The Most Complete Guide to Color Fastness

Contents

Definition of colour fastness

The so-called color fastness refers to the degree of fading of dyed fabric under the action of external factors (extrusion, friction, washing, rain, exposure, light, seawater impregnation, saliva impregnation, water stains, sweat stains, etc.) during use or processing. It is an important index of fabric.

Color fastness refers to the resistance of the color of a textile to various effects during processing and use. The fastness grade is evaluated according to the discoloration of the sample and the stain of the undyed lining fabric. The colour fastness test of textiles is a routine item in the intrinsic quality test of textiles.

Textiles will be subjected to various external effects such as lighting, washing, ironing, sweat stains, friction and chemical agents during their use. Some printed and dyed textiles have also undergone special finishing processing, such as resin finishing, flame retardant finishing, sand washing, wool grinding, etc., which requires the color and color of printed and dyed textiles to maintain a certain fastness.

Types of color fastness

Color fastness includes colour fastness to soap washing (sample), colour fastness to rubbing, color fastness to chlorine water, color fastness to non-chlorine bleaching, color fastness to dry cleaning, color fastness to actual washing (garments, fabrics), colour fastness to sweat stains, color fastness to water, color fastness to light, colour fastness to sea water, colour fastness to saliva, etc.

Introduction to common color fastness

Color fastness to washing: The sample is stitched together with the standard lining fabric, washed, cleaned and dried, and washed at the right temperature, alkalinity, bleaching and friction conditions to obtain test results in a relatively short time. The friction action in between is completed by small bath ratio and the appropriate number of stainless steel beads rolling, impact, with gray card rating, get the test results.Different test methods have different temperature, alkalinity, bleaching and friction conditions and sample size, specific to the test standards and customer requirements to choose. General washing colour fastness is poor color green orchid, bright blue, black red, navy blue, etc.

Color fastness to dry cleaning: Same as color fastness to washing.

Rubbing colour fastness: Put the sample on the rubbing fastness tester, and rub the standard rubbing white cloth against it for a certain number of times at a certain pressure. Each group of samples shall be tested for dry and wet rubbing colour fastness.The color on a standard friction white cloth is rated by a gray card. The resulting series is the measured colour fastness. The colour fastness of friction requires both dry and wet rubbing tests, and all colors on the sample should be rubbed to.

Colour fastness to sunlight: Textiles are usually exposed to light when they are used, which can damage the dye and lead to the well-known “fading”, so that colored textiles change color, generally become lighter and darker, and some will also change color light. Therefore, it is necessary to test the color fastness. That is, the sample and blue wool standard cloth with different levels of fastness are placed together under specified conditions for solar exposure, and the sample is compared with blue wool cloth to evaluate the color fastness to light. The higher the level of blue wool standard cloth, the more light fastness.

Color fastness to perspiration: The sample is stitched together with the standard paste lining fabric, placed in the perspiration liquid, clamped on the colour fastness to perspiration, placed in the oven at constant temperature, and then dried, rated with gray card, test results. Different test methods have different perspiration liquid ratio, different sample size, different test temperature and time.

Colour fastness to water stains: Test samples treated with water as above.

Chlorine bleaching fastness: After the fabric is washed in chlorine bleaching solution under certain conditions, the degree of color change is assessed. This is chlorine bleaching fastness.

Non-chlorine bleaching fastness: After the fabric is washed in the washing condition with non-chlorine bleaching, the degree of color change is assessed. This is the non-chlorine bleaching fastness.

Pressing color fastness: After the dry sample is covered with cotton lining fabric, it is pressed in the heating device of specified temperature and pressure for a certain period of time, and then the color change of the sample and the colour touch of the lining fabric are evaluated with a gray sample card. The colour fastness of hot pressing includes dry pressing, damp pressing and wet pressing. The test method should be selected according to different customer requirements and test standards.

