All the information you require about dyeing machines

Garments are made from grey fabric, and then the garments are dyed in the required color and shade. Garment dyeing is the process of coloring ready-to-wear clothes after manufacturing them from grey fabric by cutting and stitching. Usually pants, sweaters, shirts and skirts are dyed after manufacturing is completed. Different types of dyeing machines are used in the textile industry to dye complete garments.

Contents

Working principles of different dyeing machines

Dye bath prepare: The first step is to prepare a dye bath by dissolving dyes and other auxiliary chemicals such as leveling agents, dispersants, and pH adjusters in water. Carefully control the concentration and composition of the dye bath to achieve the desired color and dyeing performance.

Loading of textile materials: The textile materials to be dyed, such as fabrics, yarns, or garments, are loaded into the dyeing chamber or compartment of the dyeing machine. According to the type of machine, materials can be loaded in batches or continuously.

Dye liquor circulation: Once the textile material is loaded, the dyeing liquor is circulated inside the dyeing machine using a pump system. This cycle helps ensure uniform distribution of dye throughout the entire dye bath and promotes the dyeing process.

Temperature control: Using a heating system to control and maintain the temperature of the dye bath at the desired level. Different types of dyes require specific temperature ranges to achieve optimal dye absorption and fixation on textile materials.

Stir: Stirring mechanisms, such as paddle wheels, jets, or rotary drums, are used to stir dye baths and textile materials. Stirring helps to evenly disperse dyes, promote their uniform penetration into textile fibers, and prevent uneven dyeing.

Dye absorption and fixation: When textile materials are immersed in a dye bath, they absorb dye molecules onto the fibers through diffusion and adsorption processes. Depending on the type of dye and fiber, additional chemical treatments such as fixatives or mordants can be used to enhance the absorption and fixation of the dye.

Rinsing and finishing: After the dyeing process is completed, the textile material is rinsed to remove excess dye and auxiliary chemicals. Then, they may undergo additional treatments such as washing, softening, or drying to improve their final appearance and performance.

Factors affecting dyeing

Time — dyeing time and insulation time: The determination of dyeing time is related to the diffusion and combination of the dye on the fiber. Dyeing must have sufficient time for the dye to fully absorb, diffuse, and fix, achieving dyeing balance and obtaining the desired color. If the time is too short, the dye is often not fully dyed, and the expected color cannot be obtained. If the color does not match the sample, it must be repaired and re dyed, which will waste the dye. If there is not uniformity dyeing, there is not enough time for the dye on the fiber to “transfer” and achieve uniform dyeing. Of course, the determination of dyeing time should be appropriate. If the time is too long, sometimes the fabric may change due to prolonged exposure to temperature and chemicals.

Temperature: The temperature is related to the degree of fiber expansion, the performance of dyes (solubility, dispersibility, dyeing rate, dyeing color, etc.), and the performance of additives. Each fiber product and dye has its own optimal dyeing temperature. Improper control of temperature or heating rate can seriously affect the color and uniformity of the dyed product. For example, when dyeing wool with weak acid black BR, the maximum dyeing temperature is 80-95°C, while the maximum dyeing temperature of acid navy blue GGR is 95-100°C. For example, when dyeing acrylic with cationic dyes, the heating rate must be strictly controlled. If the temperature rises too fast, it is very easy to cause dyeing.

PH: PH is also an important factor affecting dyeing color and uniformity. For example, the general dispersed dyeing of polyester is suitable for acidic conditions. If the pH value of these dyes is set to alkaline, the color of some dyes will change, and most disperse dyes will reduce the dyeing rate. For example, when dyeing with acid navy blue GGR, the pH value should not be greater than 3, otherwise the color light will be obviously red. When the pH value changes when the same dye is dyed with the same fiber, the color light will change, and it will affect the levelness. For example, when wool is dyed with acid dyes, the lower the pH value, the more positive charge the wool carries, which speeds up the dyeing speed of negatively charged dyes and increases the possibility of dyeing. The pH value will also affect the reactivity and hydrolysis of the dye. For example, hydrolysis and reactivity of active dyes are related to the pH value. The pH value also affects the properties of the fiber and the performance of the auxiliaries, and ultimately affects the dyeing color and levelness.

Liquor ratio: The ratio of cloth weight to water weight.

