Everything You Need to Know About Color Fastness to Washing

Last Updated: April 29. 2025

Color fastness to washing refers to a fabric’s ability to retain its original color during laundering without fading or staining other garments. Poor textile color retention solutions can lead to cross-staining, impacting both aesthetics and functionality. This article explains testing standards, methods, and strategies to improve color fastness to washing techniques.

Almost all textiles are washed in people’s everyday lives. The fabrics are cleaned in a washing liquid at a certain temperature. The dye will come off the textile due to the action of the washing liquid, and ultimately the original color of the textile will alter, which is known as discolouration. At the same time, the dye in the washing liquid will contaminate and modify the color of other fabrics, a process known as staining.

Whether or not the color fastness to washing is excellent or bad, it will effect the staining of other garments worn on the body, or it will stain other clothes when washed with other clothes.

Contents

The standard of washing fastness

Color fastness to washing is one of the common test items for textile color fastness. It mainly tests the color fastness of textiles used in clothing and home textiles after simulating one or more household and commercial launderings. Common test standards are ISO 105 C06 and AATCC 61:2010.

ISO 105 C06

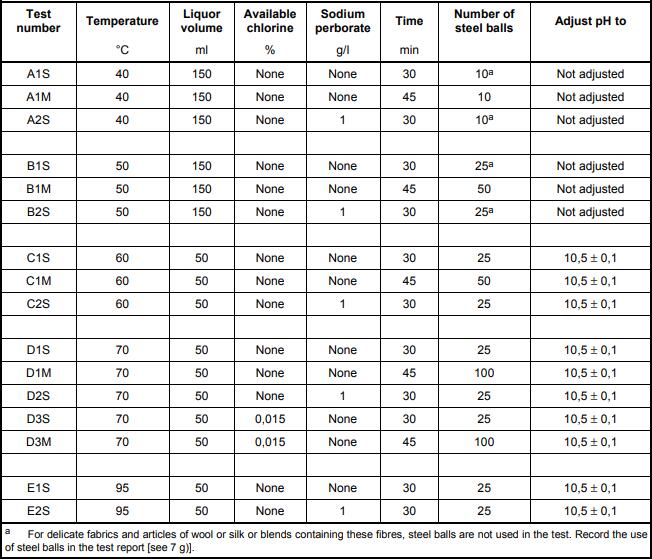

ISO 105 C06 contains a total of 16 different test procedures from A1S to E2S.

Wherein, “S” refers to single commercial or domestic laundering. “M” means multiple washes, or about five home or commercial washes. Their specific test conditions are as follows.

| Test number | Temperature ℃ | Liquor volume ml | Available chlorine % | Sodium perborate g/l | Time min | Number of steel balls | Adjust pH to |

| A1S | 40 | 150 | None | None | 30 | 10a | Not adjusted |

| A1M | 40 | 150 | None | None | 45 | 10 | Not adjusted |

| A2S | 40 | 150 | None | 1 | 30 | 10a | Not adjusted |

| B1S | 50 | 150 | None | None | 30 | 25a | Not adjusted |

| B1M | 50 | 150 | None | None | 45 | 50 | Not adjusted |

| B2S | 50 | 150 | None | 1 | 30 | 25a | Not adjusted |

| C1S | 60 | 50 | None | None | 30 | 25 | 10,5±0,1 |

| C1M | 60 | 50 | None | None | 45 | 50 | 10,5±0,1 |

| C2S | 60 | 50 | None | 1 | 30 | 25 | 10,5±0,1 |

| D1S | 70 | 50 | None | None | 30 | 25 | 10,5±0,1 |

| D1M | 70 | 50 | None | None | 45 | 100 | 10,5±0,1 |

| D2S | 70 | 50 | None | 1 | 30 | 25 | 10,5±0,1 |

| D3S | 70 | 50 | 0,015 | None | 30 | 25 | 10,5±0,1 |

| D3M | 70 | 50 | 0,015 | None | 45 | 100 | 10,5±0,1 |

| E1S | 95 | 50 | None | None | 30 | 25 | 10,5±0,1 |

| E2S | 95 | 50 | None | 1 | 30 | 25 | 10,5±0,1 |

a For dlicat fabics and aricles of wool or sik or blends containing these fibres, steel balls are not used in the test. Record the use of steel balls in the test report [see 7 g)]:

AATCC 61:2013

AATCC 61:2013 includes five test methods, however the most commonly used are 1A and 2A. 1A is appropriate for hand washing at 40°C and 2A is appropriate for machine washing at 49°C.

