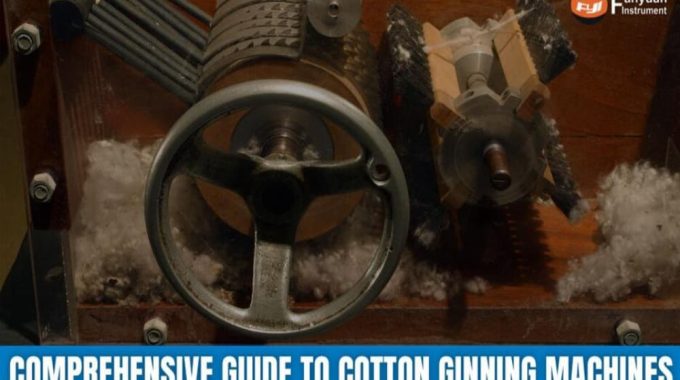

Comprehensive Guide to Cotton Ginning Machines

Ever wondered how cotton goes from fluffy white bolls to the fabric in your clothes? It’s all about cotton ginning. This is the heart of textile manufacturing. It turns raw cotton into clean fiber ready for spinning and weaving.

Cotton ginning machines are the workhorses of this industry. They separate cotton fibers from seeds and remove dirt and debris. Without these machines, cotton processing would be slow and expensive. The technology has come a long way since 1793. That’s when Eli Whitney invented the first cotton gin.

Today’s machines are innovative and efficient. They use computers and sensors to work perfectly. They can process thousands of pounds of cotton per hour. Understanding these machines is crucial whether you work in research, teach at universities, or run textile operations.

This guide will teach you everything about cotton ginning technology. You’ll learn how to choose the right equipment and run it successfully.

Contents

- 1 What is Cotton Ginning?

- 2 History of Cotton Ginning

- 3 Types of Cotton Ginning Machines

- 4 Working Principles and Testing Methods of Cotton Ginning Equipment

- 5 Ginning Equipment Performance and Technical Specifications

- 6 Machine Quality and Brand Reputation in Cotton Ginning

- 7 Industry Testing Standards and Compliance Requirements

- 8 Price, Cost-Effectiveness, and Maintenance Requirements

- 9 Conclusion

What is Cotton Ginning?

Cotton ginning is simple. It separates cotton fibers from seeds. Think of it like removing apple seeds from the fruit. Raw cotton comes from the field with seeds inside. These seeds must come out before making fabric.

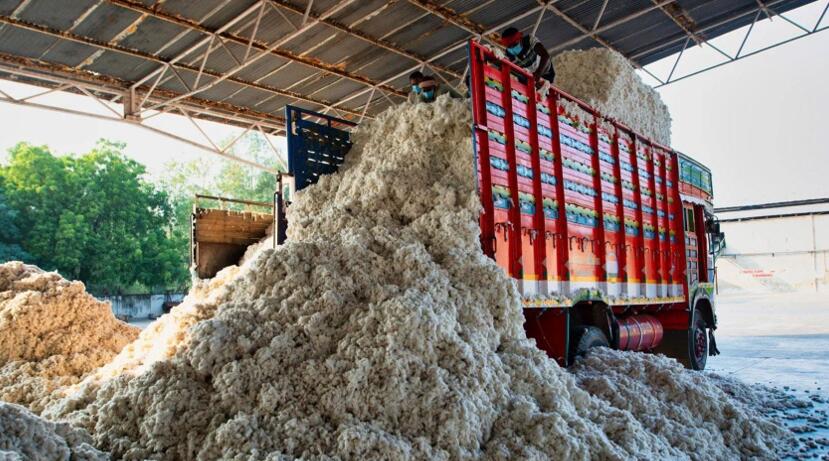

The cotton ginning machine does this job. It pulls the white cotton fibers away from the brown seeds. The machine also removes dirt, leaves, and sticks. This cleaning makes the cotton pure and ready for use.

