Warp knitting machine and weft knitting machine

We can usually distinguish warp knitting machines from weft knitting machines by the type of fabric that the machine produced. The wrap knitting machine produces wrap fabrics, and the other produces weft fabrics.

Contents

What is wrap knitting machine

The warp knitting machine includes following mechanism: braiding structure, comb bar traverse mechanism, let-off mechanism, pulling and coiling mechanism and driving mechanism.

The main loop forming parts of warp knitting machine are knitting needles, yarn guide needles, sinkers and pressure plate (used for crochet machine). The knitting needles are arranged in a row on a needle bed and move with it. Guide needles are mounted on strips. Stripping comb consists of a guide needle mounted on a strip. The warp yarn passes through the hole of the guide needle, moves with the stripping comb and pads on the needle. Through the mutual movement of the knitting needle, the sinkers and other circular machine parts. Then the wrap yarn can be knitted into the fabric.

We often use warp knitting machine to knit curtain, tablecloth, bedspread, blanket, lace, women’s inner coat, fishing net, packaging bags and other complex warp knitting fabrics.

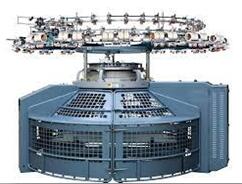

What is weft knitting machine

General structure of weft knitting machine:

- Yarn feeding mechanism: The yarn feeding mechanism has another name, feeding mechanism. It include yarn frame, yarn storage device (weft storage), feeding mouth, feeding plate, yarn ring bracket and other components.

- Knitting mechanism: We can also call the loop forming mechanism the knitting mechanism, and its main parts are syringes, knitting needles, sinkers, triangular device and yarn guide device, etc. These parts cooperate with each other to form the loop movement.

- Pulling and coiling structure: The function of the pulling and coiling structure is to pull the machine knitted fabric out of the knitting area and wind (or fold) it into a certain coil form.

- The driving mechanism: The driving mechanism is the mechanism that makes all parts of the machine move.

- Auxiliary mechanism: The auxiliary device helps us to ensure the normal operation of knitting. Auxiliary devices of weft knitting machine usually include not only fault stop device, brake device, automatic refueling device. But also cleaning and dust removal device, cloth expander, switch device and so on.

Weft knitted fabric not only has soft texture, good crease resistance and air permeability. But also has greater extensibility and elasticity, suitable for underwear, tights and sportswear.

Difference between wrap and weft knitting machine

The elongation of the fabric

Warp knitting has limited elongation, usually a little in the transverse direction and almost no in the longitudinal direction. Weft knitting has good elongation in both the longitudinal and transverse directions.

Fabric disassembly

Warp knitting fabric doesn’t come apart easily. On the contrary, weft knitting fabric comes apart easily.

The efficiency of production

Warp knitting machine can only knit flat fabrics and semi-finished products. Weft knitting machine can produce flat and cylindrical fabric rolls, where we can use it for garments, garment pieces and formed fabrics.

Production

Warp knitting machine can only be produced in batches. However, for the other machine, we only use it in small batches.

Intuitive difference

Front and back lines are the same is weft knitting fabric, vertical is warp knitting fabric.

Our company produces two kinds of knitting machine:DW0910 and DW0910S. Both of them are belong to weft knitting machine. For more information about these, please send email to [email protected].

Comments are closed.

The post is really a helpful interesting and well-written details. The a lot more Someone said the more I want to study. Any article writer that makes the time and effort to publish participating articles similar to this needs to be commended.

Awesome! I learned a lot. Thanks so much, keep posting more.

This post is worth for me.