Concentration: The dye content in water, measured in g/L. The higher the concentration, the more intense and faster the chemical reaction, and the more obvious the performance.

Additives and water color matching: Color matching is to compare the customer’s samples, comparing the three indicators of hue, lightness and depth. Generally, it is divided into grades 1 to 5, and grade 5 has the smallest color difference.

Applications of dyeing machines

Fabric dyeing: Dyeing machines are commonly used to apply colorants to fabric materials, such as cotton, polyester, silk, wool, and blends. Fabric dyeing machines enable textile manufacturers to produce a diverse range of colored fabrics for apparel, home textiles, upholstery, and other applications.

Yarn dyeing: Yarn dyeing machines are specifically designed to dye yarns before they are woven or knitted into fabrics. These machines allow for the production of dyed yarns with uniform coloration and high color fastness, suitable for various textile applications, including weaving, knitting, and embroidery.

Garment dyeing: Garment dyeing machines are used to color finished garments, such as shirts, t-shirts, jeans, and dresses, after they have been cut and sewn. Garment dyeing enables manufacturers to achieve unique color effects, vintage looks, and special finishes, enhancing the aesthetic appeal and marketability of the finished garments.

Piece dyeing: Piece dyeing machines are employed to dye pre-made fabric pieces or panels, typically in a batch or continuous process. Piece dyeing is commonly used for large-scale production of solid-colored fabrics, such as bedding, curtains, and upholstery fabrics, as well as for dyeing garment components, such as collars, cuffs, and linings.

Tow dyeing: Tow dyeing machines are used to dye tow fibers, which are long continuous strands of synthetic fibers, such as polyester or nylon. Tow dyeing is primarily employed in the production of colored synthetic fibers for various industrial applications, including automotive textiles, filtration fabrics, and technical textiles.

Carpet dyeing: Dyeing machines are utilized in the carpet manufacturing industry to apply colorants to carpet fibers or tufts, resulting in vibrant and durable colored carpets. Carpet dyeing machines enable manufacturers to produce a wide range of carpet designs, patterns, and color variations to meet customer preferences and market demands.

Specialty dyeing: Dyeing machines are also used for specialty dyeing applications, such as tie-dyeing, batik dyeing, resist dyeing, and digital printing. These techniques allow for the creation of unique and artistic textile designs, patterns, and color effects, catering to niche markets and creative industries.

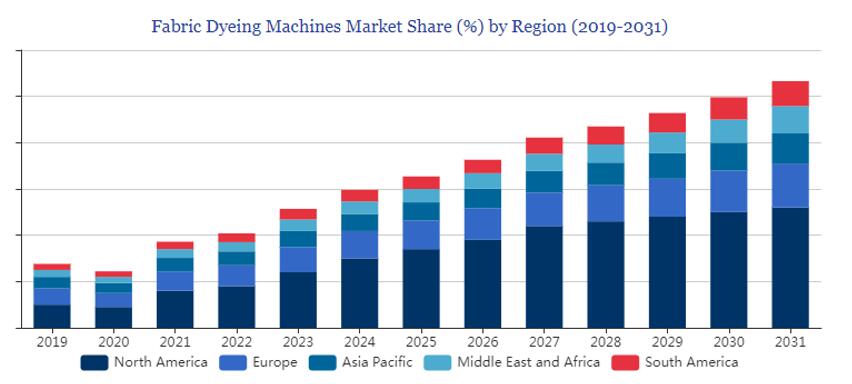

According to Cognitive Market Research, the global fabric dyeing machines market size is USD 1158.2 million in 2024 and will expand at a compound annual growth rate (CAGR) of 5.50% from 2024 to 2031.

- North America held the major market of more than 40% of the global revenue with a market size of USD 463.28 million in 2024 and will grow at a compound annual growth rate (CAGR) of 6.2% from 2024 to 2031.

- Europe accounted for a share of over 30% of the global market size of USD 347.46 million.

- Asia Pacific held the market of around 23% of the global revenue with a market size of USD 266.39 million in 2024 and will grow at a compound annual growth rate (CAGR) of 7.5% from 2024 to 2031.

- Latin America market of more than 5% of the global revenue with a market size of USD 57.91 million in 2024 and will grow at a compound annual growth rate (CAGR) of 4.9% from 2024 to 2031.

