Tension control mechanical structure of jigger dyeing machine

The jigger is a kind of equipment used for textile dyeing. It has a high degree of automation, is environmentally friendly and energy-saving, and can realize small batches and multiple varieties of dyeing. It is widely used in the textile dyeing industry.

The jigger dyeing machine is divided into the main roller, dye tank, tension frame, guide roller, heating system, circulation system, additional tank system, debatching device, control system, and other parts. Through a series of precise mechanical structures and control systems, the jigger dyeing machine realizes precise control of the fabric dyeing process.

Among them, the tension frame is a key component of the tension control part of the jigger dyeing machine. Its main function is to ensure the flatness and uniformity of the fabric during the dyeing process by adjusting and controlling the tension of the fabric so as to achieve a higher quality dyeing effect.

Contents

Structural composition of tension frame of common jigger dyeing machines

At present, the structures of tension frames of jigger dyeing machines on the market can be mainly divided into two types: horizontal chevron-shaped type and vertical expanded guide roller type.

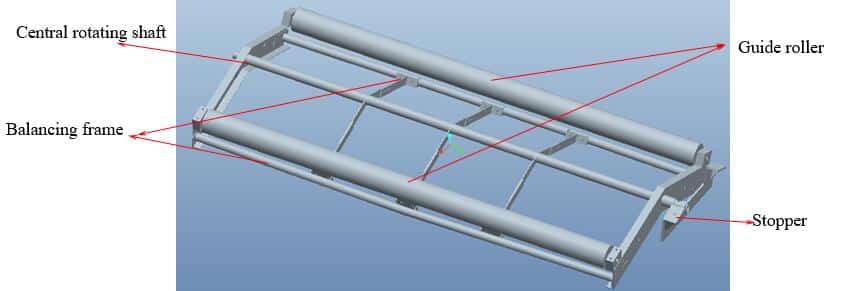

Horizontal chevron-shaped type

- The horizontal chevron-shaped type tension frame of the jigger dyeing machine consists of a rotating shaft, balancing frame, a guide roller, and a shock absorber. The overall shape resembles a chevron from the side, which is named after it.

a) Rotating shaft and balancing frame: The horizontal chevron-shaped type tension frame is equipped with a central rotating shaft, and balancing frames are installed symmetrically on both sides. During the dyeing process of the jigger dyeing machine, when the fabric changes direction, the tension frame can rotate along the central rotating shaft.

b) Guide roller: A set of guide rollers is installed on the balance frame of the tension frame to guide the movement of the fabric.

c) Stopper and shock absorber: A stopper is installed at one end of the central rotating shaft to limit the rotation range of the tension frame. The stopper is equipped with a shock absorber to prevent the tension frame from rotating too fast when the fabric changes direction and the stopper hits to produce a large noise.

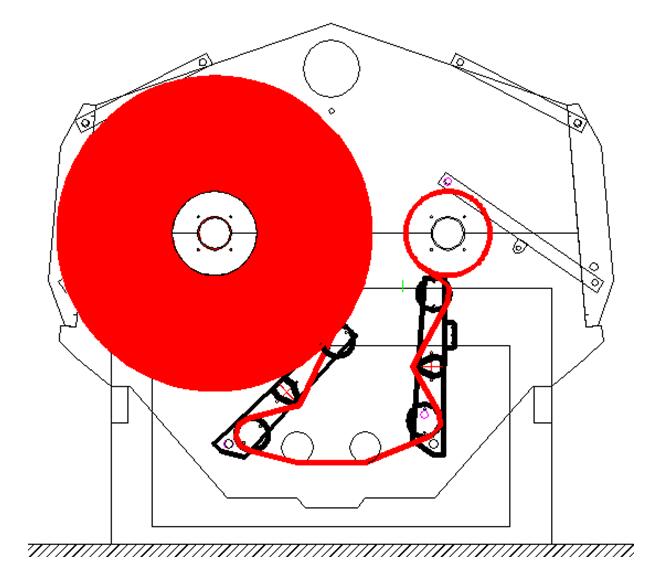

Vertical expanded guide roller type

- The vertical expansion guide roller-type tension frame of the jigger dyeing machine is composed of a spring, a swing shaft, a swing arm, a guide roller, and an expansion rod. It not only can adjust the tension but also has the function of expanding.

