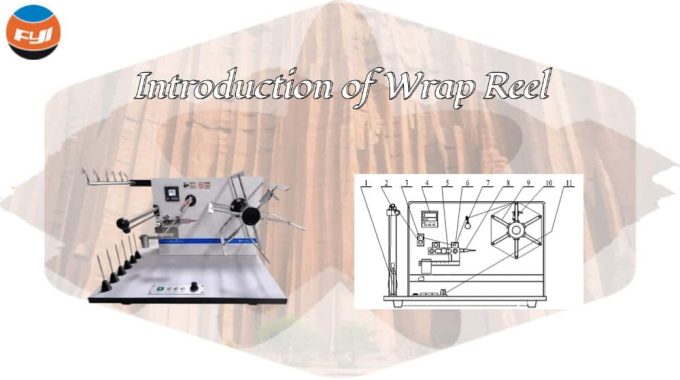

Introduction of Wrap Reel

Wrap reel is one of the instruments used to evaluate the linear density technical indicators of yarns, fibers, and filaments. Some foreign users are also use it to prepare yarn strength samples. It is widely used in the textile industries, testing institutions, quality inspection and law enforcement units and central laboratories of scientific research institutions.

The instrument controlled by a single-chip microcomputer can be set to slow down the operation 1 to 5 turns in advance of the final stop, effectively avoiding coil punching phenomenon. It can start and stop smoothly without additional tension impact, with low operating noise, accurate coil counting, good reliability, and low failure rate. The electronic counter designed as an integral part of the single-chip microcomputer has real-time speed measurement function and continuous stepless speed.

Contents

Standard

GBT 4743-2009 Textiles — Yarn from packages — Determination of linear density (mass per unit length)by the skein method

GB 8696-1988 Textiles — Yarns from packages — Method of test for breaking strength of yarn — Skein method

GB/T 6838-1986 Testing method of sewing thread

GB/T14343-2008 Testing method for linear density of man-made filament yarns

GB/T7690.1-2001 Reinforcements — Test method for yarns

Part 1: Determination of linear density

ISO6939, etc.

Principle of wrap reel

After setting the number of test turns, wrap the end of the sample around the reel through the yarn guide, tensioning device, and transverse yarn guide, start the instrument, count the rotation of the reel and display it in real time. When the reel rotates to the set number of turns, it automatically stops. When the reel starts, the CPU gives the motor a slow start instruction; before the reel stops, the CPU gives a slow rotation instruction to achieve the purpose of no punching coil, and the slow rotation speed can also be set. The biggest benefit of the reel slow start and slow stop is that it can effectively prevent the start-up breakage of low-twist yarn and weak-strength yarn, smoothly transition from start to stop, and the circle length uniformity is good.

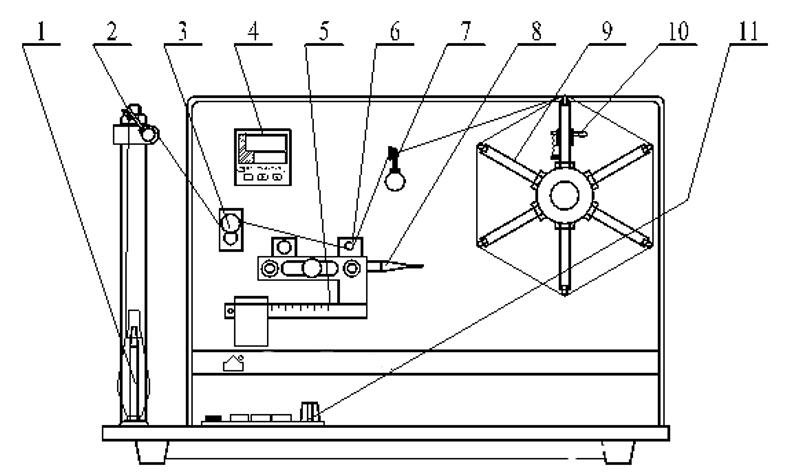

Structure

- Yarn shelf

- Guide hook

- Tensioning device

- Counter

- Little weight

- Tension detection device

- Guide hook

- Pointer

- Reel

- Handle

- Control panel

Reel

The loop length of the reel is the basis for measuring the total length of the yarn winding. The sample around the reel of the standard manufacturing reel is 1m, which means: the number of loops of the sample is the number of meters. Uniform yarn arrangement is very important, and the tension will affect the loop length. Generally, textile factory wind 100 loops (m). For the textile factories with expensive raw materials, 50 loops (m) or 20 loops (m) may be specified; if other loop length reels are customized, the user unit will calculate according to the customized loop length.

Tensioning device

The yarn length measuring instrument obtains the length of each loop of yarn taken, so the tension of the yarn affects the length. The more loops there are, the greater the difference in accumulated length. Therefore, the tensioning device is a unique technical feature in this instrument. According to the difference in the application method of pretension, the series main machine has four different appearances: YG086 mechanical tensioning device, YG086D electronic tensioning device, and YG086-10 (12) each sample has a unique tensioning device; YG086E reel is measured by “yards”; YG086J type has no tensioning device.

- The sliding code tensioning device is the tension device on the model YG086. The sliding code is positioned and fixed at a specific position according to the applied tension value. The pointer points to the marked line during the test, so it is also called a tension indicator. During the test, the pointer points to the marked line with the assistance of the tension regulator. The sliding code type of tension application method is currently the most common device. Its advantage is that the structure is intuitive and easy to understand; its disadvantage is that the use process is cumbersome, and the mechanical device will wear and rust over time. The application part of this application method requires the cooperation of a tension regulator. What is important is that the scale value on the tension scale is the individual tension value of the 6 specimens. If less than 6 specimens are tested, the scale value needs to be divided by 6 multiply the actual number of specimens equal to the actual number of tension values applied.

- The electronic tensioning device is the tension device on the model YG086D. Its advantages are simple use and easy operation; its disadvantages are slightly higher cost. This application method also requires the cooperation of the tension regulator. The application method is the same as above. The applied tension value is directly displayed on the control panel in LED mode. There is also a tension zero adjustment knob on the control panel. Before installing the sample, adjust the tension zero position to “0”.

- Spring tensioning device is the tension device on YG086-10. Most users of this tensioning method are in the chemical fiber industry. Its characteristic is that each specimen has a separate tension applying device, which rarely changes once adjusted, and the tension value is controlled by the user himself.

Traversing mechanism

The motor drives the cam to push the bar of reel to reciprocate. The bar is equipped with a yarn guide hook. The samples in the yarn guide hook are evenly and orderly arranged during the winding process of the reel. Traversing mechanism is one of the sample yarn path controllers. The reciprocating stroke of 6 samples is 35mm. The reciprocating stroke of 10 and 12 samples is 15mm. Since the bar of reel has a certain amount of movement, it is necessary to regularly apply a little butter on the contact surface between the bar and the fixed base for lubrication.

Yarn shelf

The yarn shelf is also one of the sample yarn path controllers, and the sample enters the instrument test path entrance.

Control panel

The control panel has a power switch, buttons, and speed knob, which is the hub for controlling the operation of the instrument. The control panel of the electronic tensioning device also has a tension display window and a tension zero position adjustment knob.