Digital Bursting Strength Tester Research background and development

Digital bursting strength tester is used to determine the bursting strength and the bursting distension of textile fabrics.

Contents

Digital Bursting Strength Tester Research background

With the rapid development of market economy, the import and export trade of textile industry has increased greatly. And the testing work of fabric burst strength involved in production and new product development as well as trade process has also increased significantly. Therefore, an efficient, accurate and economical new equipment and testing method (standard) is particularly important.

As the textile materials have poor quality uniformity and large performance dispersion. Especially the woven fabrics, knitwear and non-woven products. The test of each quality index is required. And a considerable sample size is required to obtain the test results that represent the overall performance. According to the test method, the tensile strength is not suitable for some fabrics (such as knitwear and lace). But it can be replaced by the burst strength test.

Fabric tended to be at the same time by warp and weft breakage, oblique force, especially some knitwear (such as weft knitting) has the characteristics of straight to the extension, lateral contraction, straight to the lateral and influence each other, such as the tensile strength test, must be in warp and weft and oblique test respectively, and the intensity of burst can make a one-time comments on fabric strength.

Research status and development trend of electronic burst strength meter at China and abroad

In China in recent years in the textile standards, metrology and other aspects have made obvious achievements, has developed a large number of with international level close to or testing instrument.

But the air pressure burst instrument research and development, or by foreign monopoly, basically (mainly the lack of a high speed, high degree of automation devices). Although China has developed a hydraulic burst strength tester several years ago, the research and development on the aspect of pressure burst is basically at a standstill.

Electronic Bursting strength meter mainly research and development content

- The phenomenon of fabric swelling, expansion and fracture under the load of a vertical fabric plane is studied. Fabric bursting strength is an important mechanical index of fabric. Because the fabric broken often at the same time by meridional and zonal, oblique force. Especially some knitwear with straight to the characteristics of the extension, lateral contraction, straight to the lateral and influence each other, such as the tensile strength test, must to the warp and weft and oblique test respectively, and the intensity of burst can make a one-time comments on fabric strength. In theory, it can be designed by the hydraulic or pneumatic diaphragm burst principle. Hydraulic burst strength tester has been widely used in different textile industries. But there are many shortcomings that have come to light. If the use is inconvenient, not environmental protection, measurement time is long. The main purpose of our research and development is to develop a convenient, efficient, accurate and economical expanding and breaking strength testing equipment to replace time-consuming and tedious instruments.

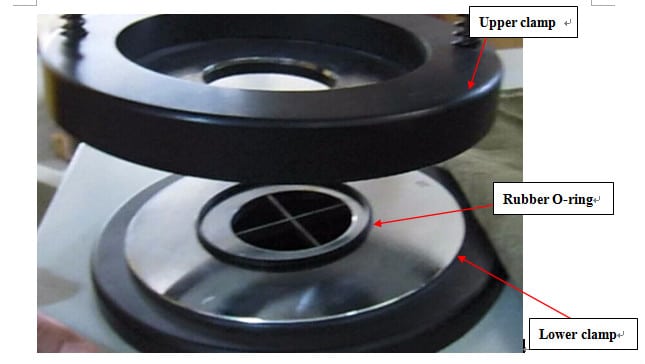

- This project requires that the measuring range is 0 ~ 1200Kpa with a resolution of 0.02Kpa. It can make the fabric burst rapidly around 20ms. But in the burst test, if the clamping head or the height of the test cup is insufficient, it will cause certain trouble. So we designed the expansion height to be up to 70mm. And we can test products with a larger expansion degree, which greatly expands its application range. More capable of testing the ever-increasing elasticity of various fabrics. Use precision mechanical design to solve or alleviate the instability of force due to too strong impact force, easy damage of sensor or diaphragm, and strong shaking of the whole machine.

- The source of electrical noise is filtered through the combination of software and hardware. In the aspect of mechanical noise, through the optimization of transmission structure and connection, the noise is further reduced. Solve the problem of data accuracy in small force high speed test.

- The actual data acquisition frequency of this instrument needs more than 2,000 times /s. We adopt 32-bit CPU to cooperate with AD with the sampling frequency greater than 200KHz. And take measures of wide channel, anti-interference and reasonable filtering to achieve the actual data acquisition frequency of 2,000 times /s.

If you need more Digital Bursting Strength Tester method and standard . please send email [email protected].