- Middle East and Africa held the major market of around 2% of the global revenue with a market size of USD 23.16 million in 2024 and will grow at a compound annual growth rate (CAGR) of 5.2% from 2024 to 2031.

Well-known dyeing machines companies and their products on the market

There are various types of garment dyeing machine brands available on the market and different companies have different advantages about their dyeing machines. The following are 10 top Garment Dyeing Machine Manufacturers and features of their dyeing machine on the market.

TOLKAR-SMARTEX

Tolkar Garment Dyeing Machine

High speed garment dyeing machines:High liquor ratio; Less drying energy and time; Smart balance vibration’s free extraction eliminates the risk of damage; 20% less dyes; 70% less water, chemicals, steam and waste water; High speed dyeing with Spin Dye Jet Spraying Technology Prevents all crease marks, abrasion and undesired mechanical effects. Sustainable dyeing technology; Circulation and Analysis with Double Pump.

Sample dyeing machine: Remote access enables updates of parameters or versions, recipe preparation, upload/download, recipe transfer to desired machine’s USB programme and parameter transfer between machines; Automatic precision of water, chemical and steam intake in accordance with Automatic Weighing System (optional); Direct recipe transfer from sample to bulk machines without any correction.

Thies GmbH & Co. KG

Low liquor ratio has multiple cost and environmental benefits. Dye consumption is reduced up to 20 per cent while achieving the same shade, less energy is required for heating water, and the treatment of water is less costly because the Total Dissolved Solids (TDS) is reduced up to 50 per cent.

Fong’s National Engineering Co., Ltd.

Fong’s National Engineering’s Tecwin high-temperature piece dyeing machine is designed for versatility. Patented features include: a combined air and front spray nozzle to increase the degree of dye liquor exchange; an automatically controlled adjustable nozzle; a liquor dispersion storage chamber designed for improved liquor dispersion; an upper overflow to maintain pump operation with a low water level to prevent disturbance when rinsing at a high water level; and lower overflow adopted for conventional overflow rinsing.

Brazzoli S.p.A.

Rope fabric dyeing machine controls and automatically operates all the machine parameters (lap time, bath ratio, fabric absorption, pump speed, reel speed) as well as the dyeing phases; The automatic control and management system of the washing process keeps the water consumption ratio at the lowest possible level; Woven and knitted fabrics dyeing machine’s nozzles provide a perfect mixture of air and water; Eco-aero reduces water consumption and increases the quality of dyeing at the same time. Less steam consumption due to being heated less water during the process; The dyeing machine for samples and/or for small batches is bathflow which makes the product as uniform and homogeneous as possible; And the machine for delicate, light and heavy fabrics with adjustable turbovary, without tension, rotation and torsion.

Tonello S.r.l.

Sampling dyeing machine allows transferring the recipes directly with the same liquor ratio and the same mechanical action; Equipped with a low or medium-speed spin-cycle (LD3/MD3) and can be equipped with the UP system that substantially reduces the liquor ratio (LR 3:1).

High tempreture dyeing machine for sampling allows transferring the recipes directly with the same liquor ratio; Equipped with a spin-cycle appropriate for synthetic and mixed materials, it is also available in the UP version, which allows for a substantial reduction of the liquor ratio (LR 3:1).

Dilmenler Textile Machinery Co.

The continuous dyeing machine DMS03 is totally different to other dyeing machines and systems. Fabric transportation is by a mixture of air and steam and is ensured without dye bath; Dyeing process is carried out in a gas medium, where dyestuff, chemicals and auxiliaries are directly injected in an air-stream medium; The exhaust rate of the bath is very high, so that the waste water is clear and with a small residual amount of products.

Textile dyeing machine DMS04 inside/outside and outside/inside two way flow without changing the direction of the turbo pump motor; Short and fast heating times by efficient heat exchanger. DMS23’s dye bath pressure and quantity can be adjusted according to the respective fabric processed by the regulation unit. The pump builds the static pressure, which can be adjusted and controlled continuously and that pressure remains constant throughout the dyeing at all temperatures.

Morrison Textile Machinery Co.

Morrison’s Spectrum™ dye boxes with proven performance can be arranged with heating coils and jackets for wash/dye applications. FIS offers adjustable dwell lengths to increase flexibility and reduce start-up time for short set lengths. Spectrum 250 Indigo dye range with features to change sets faster with its new mix/feed configuration; Specific refinements to run lighter tensions facilitate running finer yarns never before possible in a rope range.