a) Spring, swing shaft, and swing arm: Swing arms are provided on both sides of the vertical expanded guide roller tension frame. The bottom end of the swing arm is installed on the swing shaft, and the upper end is connected to the spring so that the tension frame can automatically adjust according to the thickness and elasticity of the fabric.

b) Expanding rod: A expanding rod is installed in the middle of the swing arm of the tension frame. The cross section of the expanding rod is triangular or pentagonal as a whole. The triangular end is in contact with the fabric. The expanding rod is arc-shaped as a whole, which can play the role of scraping liquid and expanding the width.

c) Guide rollers: The vertical expansion guide roller type tension frame is equipped with two sets of fabric guide rollers, which are located at the upper and lower ends of the swing arm respectively. The fabric passes through the two sets of fabric guide rollers and the expansion rod, which can not only guide the movement but also make the fabric in close contact with the arc-shaped expansion rod, thereby enhancing the effectiveness of the expansion rod.

Diagram of vertical expanded guide roller type tension frame of jigger dyeing machine

Working principle of tension frame of common jigger dyeing machines

Working principle of horizontal chevron-shaped type tension frame:

- The horizontal chevron-shaped tension frame of the jigger dyeing machine mainly maintains balance through the gravity at both ends. The guide rollers on both sides are in contact with the fabric respectively. During the movement of the fabric, the friction between the fabric and the guide roller will cause the tension frame to change in shape. The fabric tension is adjusted by the tension frame’s own gravity and the friction generated by the fabric.

Working principle of a vertically expanded guide roller tension frame:

- The vertical expansion guide roller tension frame of the jigger dyeing machine mainly relies on springs to adjust the tension. The fabric passes through the lower guide roller, expansion rod and upper guide roller in sequence. During the movement, the fabric will pull the upper guide roller in the direction of the fabric movement, and the spring will pull the swing arm in the opposite direction, so that the fabric can always be in a state of tension. The size of the tension is related to the thickness and elasticity of the fabric. And when the fabric passes through the expansion rod, the arc triangle will expand the fabric to avoid wrinkling and creases.

Advantages and disadvantages of common jigger dyeing machine tension frames

| horizontal chevron-shaped type tension frame | vertical expanded guide roller type tension frame | |

| advantage | 1. Simple structure, low manufacturing cost and maintenance difficulty; 2. Small vertical space occupation, convenient for workshop layout; 3. Provide more stable tension. | 1. Good expansion effect, making the fabric width and tension more uniform; 2. High tension control accuracy, suitable for high-end fabrics; 3. Effectively reduce fabric creases. |

| disadvantage | 1. Poor adaptability to light and thin fabrics, easy to wrinkle or stretch excessively; 2. Color difference between the edges is prone to occur when the fabric width is large. | 1. High equipment cost and complex maintenance; 2. Large space occupied and high requirements for factory height; 3. Complex operation and training required. |

Other tension frames of jigger dyeing machines

- In addition to the above two common tension frames for jigger dyeing machines, various manufacturers have also tried some other forms of tension frames, such as:

- Pulley tension frame: Adjust fabric tension through pulleys and ropes.

- Air-floating tension frame: Air-floating bearings are used to support the coiled material, which can provide a more stable tension.

- Magnetic tension frame: Uses magnetic force to maintain tension.

- Cylinder tension frame: Use the thrust generated by the cylinder to adjust fabric tension.

- Motor-type tension frame: adjusts fabric tension through motor drive.

- Hydraulic tension frame: adjusts fabric tension through a hydraulic system.

- In addition, there are some special types of tension frames for jigger dyeing machines, such as customized tension frames for specific fabrics or specific process needs. The design and manufacture of these tension frames are usually determined according to specific production requirements and process conditions.

In conclusion, when choosing the tension frame of the jigger dyeing machine, it is necessary to comprehensively consider factors such as the type, thickness, elasticity of the fabric and the requirements of the dyeing process. At the same time, it is also necessary to pay attention to the structural design, material selection, manufacturing accuracy and other aspects of the tension frame to ensure that it can meet production needs and have a long service life.