Color fastness to saliva: the sample and the specified lining fabric are bonded together, placed in artificial saliva for treatment, the test liquid is removed, placed between two plates in the test device and the specified pressure is applied, and then the sample and the lining fabric are dried respectively, and the color change of the sample and the stain of the lining fabric are evaluated with gray card.

The importance of color fastness

Good or poor color fastness is directly related to human health and safety. When products with poor colour fastness encounter rain or sweat during wearing, the pigments on the fabric will fall off and fade, and the dye molecules and heavy metal ions may be absorbed by the skin and harm the health of human skin. On the other hand, it will affect the coloring of other clothes worn on the body. Or stain other clothes when washing with other clothes.

Due to the great difference in the processing and use of fabrics, the requirements are different, so most of the current test methods are based on the environment and conditions of the simulation test or comprehensive test, so the test methods of color fastness are quite extensive. However, throughout the International Standards Organization (ISO), American Society of Dyers and Chemists (AATCC), Japanese (JIS), British (BS) and many other standards, the most commonly used are washing resistance, light resistance, friction and sweat resistance, ironing resistance, weather resistance and so on. In practice, the test items are mainly determined according to the end use and product standards of the products. For example, wool textile product standards specify that the colour fastness to sun exposure must be tested, knitted underwear must be tested for sweat stain fastness, and outdoor textiles (such as sunshade, light box cloth, canopy material) must be tested for colour fastness to weather.

Test of colour fastness

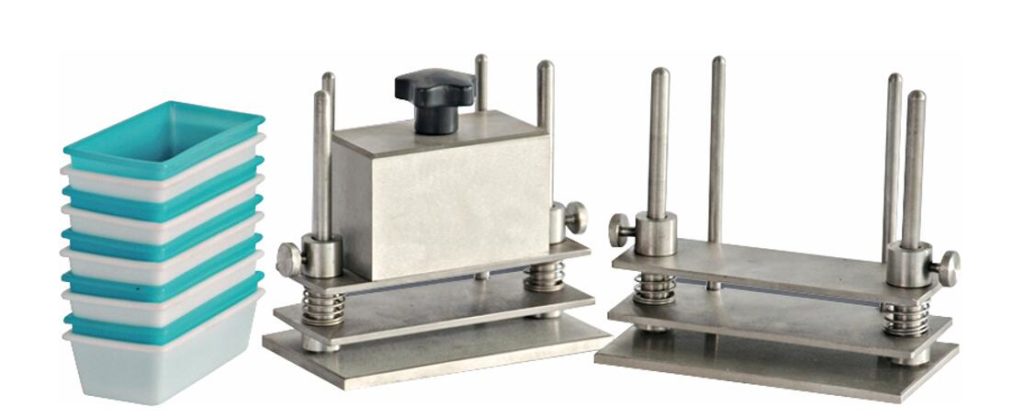

Perspiration Color Fastness

YG631 Series Perspiration Color Fastness Tester

Application: YG631 Series Perspiration Color Fastness Tester is used to determine color fastness to water, perspiration, saliva and seawater of textiles.

Related Standards: ISO105 E01, E02, E04, AATCC15, 106, 107, 165, GB/T 3922, 5713, 5714, JIS L0846, L0847, L0848, etc.

Feature:

- Special designed weight sets satisfy various requirements of ISO and/or AATCC standards;

- Micro-computer with PID parameters controlling function, avoid temperature overshoot;

- Adopt advanced design of blast system, and the temperature fluctuation is low, Temperature uniformity is stable;

- Heater is controlled by contactless solid state relay, no noise, long service life;

- Oven temperature and time are pre-settable with temperature duly displayed;

- Digital timer with audible alarm when the preset time is over;

- The working chamber is made of 304 mirror-like stainless steel plate, effectively prevent acid and alkali corrosion;

- With two layers of stainless steel shelf, each layer can be placed two test frames, there are max. four test frames for each test, it surely saves energy and improve work efficiency;

- The door has a large size of double tempered glass observation window.

Y902 Oven for Perspiration Colour Fastness Test

Application: Y902 Oven for Perspiration Color Fastness Test is used with YG631 series perspiration color fastness tester together to carry out the color fastness to perspiration test.