The process works in steps. First, cotton goes into the machine. Then, the mechanical parts grab the fibers. They pull them through small openings. The seeds are too big to follow. They fall away separately. Clean cotton fibers come out the other side. These fibers then get pressed into bales for shipping.

History of Cotton Ginning

Cotton ginning started 6,000 years ago. Ancient people in India and Egypt used wooden rollers. They rolled cotton by hand to remove seeds. This was very slow work.

Everything changed in 1793. Eli Whitney invented the cotton gin in America. His machine used wire hooks and brushes. It worked 50 times faster than hand-picking. This made cotton farming very profitable.

The Industrial Revolution brought steam power. Machines got bigger and faster. In the 1800s, saw ginning was invented. These machines used spinning saw blades.

The 1900s brought roller gins for premium cotton. These were gentler on the fibers. Today’s machines use computers and sensors. They can process thousands of bales per day. Modern gins are fully automated and very efficient.

Types of Cotton Ginning Machines

There are three main types of cotton ginning machines today. Each type works differently and has special uses. The choice depends on your cotton type and processing needs. Let’s explore each machine type.

| Feature | Roller Ginning | Lab Ginning DW040 | Saw Ginning |

| Processing Speed | 180-450 kg/hour | 10-50 grams/sample | 3,400-5,675 kg/hour |

| Best For | Long-staple cotton | Research & testing | Short-staple cotton |

| Fiber Quality | Excellent (95%+ preserved) | Research accuracy | Good (2-5% damage) |

| Energy Use | 8-12 kWh/bale | Very low | 12-18 kWh/bale |

| Maintenance | Moderate | Low | High |

1. Roller Ginning Machine

Roller ginning machines are the gentlest for cotton processing. They have leather-covered rollers and sharp knives to separate fibers from seeds. The roller grips the cotton fibers, and the knife returns the seeds. This preserves fiber quality very well.

These work best with long-staple cotton varieties. They process cotton slowly but carefully. The gentle action keeps fibers long and strong. This makes the cotton more valuable. Many premium cotton producers use roller gins.

The machines can be single or double roller types. Double roller gins work twice as fast. They process 350-450 kg per hour. Single roller gins process 180-220 kg per hour. Both are excellent for fiber quality. They consume less power than other gin types.

Features:

- Gentle fiber handling preserves cotton quality

- Best for long staple and premium cotton varieties

- Low power consumption compared to saw gins

- Minimal fiber damage during processing

- Requires skilled operators for optimal performance

2. Lab Ginning Machine DW040

The Lab Ginning Machine DW040 is for research and testing purposes. It processes small cotton samples accurately. Universities and research centers use these machines daily. They test new cotton varieties and study fiber properties.

This machine can handle samples from 10 to 50 grams. It works like a bigger commercial gin. The results help predict how cotton will perform in full-sized machines. Quality control labs use it to check cotton grades.

The DW040 is very precise and consistent. It gives the same results every time. The machine is compact and fits on laboratory benches. It’s easy to clean between different cotton samples. Many textile companies use it for quality testing.

Features:

- Processes small samples (10-50 grams) with high accuracy

- Ideal for research institutions and quality control labs

- Compact desktop design saves laboratory space

- Easy sample changing and cleaning between tests

- Gives data for cotton variety evaluation

3. Saw Ginning Machine

Saw ginning machines are the workhorses of commercial cotton processing. They have rotating circular saw blades to pull fibers through metal ribs. The saws spin very fast and catch cotton fibers. Brushes remove the cotton from the saw teeth. These processes cotton much faster than roller gins. Large saw gins can do 15-25 bales per hour. They work best with short and medium-staple cotton. Fast processing makes them very profitable for big operations.

Saw gins are more aggressive than roller gins. They may damage some fibers during processing. But they clean cotton very well and remove trash effectively. Most commercial cotton processing uses saw ginning technology. They consume more power but process more cotton.

Features:

- High speed (15-25 bales per hour)

- Excellent trash and debris removal

- Best for short and medium staple cotton

- Automated lint removal with brush systems

- Higher power consumption but more throughput

Working Principles and Testing Methods of Cotton Ginning Equipment

Cotton ginning machines work by using mechanical force to pull fibers from seeds. Understanding how they work will get you better results. Testing these machines will ensure they meet quality standards and work properly.

