction probability of dye and fiber, and the fixation rate is about 80%, which is significantly improved compared with the fixation rate of single active group reactive dye. After dyeing, the dye concentration remaining in the dyeing bath is lower, the dye dosage is less. And the treatment cost of colored sewage is reduced, and the comprehensive economic benefits are significantly improved.

- Reactive dyes are both acid and alkali resistant in chemical structure, oxygen bleaching and chlorine bleaching under general conditions, and also solve the fastness problem of fading due to broken chains in the process of using reactive dyes. It has good dyeing stability and good dyeing fastness. At the same time, but also in line with the clothing style fashion, fabric novelty, color diversification, personalized development trend.

Comments are closed.

Very excellent and informative content. I was hunting for this type of material and thoroughly loved reading it.

Thank you for such an excellent post and review; I am really delighted!

I wish more authors of this calibre would take the effort you spent to research and produce so eloquently.