Related Standards: ISO105 X16, AATCC16, etc.

Rubbing colour fastness

Y571A Series Rotary Crockmeter

Application: Y571A Series Rotary Crockmeter is used to determine the color fastness of textiles to dry and wet rubbing, particularly for printer fabrics.

Related Standards: ISO105 X16, AATCC16, etc.

Feature:

- Stainless steel structure, durable and easy to clean;

- Turn the manual handle to drive the reciprocating rotary motion of the vertical weighted rod. The manual handle is turned in one direction only;

- Compact and space-saving.

Y571J Color Fastness/Rubbing (Gaskushin) Tester

Application: Y571J Color Fastness/Rubbing (Gaskushin) Tester is used to determine the color fastness of textiles to rubbing, and provided with a moving platen with a downward force of 2 Newton. It is electronically driven to minimize operator variation.

Related Standards: JIS L0801,0849, etc.

Feature:

- Each working station is equipped with a removable rubbing head and a set of clamp to allow up to six specimens tested simultaneously;

- With inching speed control;

- Protective cover protects operators’ hands from injury;

- Simple operation, equipped with preset function, the machine will stop automatically when the preset number is over.

Y571 Series Crock Meter/Rubbing Fastness Tester

Application: Y571Series Crock Meter/Rubbing Fastness Tester is used to determine the colour fastness of textiles and leather to rubbing under either dry or wet condition.

Related Standards: ISO105 D02, 105 X12, AATCC8,165, etc.

Feature:

- Motor-driven to minimize operator error and improve efficiency

- Using preset LED digital display counter, can set test times arbitrarily;

- Specimen clamp ensures rapid specimen mounting and prevents slippage;

- Two different sizes of rubbing heads can be used to meet different standards;

- The rubbing platform is treated with electroplating chromium to prevent rust;

- The roller of small wringer is made of brass and is durable.

Sublimation colour fastness

YG605 Series Scorch/Sublimation Tester

Application: YG605 Series Scorch/Sublimation Tester is used to determine color fastness of fabrics to hot pressing or dry heat and to conduct sublimation test.

Related Standards: AATCC 114, 117, 133, ISO 105-P01, 105-X11, JIS L0850, L0879, etc.

Feature:

- Equipped with MCU to control time and temperature, and over-temperature safety function to shut down the unit in case of over-heating;

- High quality temperature sensor (PT100), more accurate to control temperature and more endurable;

- Two separate heating coils for top or bottom hot plate can be individually operated under relative standards;

- Temperature of 3 group heating blocks is separately controlled (For YG605-III).

YG607D Hot Flat Ironing Tester

Application: YG607D Hot Flat Ironing Tester is used to determine the stability and durability of fabrics to hot pressing.

Related Standards: ISO 9866, etc.

Feature:

- Test pressure adjustable;

- Uniform heating;

- Temperature and time display by LED.

Color Fastness to Washing

SW Series Colour Fastness to Washing Tester

Application: SW Series Color Fastness to Washing Tester is used to determine the color fastness to washing or dry cleaning of fabrics consisting of cotton, wool, silk, ramie, chemical fiber, etc. and it is also used to examine the dye washing color fastness capability for dyeing industries, textiles inspection departments and research departments, etc.

Related Standards: ISO 105-C01~C05, ISO105 D01, GB/T 3921.1~5, 5711, BS1006, AATCC 61(1A-5A), 132, IWS TM177, 193, etc.

Feature:

- Touch screen, easy to operate;

- Low water level protection, the heating is not accessible if do not reach minimum water level;

- Relative standards have been built in the program, select the corresponding standard to proceed the running directly;

- Custom standards, define the standard by oneself, e.g. temperature, time;

- Fitted with over temperature protection device to shut down the unit in case of overheating.