1. Working Principles of Cotton Ginning

Cotton ginning uses controlled force to pull fibers from seeds. The natural bond between fiber and seed must be broken. Different machines do this job differently.

Roller ginning machines grip cotton fibers with leather rollers. A sharp knife holds the seeds in place. The roller pulls fibers through a small gap. Seeds are too big to follow. This gentle method keeps fibers long and strong.

Saw ginning machines use spinning saw blades. The saws catch fibers and pull them through metal slots. Brushes clean the cotton off the saw teeth. This method is faster but may damage some fibers.

Both systems need proper settings. Feed rate controls how fast cotton goes into the machine. Moisture content should be 6-8% for best results. The temperature must be safe to prevent fiber damage. Speed and pressure settings can be adjusted for different cotton types.

2. Testing Methods of Cotton Ginning

Testing cotton ginning machines will ensure they work right and produce good cotton. These tests check machine performance and fiber quality. Regular testing will maintain high standards.

Performance testing will measure how well the machine separates fibers from seeds. Ginning rate will test how much cotton the machine can process per hour. Standard cotton samples will be used for fair comparison. Multiple tests will give you reliable results.

Separation efficiency testing will check if all fibers are removed from seeds. Ginned seeds will be examined for leftover fibers. Good machines will remove almost all fibers. Poor separation means the machine needs adjustment.

Quality testing will examine the cotton fibers after ginning. Length testing will measure fiber length and uniformity. Strength testing will test how strong the fibers are. Micronaire testing will look at fiber fineness and maturity. Color testing will check for stains or damage.

These tests use special equipment called HVI systems. Trained technicians will run the tests and read the results. The data will help you adjust machine settings and cotton quality.

Ginning Equipment Performance and Technical Specifications

Every cotton ginning machine has its own performance and technical features. These numbers help you choose the right machine for you. Knowing these specs will get you good value and good results.

1. Processing Capacity and Speed

Processing capacity is how much cotton a machine can process per hour. Roller gins process 180-450 kg of seed cotton hourly. Single roller gins process 180-220 kg per hour. Double roller gins process 350-450 kg per hour.

Saw gins are way faster than roller gins. Industrial saw gins process 15-25 bales per hour. Each bale is 227 kg. So big saw gins can process 3,400-5,675 kg per hour. They are profitable for big operations.

Processing speed depends on cotton quality and machine settings. Good cotton with the proper moisture processes faster. Cotton with trash or wrong moisture slows down processing. Operators must adjust settings according to cotton condition.

2. Energy Consumption and Efficiency

Energy is a significant expense in cotton ginning. Roller gins use 8-12 kilowatt-hours per bale processed. Saw gins use more energy at 12-18 kilowatt-hours per bale. Energy is 40-60% the total processing cost.

Modern machines have energy-saving features. Variable frequency drives adjust motor speed as needed. High-efficiency motors waste less electricity. These can save 15-25% energy. Energy savings often pay for the cost of extra equipment.

Some energy-efficient machines qualify for utility rebates or tax breaks. These incentives make the investment more attractive. Lower energy bills also mean long-term profitability.

Machine Quality and Brand Reputation in Cotton Ginning

Machine quality and brand reputation matter in cotton processing. Good manufacturers provide good equipment and good support. Choosing the right brand means long-term success and good cotton.

1. Leading Equipment Manufacturers

Lummus Corporation is the leader in saw ginning technology. They process large volumes and maintain fiber quality. Lummus uses modular design for easy maintenance. Their control system adjusts settings for best performance.

Continental Eagle excels in both saw and roller ginning machines. They specialize in high-end cotton processing equipment. Their roller gins are famous for long-staple cotton varieties. They focus on continuous improvement through customer feedback.

Both companies have a good customer support network. They offer fast technical support and replacement parts. Training programs help operators get the best out of the machine.

