Testing Method for Oil Content of Man-Made Fibers

The ratio of the mass of non-volatile ester substances contained in fibers to the mass of the fiber is known as “Fiber Oil Content”.

The oil content of fibers is usually used as one of the important indicators for fiber quality evaluation, which is of great significance for the processing and application of fibers. The oil content of fibers is closely related to their spinnability. Fibers with low oil content are prone to generate static electricity, while those with high oil content are prone to sticking and entanglement, which can affect the normal operation of textile production and processing. Under the condition of meeting the requirements of anti-static and smoothness, the lower oil content of chemical fiber is better.

Contents

General Sampling Standards

- Scattered laboratory samples should be taken out as needed, and should not be less than 50g;

- The selection of the laboratory sample from short fiber batch samples shall be in accordance with GB/T14334, while the laboratory sample selection from long fiber batch samples shall be in accordance with GB/T 6502;

- Do not select packaging that is accidentally damp, contaminated, scratched, or has been opened during transportation.

Extraction Method

The methods for measuring oil content include extraction method, neutral soap washing method, refractive index method, and low field nuclear magnetic resonance method. At present, the most commonly used method is extraction method. So, we will provide a detailed introduction to the extraction method in the following.

Principle

By utilizing the properties of oil that can be dissolved in specific organic solvents, an appropriate organic solvent is extracted from the sample through a fat extractor, the solvent is evaporated, the residual oil and sample mass are weighed, and the oil content of the sample is calculated.

What you need to prepare before the experiment

Reagents and materials

- Ether – Analytical Pure

- Qualitative filter paper – oil-free

Instruments

- Fat extractor: including a condenser tube with ta height of 240 mm, an extraction cylinder with a diameter of 37mm and a length of 80mm and a distillation flask;

- Oven: can keep the temperature at 105 ℃ ± 3 ℃;

- Balance: one unit with a minimum division value of 0.1mg and 0.01g respectively;

- Thermostatic water bath pot: can be maintained at 100 ℃ at room temperature;

- Weighing container, stainless steel tweezers;

- Dryer.

Sample preparation

- Take four samples, two of which measure the oil content and the other two measure the water content.

- Measurement of oil content: Weigh 5g of each sample of short fibers, accurate to 0.01g; Combine the long fibers and twist them to ensure that each package is taken and cut evenly: weigh 7g of pre oriented and stretched fibers, accurate to 0.01g; Weigh 4g of deformed silk to the nearest 0.01g.

- Measurement of moisture content: Weigh 5g of each sample to the nearest 0.01g.

Test steps

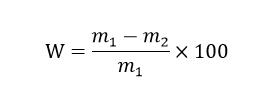

1.Determination of moisture content: Quickly place the sample into a weighing container, measure according to the GB/T6503 test steps, and calculate according to equation (1)

where:

W——moisture content of the sample, %;

m1——mass of the sample before drying, in grams (g);

m2—— mass of the sample after drying, in grams (g).

2.Place the distillation flask of the fat extractor in an oven at 105 ℃± 3 ℃ and bake it to a constant amount (i.e., the difference between the two measurements is within 0.0005g). Transfer the flask to a dryer and cool it to room temperature. Record its mass as m1, accurate to 0.1mg.

3 Weigh the mass of the sample in cubic meters, accurate to 0.1g, record it as m3. Wrap the filter paper in a cylindrical shape and place it inside the extraction tube of the fat extractor (the height of the cylinder does not exceed the highest point of the siphon). Next, connect a known mass distillation flask and inject about 1.5 times the solvent of the fat extractor’s extraction capacity into the extraction tube. Install a condenser tube.

4 Install a fat extractor on a constant temperature water bath and heat the water bath. Adjust the temperature of the constant temperature water bath and control the reflux frequency to 6-8 times per hour, with a total reflux time of no less than 2 hours.

5 Use tweezers to extract the sample from the fat extractor, squeeze out the solvent in the sample as much as possible with tweezers, remove the distillation flask, and recover the solvent.

6 Evaporate the residual solvent in the extraction bottle on a constant temperature water bath and let it dry. Place the flask in an oven and bake it to a constant amount at 105 ℃± 3 ℃. Transfer the flask to a dryer and cool for 30-45 minutes. Accurately weigh it to the nearest 0.1mg, and record it as m2.

7 Result Calculation

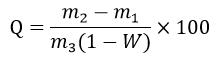

Calculate the oil content according to equation (2):

where:

Q: Oil content of the sample, %;

m1: Mass of distillation flask before extraction, in grams (g);

m2: Dry mass of distillation flask after extraction, unit: g;

m3: Mass of the sample before extraction, in grams (g).

The oil content is expressed as the arithmetic mean of two samples. When the relative difference between two parallel tests is greater than 20%, a third sample should be tested, and the test results are expressed as the arithmetic mean of the three tests.

Rapid Oil Extraction Apparatus

Our product——the Rapid Oil Extraction Apparatus YG981B does use this extraction method. It is used to determine oil or grease content of various kinds of fiber (especially suitable for wool and its blend fabric) quickly. The applicable extraction solvents are petroleum ether, ethyl ether, dichloromethane, etc.

Here is our product features:

Results can be obtained in 45~60 minutes, through simple and rapid operation;

All-metal structure, sturdy and durable;

Need a small amount of sampling: 2g of sample and 20ml of extraction solvent for one test.

Strong adaptability to environment: the instrument can be used with the 220V 50Hz power supply and an analytical balance with accuracy of 0.0001g.