Sclavos S.A.

This company mainly three kinds of dyeing machine: high temperature Fabric Dyeing Machine, knitted and woven fabric dyeing machine and heavy fabric dyeing machine.

Heavy fabric dyeing machine with Aquachron FLX Continuous Washing System for nonstop operation; Integrated Control of Liquor Ratio; Low power pump built in house;

High temperature Fabric Dyeing Machine: Equipped with Soft Flow nozzle with liquor by pass ensuring gentle treatment of knitted fabrics; Operation is fully automated.

Knitted and woven fabric dyeing machine: Double Soft Floating dyeing system (DSF); Open Plaiter system with Liquor by pass; Advanced Automation system for total Interactive control and Industry 4.0 integration.

COSMOTEX

Cosmotex machines are designed to optimize dyeing treatments of readymade garments. Machines are robust and silent, designed to reduce consumption of water, energy and chemical elements, for a more sustainable, environmentally-friendly production. The constructive shape and technical features of COSMOTEX drying machines permits to control the whole drying process. Electro-welded stainless steel drum, non-water contact parts treated with special rustproof paint. It has high powerful beaters to resist heavy load volumes. Heating system can be done by STEAM, GAS or THERMAL OIL. Automatic or manual door available.

TONG GENG

The company not only has fabric dyeing machines, but also has yarn dyeing machines.

The fabric dyeing machine mainly has the following features: special designed inner plate plus large chamber structure, allowing one single nozzle to dye up to two ropes of fabric at one time. Greatly increase the production capacity (increase up to 40% and above) and reduce the cycle time required, achieving a very even color shade. Chamber is specially designed to reduce the water consumption when dyeing. The inner plate is patent designed with special w-shaped corrugated floor. Fabric flows unhindered in its circulating cycle without need of large motor pump, saving electricity cost. Liquor ratio is 1:5 ~ 7. CH Yarn dyeing machine’s pump is centrifugal type with high lifting head and large flow rate. The pump is integrated with the flow directional valve. No extra piping is required, hence lower liquid ratio; Lowest liquor ratio design; greatly reduces the requirement for water treatment, cooling water, steams, chemicals, dyestuffs and electric power. No piping required, which increase the flow efficiency.

Regional analysis of the fabric dyeing machines market

Regions that dominate the fabric dyeing machine market in 2024

According to Cognitive Market Research, North America dominated the market in 2024 and accounted for around 40% of the global revenue due to several factors. Firstly, the region boasts a mature textile industry with high demand for advanced dyeing technologies to maintain competitiveness and meet stringent regulatory standards. Secondly, technological advancements and automation in textile manufacturing drive the adoption of fabric dyeing machines, further boosting sales. Additionally, rising consumer demand for sustainable and ethically produced textiles encourages investment in eco-friendly dyeing equipment. Moreover, the presence of key market players and robust R&D activities contribute to the region’s market dominance, ensuring continuous innovation and growth.

The region with the fastest CAGR

Asia-Pacific stands out as the fastest-growing region in the fabric dyeing machines market owing to various reasons. Firstly, the region’s burgeoning population and expanding middle class are driving increased demand for textiles, boosting the need for efficient dyeing machinery. Moreover, the shift of textile manufacturing hubs to countries like China, India, Bangladesh, and Vietnam due to lower labor costs and favorable government policies further propels market growth. Additionally, technological advancements and infrastructure developments in the textile industry in Asia-Pacific countries are driving the adoption of modern dyeing equipment. Furthermore, rising investments in sustainable manufacturing practices and increasing textile exports from the region contribute to the fast-paced growth of fabric dyeing machine sales in Asia-Pacific.

Significant of dyeing machines

Dyeing machines are specialized equipment utilized in the textile industry to impart color to fabrics, yarns, and garments. Their primary purpose is to apply dyes uniformly onto textile materials, resulting in consistent coloration. These machines enable textile manufacturers to dye fabrics, enhance product aesthetics, and meet consumer preferences. By controlling various parameters such as dye concentration, temperature, and stirring, dyeing machines ensure uniform dye penetration and colorfastness, ultimately improving the quality and marketability of textile products. Overall, dyeing machines are essential tools in textile production, enabling efficient and precise color application for a wide range of materials.