Main roller traverse structure of jigger dyeing machine

The jigger dyeing machine is a device used for textile dyeing. It has a high degree of automation, is environmentally friendly and energy-saving. It can achieve small batch and multi-variety dyeing and is widely used in the textile dyeing industry.

The fabric is rolled up on a main roller and dyed using dye liquor in a cycle. The fabric is unwound from one main roller A, rolled up on another main roller B. Then unwound from the main roller B and rolled up on the main roller A. During the alternating winding process, the dye liquor continuously passes under the main winding roller. The fabric surface absorbs the dye liquor and then adsorbs, combines and fixes it during the winding process.

Contents

Function of main roller traverse of jigger dyeing machine

The traverse of the main roller of the jigger dyeing machine is a very practical function, which can effectively reduce the color difference between the edges and the center of some fabrics.

Some fabrics are twisted during the weaving process, and the edges are thicker than the middle of the fabric. During the dyeing process on the jigger dyeing machine, it is necessary to stagger the edges of the fabric. Otherwise, when winding, the thickness of the fabric at the edge will be much thicker than in the middle. This will make the tension at the edge and the middle of the fabric different, and it will be more likely that the color of the edge and the middle will be different. Some fabric widths may be skewed to a certain extent, and the traverse of the main roller can help correct the fabric during the dyeing process and improve the fabric width.

The structure of the main roller traverse

The following introduces two common traverse structures of the main roller of the dyeing machine:

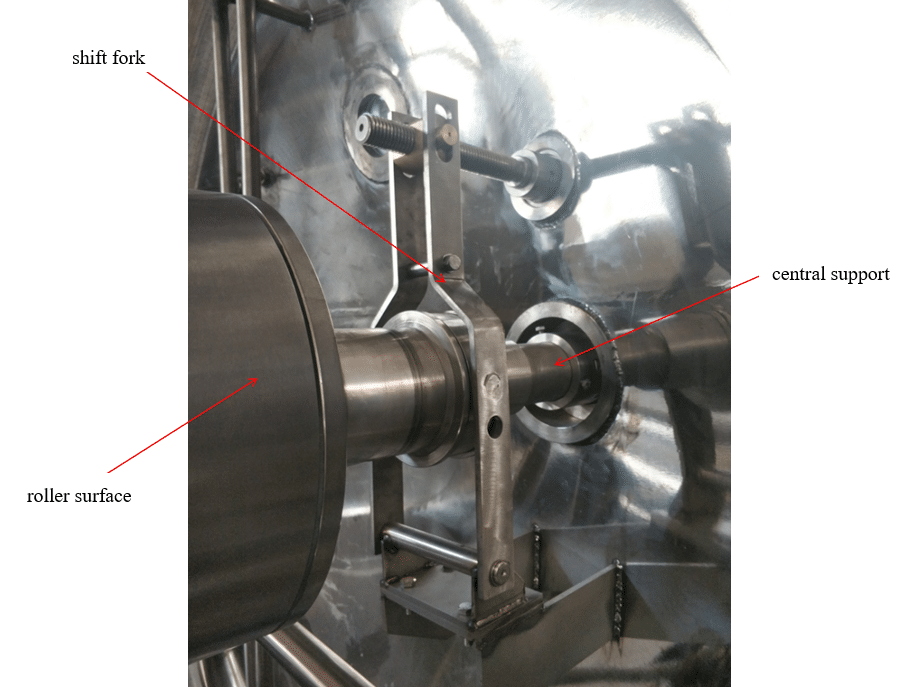

Roller surface moving type traverse structure

(1) Structural features

- The central support of the main roller is fixed.

- The roller surface can move forward and backward along the axis of the central support, and the stroke can generally reach 100mm.

(2) Working Principle

- The power for the roller surface to move is provided by the motor outside the machine driving the screw and shift fork device.

- The lever principle is used to push the roller surface to move along the axis of the center bracket.

(3) Advantages and disadvantages

- Advantages:

- The central support does not move, and the sealing problem between the main roller and the cylinder is relatively easy to solve;

- The forward and reverse rotation can be adjusted by the motor to control the traverse stroke of the main roller.

