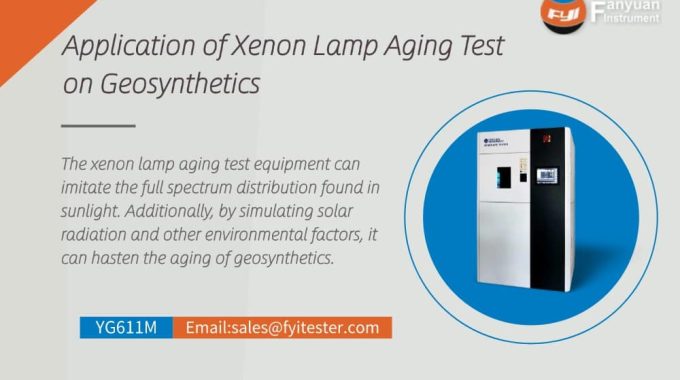

Application of Xenon Lamp Aging Test on Geosynthetics

With the continuous development of civil engineering and construction industries, geosynthetics are increasingly used in various fields. However, owing to environmental factors, the performance of geosynthetics may gradually decline, thus affecting their service life. In order to ensure the stability and safety of geosynthetic materials in engineering, it is crucial to conduct regular aging tests.

Generally speaking, aging tests can be divided into natural aging and artificial accelerated aging tests. The natural aging test is extremely simple to operate and very low-cost, but it requires a lot of time to conduct the test. However, the application of geosynthetics in engineering may last for hundreds of years, and it is impossible to achieve this aging process through natural aging methods.

The xenon lamp aging test equipment can imitate the full spectrum distribution found in sunlight. Additionally, by simulating solar radiation and other environmental factors, it can hasten the aging of geosynthetics. Compared with traditional UV aging tests, xenon lamp aging tests exhibit significant advantages. The acceleration factor of xenon lamp aging tests is considerably higher. Moreover, they can simulate the aging process of geosynthetics in actual environments far more realistically.

Contents

Xenon lamp aging equipment and test principle

Xenon lamp aging equipment

The xenon lamp aging equipment on the market mainly consists of xenon lamp aging test chambers, which have a complex structure and diverse functions. The xenon lamp light source system is the core component, providing stable illumination. The temperature control system can accurately adjust the temperature in the test chamber to simulate different ambient temperature conditions. The humidity control system can control the relative humidity in the chamber to simulate a humid environment. Moreover, there’s a spray system. It has the ability to simulate rainfall. When it does this, the aging test becomes more like the natural climate. This helps us thoroughly test how well geosynthetics can resist aging in complex conditions.

Principle of xenon lamp aging test

The principal underlying the test is rather straightforward. A xenon lamp produces a full spectrum that contains ultraviolet, visible light, and infrared rays. This spectrum is used to irradiate geosynthetic materials. This irradiation leads to photochemical reactions. Additionally, with the help of the combined action of light and heat, physical and chemical changes occur in the materials. This change will cause the strength, toughness and other properties of geosynthetics to gradually decrease, and ultimately affect their service life. By analyzing the results of the test, the stability and durability of geosynthetics under different environmental conditions can be effectively evaluated. These evaluation data lay a reliable reference foundation for engineering design.

Features of xenon lamp aging equipment

High acceleration factor

Compared with the traditional UV aging test, the xenon lamp aging test has a higher acceleration factor. It can more realistically simulate the aging of geosynthetic materials in the actual environment.

Short test cycle

Because the life of xenon lamps is long, the cycle of xenon lamp aging test is relatively short, which helps to improve test efficiency and quickly obtain test results.

Easy to control test conditions

By adjusting the power, irradiation time, temperature, humidity and other parameters of the xenon lamp, different environmental conditions can be simulated to optimize the test results and meet various research needs.

High reliability of test results

The xenon lamp aging test has good repeatability and reproducibility, and can provide a reliable reference for engineering design.

Application purpose of xenon lamp aging test on geosynthetic materials

Evaluate weather resistance

Geosynthetics exposed outdoors for a long time are affected by a variety of environmental factors such as sunlight, rain, and temperature changes. Eventually, their performance will gradually decline. The xenon lamp aging test can quickly evaluate the weather resistance of materials under lighting conditions. Through the test, the color change during the aging process is observed, and the strength loss is tested, etc., which provides a basis for judging the performance changes of the material in the actual use environment.

Predicted service life

Based on the changing rules of material properties in the xenon lamp aging test and combined with actual environmental parameters, we can establish a mathematical model to predict the performance changes of geosynthetic materials in the natural environment. Engineers can choose more appropriate solutions in engineering design and material selection to ensure long-term stable operation of the project.

Quality control and product research and development

In the production process of geosynthetics, the xenon lamp aging test is also an important quality control method. Manufacturers use tests to check whether the products meet the expected aging resistance standards and improve products that do not meet the standards. In the new product development stage, this test can compare the aging resistance of materials produced with different formulas or processes. Screen out material formulas and production processes with better performance, thus promoting technological progress in the geosynthetic materials industry.

Examples of common geosynthetics

Here are some examples of common geosynthetics that require xenon lamp weathering tests:

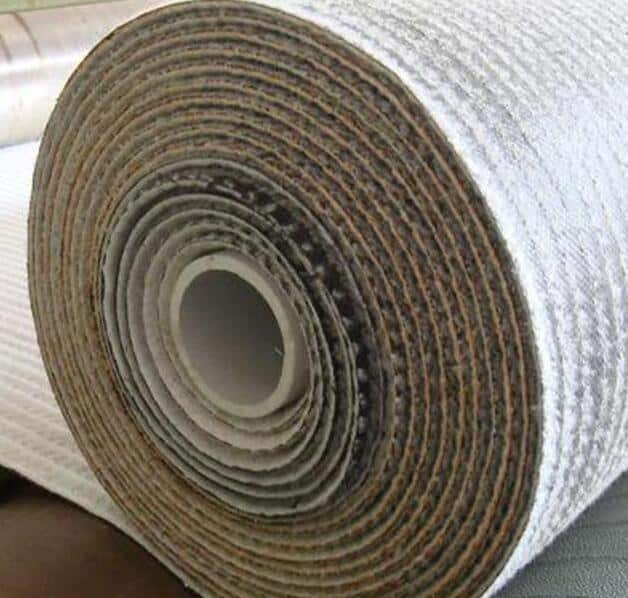

PP Geotextiles

PP geotextiles are widely used in civil engineering, for example as drainage materials or filter layers. Xenon lamp weathering tests can help evaluate their resistance to sunlight exposure in outdoor environments and ensure their stability in long-term use.

PET Geotextiles

Polyester materials are known for their excellent tensile strength and corrosion resistance and are often used to reinforce and protect soils. Through xenon lamp weathering tests, their degradation under sunlight exposure can be detected to optimize their service life.

Geomembranes

Geomembranes are often used for waterproofing and isolation, and they need to withstand long-term UV exposure. Using xenon lamp testing can simulate the impact of the natural environment and ensure the reliability of the material in actual applications.

Composite Geosynthetics

These materials combine multiple functions and are often used in complex civil engineering projects. Xenon lamp weathering tests can comprehensively evaluate the durability of different components under UV and temperature changes.

In short, as an efficient and reliable geosynthetics aging test method, the xenon lamp aging test has been widely used at home and abroad. Through in-depth research and continuous improvement, it is expected to provide more powerful support for the development of my country’s civil engineering and construction industries.