2. Quality Standards and Compliance

Modern ginning operations must follow quality standards. ISO 9001 requires documented procedures for all operations. This includes equipment calibration and maintenance schedules. Following these standards means consistent cotton quality.

ISO 14001 covers environmental protection requirements. Ginning facilities must control dust emissions and manage waste properly. These standards promote sustainable manufacturing—compliance means legal responsibility.

Quality standards build customer confidence. They ensure cotton meets textile industry requirements. Regular audits verify continued compliance with all standards.

Industry Testing Standards and Compliance Requirements

Cotton ginning operations have many safety and environmental rules to follow. These rules protect workers and the environment. Knowing the compliance requirements will help you avoid penalties and run safely.

1. Safety and Regulatory Standards

OSHA (Occupational Safety and Health Administration) has mandatory safety rules. Cotton gins must have emergency stop systems and guards. Safety interlocks prevent accidents with moving parts. Workers need to be trained on safety procedures.

Electrical systems must meet special codes for cotton facilities. Cotton dust is explosive, so electrical equipment needs to be protected. The National Electrical Code (NEC) has specific requirements for these hazardous locations.

Regular safety inspections will ensure continued compliance. Documentation will prove you are following all safety requirements. Safety programs will protect your workers and reduce liability risks.

2. Environmental Protection Requirements

EPA (Environmental Protection Agency) regulates air quality and waste management. Cotton gins must have dust collection systems with 99.5% efficiency. Continuous monitoring systems will track air emissions. Regular reports will document environmental compliance.

Waste management includes cotton trash and maintenance materials. Proper disposal methods will prevent environmental contamination. Some cotton waste can be recycled as soil amendments or livestock feed.

Water protection rules will prevent contamination of groundwater and surface water. Facilities must manage runoff and avoid chemical spills. Environmental compliance will protect natural resources and community health.

Price, Cost-Effectiveness, and Maintenance Requirements

Cotton ginning equipment is a significant investment and has ongoing maintenance costs. Knowing all the costs will help you make smart financial decisions. Proper planning means profitable operations and equipment longevity.

1. Investment and Operating Costs

Roller gins’ cost depends on size and features. Saw gins cost more for industrial units. Advanced automation adds 15-25% to base cost but improves efficiency and quality.

Installation costs add 20-30% to the equipment price. This includes electrical work and concrete foundations. Professional installation ensures optimal performance and maintains warranties. Proper installation also provides safety and regulatory compliance.

Daily operating costs are energy, labor, and supplies. Energy is 40-60% the processing cost. Automated systems need fewer operators than manual systems. Training costs for operators and maintenance staff must be included in the budget.

2. Maintenance Programs and Strategies

Preventive maintenance prevents breakdowns and maintains quality. Daily tasks are lubrication and visual inspections. Weekly maintenance includes detailed component checks. Monthly maintenance includes calibration and wear part replacement.

Modern systems use predictive maintenance technologies. Vibration monitors detect bearing problems early. Thermal imaging finds overheating components. Computer systems track maintenance schedules and equipment performance trends.

Good maintenance programs extend equipment life and reduce unexpected repairs. Regular maintenance means consistent cotton quality. Proper planning minimizes downtime during peak processing seasons.

Conclusion

Cotton ginning machines are a must for modern textile production. They turn raw cotton into clean fibers for manufacturing. This guide covered the main types of ginning equipment and their uses. Roller gins are best for premium cotton. Saw gins handle high volume.—Lab ginning machines are used for research and quality testing.

Understanding how they work helps you use them correctly. Regular testing ensures quality and performance standards. Lummus and Continental Eagle are leading manufacturers of reliable equipment. Following safety and environmental rules protects workers and communities.

The cost of investment varies with machine type. Energy efficiency affects long-term profitability. Proper maintenance extends equipment life and cotton quality. It will be more automated and have better energy efficiency in the future.

Choosing the right ginning equipment requires planning. Consider your cotton types, processing volume, and quality goals. For detailed equipment specs and expert advice, visit our ginning machine solutions at FYI Tester today.