Colour fastness to sunlight

FY3600+ Water-cooled Weather Conditions Meter

Application: Water-cooled Weather Conditions Meter. To determine the color fastness and aging to sunlight, weather resistance, compound color fastness to sunlight-sweat of colored textile, leather, leatheroid, plastic, etc, by setting various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. Be able to control irradiance real-time, automatically inspect and compensate irradiance, temperature, humidity.

Feature:

- Presetting various specifications, or customized programs, meet diverse range of standards,including AATCC, ISO, BS, JIS etc;

- Touch screen, and build-in PLC, real-time display the ongoing test’s graph, be able to presetting irradiance, temperature, humidity, and plot dynamic curve of them.

- 4500W water-cooled xenon arc lamp system, accurately simulate sunlight spectrum. Irradiance auto-compensates system, control irradiance, temperature, and humidity timely through a closed loop.

- Irradiation control, light irradiance sensor monitor, digital setting, automatic compensating system, stepless irradiation regulation.

- Accurate chamber temperature control, irradiation temperature, and heater raise the temperature, air conditioning refrigeration system.

YG611M Air-Cooled Xenon Arc Tester

Application: YG611M Air-Cooled Xenon Arc Tester is used to determine the color fastness and aging to sunlight, weather resistance, compound color fastness to sunlight-perspiration of colored textile, leather, plastic, etc., by setting various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. Be able to control irradiance real-time, automatically inspect and compensate irradiance, temperature and humidity.

Feature:

- 10.4 inch color touch screen display, Windows operation system, brief control interface, few setting procedures and simple operation;

- Real-Time graphic display, the operator can easily get access to the test process;

- Independent controlling of each sample to test, samples’ test time is controlled separately, set the time for each specimen and when the set time is over, the corresponding specimen can be taken out and continue the test of remaining specimens; automatic reminding when each specimen’s test is over.

BZGY908 Series Color Assessment Cabinet

Application: BZGY908 Series Color Assessment Cabinet is a universal preferred choice for colour fastness, close and accurate color matching of textiles in dyeing and garment industry.

Feature:

- Use PhilipsTM and GETM lamps, PhilipsTM bulb (F light source). The lifetime of each lamp up to 4000h (recommended max operation time: 2000h for more accurate test result).

- Use RamtronTM memory, with individual lighting lifetime record function and operating times record function (by on/off) (see figures in page above).

- Manual sequence lighting function. Operators can make any combination from existing lights by easily pressing corresponding button of lights.

- With energy-save function, auto power off when reach 2 hours without any operation.

- Optional 45°fixed angle viewing plate makes assessment process more comfortable and comparable.

- Available light source.

Gray Scale for Color Change

Application: Gray Scale for Color Change is suitable for visually evaluating changes in color of textiles resulting from colorfastness tests.

Related Standards: ISO 105-A02; GB/T 250; AATCC EP1

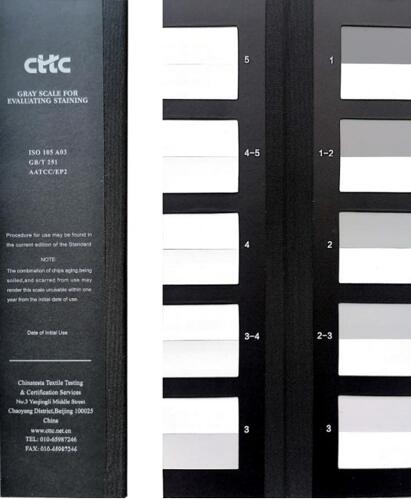

Gray Scale for Staining

Application: Gray Scale for Staining is suitable for visually evaluating staining of textiles resulting from colorfastness tests.

Related Standards: ISO 105-A03; GB/T 251; AATCC EP2

Leave a Reply

You must be logged in to post a comment.

Hi, just wanted to say, I liked this article. It was inspiring. Keep on posting!

This is such a admirable post. Really appreciated and amazing. Keep sharing more post.

Thank you for another great article. Where else could anyone get that kind of information in such a perfect way of presentation

Excellent blog here! Also your site loads up very fast! What host are you using? Can I get your affiliate backlink to your host?