The 3A program, which is less often used, tests clothes at 71°C, whereas 4A and 5A add the chlorine-based bleach sodium hypochlorite to the wash water. The following are the test conditions.

| Test No. b | ℃(±2℃) | ℉(±2℉) | Total Liquor Volume (mL) | Percent Powder Detergent of Total Volume | Percent Liquid Detergent of Total Volume | Percent Available Chlorine of Total Volume | N0. of Steel Balls | No. of Rubber Balls | Time (Min) |

| 1A | 40 | 105 | 200 | 0.37 | 0.56 | None | 10 | 0 | 45 |

| 1Bc | 31 | 88 | 150 | 0.37 | 0.56 | None | 0 | 10 | 20 |

| 2A | 49 | 120 | 150 | 0.15 | 0.23 | None | 50 | 0 | 45 |

| 3A | 71 | 160 | 50 | 0.15 | 0.23 | None | 100 | 0 | 45 |

| 4A | 71 | 160 | 50 | 0.15 | 0.23 | 0.015 | 100 | 0 | 45 |

| 5A | 49 | 120 | 150 | 0.15 | 0.23 | 0.027 | 50 | 0 | 45 |

aRefer to Section 9 for objectives for each test method.

bAll Tests includ an atenate use for 2003 AATCC Standard Liquid Detergent.

cTest 1B provides for the use of White Rubber Balls instead of Stainless Steel Balls.

Determination of color fastness to washing(depend on ISO 105 c06)

Purpose

Learn how fabrics fade and stain other washes in the wash.

Preparation

ECE, IEC, WOB (as required by customers), sodium perborate, sodium carbonate 1g/l, monofilament lining, multifiber lining (DW: low temperature lining; TV: high temperature lining), ISO standard gray scale, washing fastness tester.

Sampling

4cm×10cm (including all colors, if the colors are scattered, prepare a few more pieces). When sewing, the front side is sewn along the wool fiber direction and the short side. Yarn and loose fibers should be stitched on all four sides.

Operation steps

1. Firstly adjust the humidity of the sample with the standard atmosphere (20±2℃ 65±2%) for 4 hours.

2. Select the temperature, preheat the test solution in the steel cup for 5-10 minutes, and then put the test cloth. (The test method is based on the customer’s requirements, and the corresponding test type is selected.) After the test, wash it twice with 100ml of distilled water at 40°C, each time for 1min. Shake off excess water and dry at a temperature not higher than 60°C.

A, B methods can add steel balls according to customer requirements, and indicate the number of steel balls. And pH needs to be adjusted with 1g/l sodium carbonate

Rating

Rated after 1 hour of humidity conditioning in a temperature chamber and humidity chamber. The sample and the ISO standard gray scale should be placed at 45° to the desktop, and the line of sight and the fabric is 90°, and two people must be rated at the same time, and the average value of the results is 5.0.

The way to improve color fastness to washing

The color fastness to washing of printed and dyed fabrics is related to the chemical structure of the dye, the combination of the dye and the fiber, and the dyeing process. Therefore, the color fastness to washing of textiles can be improved by these methods.

Select the suitable dyes

Generally, dyes with water-soluble groups have poorer soaping fastness than dyes without water-soluble groups, and the more hydrophilic groups in the dye molecule, the lower the color fastness to washing. Such as acid dyes and direct dyes, because they contain more water-soluble groups, their color fastness to soaping is low. The dyes such as vat and sulfur do not contain water-soluble groups, and have high color fastness to washing. Therefore, choosing a suitable dye can improve the color fastness to washing.

Strengthen the binding force of dye and fiber

The stronger the binding force of the dye to the fiber, the higher the color fastness to washing. Such as acid mordant dye, acid mordant dye and direct copper salt dye, due to the intervention of metal ions, the combination between the dye and the fiber is strengthened, and the color fastness to washing is improved. Another example is that reactive dyes are covalently bonded to fibers during color fixation, and the dyes become part of the fibers. Therefore, the color fastness to washing is better.

In addition, the color fastness to washing of the same dye on different fibers is different. For example, the color fastness to washing of disperse dyes on polyester is higher than that on nylon. This is because polyester has strong hydrophobicity and tight structure.

Choose right dyeing process

The color fastness to washing is closely related to the dyeing process. If the dye is poorly dyed and the floating color cannot be removed, the color fastness to washing will decrease.

FAQs

Q1: What causes poor color fastness to washing?

Weak dye-fiber bonds, improper dye selection, or incomplete post-dyeing rinsing.

Q2: How do ISO 105 C06 and AATCC 61 differ?

ISO uses varied test conditions (e.g., steel balls, bleach), while AATCC focuses on regional laundering practices.

Q3: Can fabric type affect wash fastness?

Yes. For example, disperse dyes show higher textile color retention solutions on polyester than nylon.

Q4: How to test for staining during washing?

Use multifiber adjacent fabric during testing and rate staining against ISO gray scales.

Q5: Are there eco-friendly dyes with high wash fastness?

Yes. Reactive and vat dyes offer both sustainability and compliance with AATCC 61:2013 color fastness standards.

Conclusion

Improving color fastness to washing requires selecting the best dyes for high wash fastness, optimizing dyeing processes, and adhering to global standards like ISO 105 C06 washing fastness test. Regular testing ensures long-lasting fabric quality and consumer satisfaction.

Leave a Reply

You must be logged in to post a comment.

Really nice and interesting post. I was looking for this kind of information and enjoyed reading this one.

Thank a lot. You have done excellent job. I enjoyed your blog . Nice efforts

Your blog is great. I read a lot of interesting things from it.

Your style is very unique compared to other people I have read stuff from. Thanks for posting when you have the opportunity, Guess I’ll just book mark this page.

What I love about your writing style is that it’s both engaging and educational.

See how the author effortlessly weaves together facts, anecdotes, and opinions.