- Disadvantages:

- The sealing of the connection between the roller surface and the central support needs to be treated with emphasis to prevent the dye from corroding the main roller;

- the dye on the gap between the roller surface and the central support is difficult to clean, which may affect the dyeing of the next batch;

- The strength of the shift fork device will gradually decrease during repeated pushing and pulling, and regular maintenance is required.

(4) Applicable scenarios

- Usually used in high temperature and high pressure jigger dyeing machines.

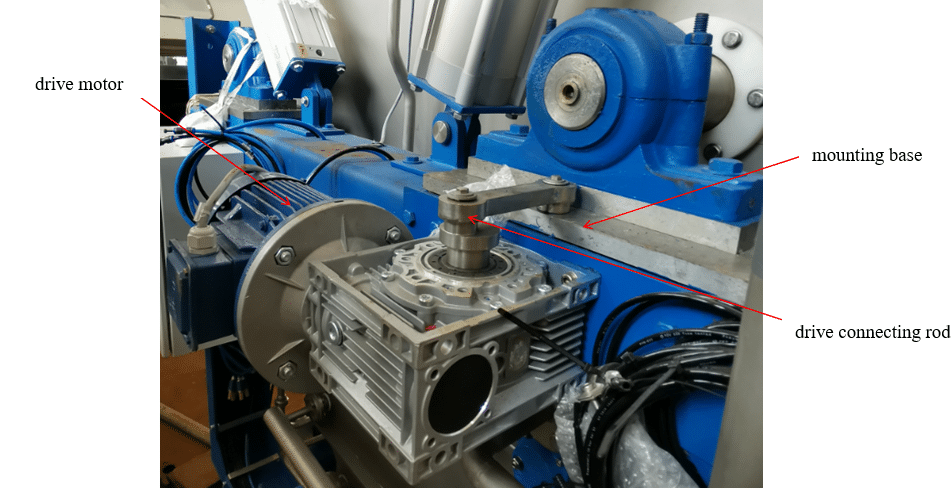

Main roller integral movable traverse structure

(1) Structural features:

- The main roller surface and central support are basically welded and installed, and the structure is relatively simple.

- The main roller moves as a whole through the mounting bases at both ends to achieve traverse movement.

(2) Working principle:

- By moving the mounting bases at both ends of the main roller, the main roller as a whole moves forward and backward along the axis.

(3) Advantages and Disadvantages:

- Advantages: Avoids dyeing liquid from entering the main roller, and the structure is relatively simple.

- Disadvantages:

- High requirements for the stability and wear resistance of the main roller mounting base;

- the gap between the main roller and the cylinder will gradually increase over time, resulting in reduced sealing;

- this structure is not suitable for high-temperature and high-pressure jigger dyeing machines.

3)Application scenarios:

Mostly used in normal temperature jigger dyeing machines.

Comparison of two main roller traverse structures in jigger dyeing machine

| Comparison Item | Roller surface moving type | Main roller integral moving type |

| Structure | Central support is fixed, the roller surface moves along the axis | Weld the roller surface with the support. Move the roller as a whole by the base at both ends. |

| Principle | Driven by motor, screw rod and shift fork, the roller surface is pushed by lever principle | Move the bases at both ends to drive the main roller to move |

| Advantages | Sealing is easy to solve, and the stroke can be controlled by the motor | Prevent dye liquid from immersing, simple structure |

| Disadvantages | The roller support is difficult to seal and clean, and the shift fork requires maintenance | High requirements on the base, large gaps and reduced sealing |

| Applicable | High temperature and high pressure jigger dyeing machine | Normal temperature jigger dyeing machine |

The traverse movement of the main roller of the jigger dyeing machine is a very practical function. The above two main roller traverse movement structures of the jigger dyeing machine each have their own characteristics and applicable scenarios. In practical applications, it is necessary to select the appropriate structure according to specific needs and conditions to ensure the dyeing effect and stable operation of the equipment.