Textile Testing with a High Volume Instrument (HVI)

For cotton fiber testing, there are 6-items of cotton fiber properties as below, which should be checked normally:

1. Length

2. Maturity (Micronaire value)

3. Moisture

4. Strength

5. trash

6. Color

HVI can do all these 6-test in one machine, and normal testing use separate testing machines to check each property.

After check these 6 properties of cotton fiber, then can classify cotton to different grade, which is very important to its price. Most famous HVI is from USTER.

Contents

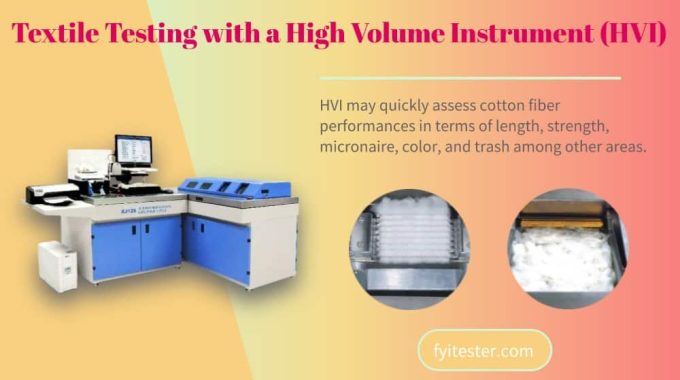

HVI in our company

Our company’s HVI model is XJ128. The fast, multipurpose XJ128 Rapid Fiber Tester blends optics, mechanism, electrics, air compression, and computer to evaluate cotton fiber performance. It may quickly assess cotton fiber performances in terms of length, strength, micronaire, color, and garbage, among other areas. Average length, upper half average length, strength, elongation, maximum breaking force, Micronaire, maturity index, reflectivity, yellow depth, color grade, garbage numbers, trash area percent, trash grade, and other information are also provided. It can address the need for structural reform in cotton quality testing and enhance the reliability and scientific integrity of notarized testing. It’s critical to evaluate cotton testing departments’ products impartially and objectively, assist textile companies with cotton sorting, and maximize the use of cotton resources.

It is applied for cotton testing departments, textile enterprises, colleges, cotton breeding departments, and institutes to test cotton fiber performances.

Module function and working principle of HVI

- The barcode reader scans bale tags and immediately enters the information into the program.

- Balance: Used to weigh specimens for Micronaire module.

- The Micronaire module:

- Micronaire was tested for air pressure difference using a single compressed air flow and compensated for quality differences.

- The maturity index was determined using Micronaire and specific strength.

- The printer can print the things listed below.

- Set calibration settings.

- Calibration results data.

- Test data and statistical outcomes.

- Create test result curves.

- Color/trash module:

- Calculate color grade based on reflectivity (Rd) and yellow depth (+b) by spectral component analysis;

- Report color grade based on these values in accordance with US or Chinese color grade standards;

- Measure trash using CCD camera, image processing, and software analysis methods to determine trash numbers TC, trash area percentage TA, and trash grade TG on cotton surface.

- Module of length and strength:

- Length: Using the shadow-casting technique in accordance with the shadow-casting curve, measure the fiber average length (Lm), the average length of the upper half (Luhm), and the length uniformity index (UI); The shading curve and empirical formula (optional for the US and China) were used to determine the short fiber index, or SFI.

- Strength: Determine the exact strength (Str) by calculating the force required to break a certain amount of fiber.

- Elongation: Determine the length of the fiber (Elg) based on the breaking distance; the stretching curve may be produced.

Features of HVI testing

- Automatic sampling is employed for length/strength measurements, which minimizes the influence of manual sampling. The automated sampler has a twin sampling barrel, and two comb samples are collected at the same time. The sample platen is finger-shaped to resemble manual sampling.

- System measurement of each module in parallel, with great efficiency.

- Optical zero automated adjustment and tracking correction, low starting preheating time, and high stability.

- Maintenance is simplified thanks to the online problem diagnostic tool.

- Color light power supply is under constant current regulation, and the color test results are stable.

- Double color/trash modules are checked concurrently, resulting in excellent efficiency and minimal labor effort.

- Chinese and American standards allow for the categorization of staple fibers and colors.

- An automatic cotton matching system can be chosen to assist textile businesses in cotton matching.

How to select HVI or normal fiber testing machine?

HVI, it is easy to operate, and need less manpower, high efficiency

But its price is very high. For USTER HVI machine, its cost is about 10 times than normal testing machines in China market. Even our HVI is 4times of normal (separate testing ) machines.

The one of biggest supplier, American Cotton-Incorporated, as I know, they do not use HVI testing for cotton fiber. They buy some separate testing machines from us, such as KX730, fiber length, etc.

In China, in 2017, I used to visited Professor Yao, who is Academician of Chinese Academy of Engineering, and top scientist of Cotton fiber in China, http://www.cae.cn/cae/html/main/colys/68999420.html, you can visit this page for more details.

He told me:

1. In china, we will stop HVI testing step by step, as some testing result is not acceptable, so China want to develop new system to evaluate cotton and make classification of cotton fiber.

2. In HVI, the staple fiber length is not accurate, but this value is very important to yarn spinning.

This is why America Cotton incorporated buy KX 730 from us to check the fiber length instead of using HVI to check fiber length.

3. Fiber strength, the testing result is not stable and reproducible due to HVI clamping system.

4. Now more and more customers need check fiber diameter, HVI can not do this job. If necessary, ginning factory can buy one camera system to check diameter by camera with the help of PC and its software.

Anyway, from my eyes, separate testing machines, at this time, it is the best choice of ginning factory, even some yarn spinning mill.

As this solution is

—– low cost solution with much better testing result

—–you can select any package of testing, for example, fiber length, micronaire, moisture content, as these 3-4 items is very important.

But: If using separate testing machines, need more operators, and more training on operators. It is another expense.

:The-most-valuable-guidance-680x380.jpg)