Guide to Rotor Spinning Machine

Contents

- 1 What is the principle of rotor spinning machine?

- 2 What is rotor spinning machine?

- 3 What is the rotor spinning process?

- 4 What is the difference between ring spinning and rotor spinning?

- 5 What are the advantages of rotor spinning?

- 6 What are the disadvantages of rotor spinning machine?

- 7 DW7042H Lab Rotor Spinning Machine

What is the principle of rotor spinning machine?

Rotor spinning is a new spinning technology which uses air flow to condense and twist fibers in a spinning cup with high speed rotation. He does not use spindle, mainly rely on comb roller, spinning cup, false twist device and other parts. The carding roller is used to grab and comb the feed of the cotton strip fiber, through the centrifugal force generated by its high-speed rotation can throw out the grabbed fiber. The spinning cup is a small metal cup that spins more than 10 times faster than the comb roller. The resulting centrifugal action pushes the rotor out of the cup. According to the principle of fluid pressure, make the cotton fiber into the rotor cup, and form the fiber flow, along the inner wall of the cup constantly movement.

What is rotor spinning machine?

Unlike ring spinning, rotor spinning does not use spindle twisting, winding and forming. It mainly relies on several parts such as carding roller, spinning cup and false twisting device. The carding roller is used to grab and comb the feed fiber, and the centrifugal force generated by its high-speed rotation can throw out the grabbed fiber. The spinning cup is a small metal cup that spins more than 10 times faster than the comb roller. The resulting centrifugal action pushes the rotor out of the cup. According to the principle of fluid pressure, make the cotton fiber into the rotorflow cup, and form the fiber flow, along the inner wall of the cup constantly movement. At this time, there is a yarn head outside the cup, which leads out the fibers of the inner wall of the cup and connects them together. Coupled with the centrifugal effect caused by the high-speed rotation of the yarn tail of the cup, it is like “feeding” the cotton fibers while twisting the yarn, so that the yarn is connected with the fibers of the inner wall of the cup. Under the rotating tension of the yarn barrel, the yarn is wound continuously, and the process of rotor spinning is completed.

Characteristics of rotor spinning:

1. High speed

2. Large roll

3. Short process, reduce investment in infrastructure and equipment

4. Simple mechanism and no spindle, steel collar, wire ring

5. Compared with ring spinning, it can increase the yield exponentially

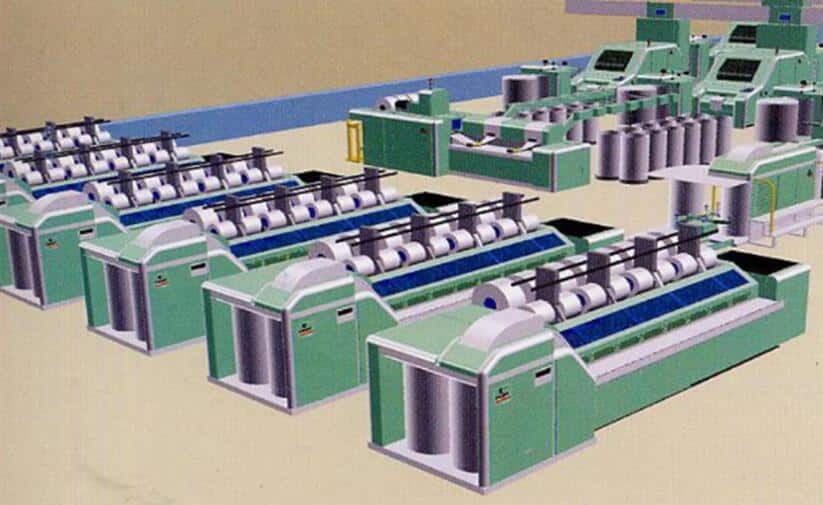

What is the rotor spinning process?

Rotor spinning process: cleaning — carding cotton — strip– rotor spinning

1. The role of the cleaning process

- Loosening – decomposing the raw material from a compact state to a relaxed state.

- Mixing – The mixing of multiple or multicomponent ingredients evenly.

- Decontamination — To remove impurities from raw materials as much as possible.

- Carding – try to separate the fibers into a single fiber state.

- Strip – as required to be packed in strips in a tampon bucket for the next process.

2. The role of combing process

- Further remove impurities, especially fine impurities;

- Try to remove short fibers (short velvet) and cotton knots;

- Further mixing;

- Further carding and stretching to improve the straightenness of the fibers;

- In accordance with the requirements of the strip dressed in the cotton bucket, for the next process of production.

3. The function of the parallel process

- Evenness – to improve the evenness of the strips of cotton so as to obtain more uniform yarn;

- Parallel – to make the fibers in the sliver more straight and parallel;

- Blending – To mix fibers as required;

- Strip – as required to be packed in strips in a tampon bucket for the next process.

4. The role of roving process

- To thin a strip of cotton;

- Straighten the fiber further;

- Add a twist;

- Winding forming, convenient for the next process production.

5. The function of the spinning process

Drawing the roving to the desired count by drawing;

By twisting the yarn to get enough strength, so that the yarn can meet the requirements of a certain style or feel of the fabric;

Winding forming, convenient for the next process production.

What is the difference between ring spinning and rotor spinning?

Ring spinning is the most widely used spinning method in the market. It refers to the drawn fiber strip of sliver or roving yarn in the previous spinning process, which is rotated and twisted through the ingot steel wire ring in the spinning process. The bobbin winding speed is faster than the steel wire ring, and the fiber is twisted into spinning yarn. It is widely used in all kinds of short fiber spinning system engineering, such as common combing, combing and blending.

Features:

1. The steel wire ring is driven by the bobbin through the yarn strip around the steel lead. For twisting,

2. The friction of the steel collar makes its speed slightly less than that of the bobbin, resulting in winding, so the spinning speed is high.

3. The shape of ring spinning is that the fibers are mostly conical spiral lines transferred inside and outside, so that the fibers are wound and connected inside and outside the yarn, and the structure of the yarn is tight and the strength is high.

4, Suitable for thread making, knitting and other products.

Rotor spinning and ring spinning are new textile technology and old spinning technology. It is twisted by spindle, steel bell and steel ring, and drawn by roller. rotor spinning, on the other hand, is carried by rotor flow, and twisted by one end. Generally speaking, ring spun yarn has more hrotoriness, higher strength and better quality than rotor spun yarn. The rotor spinning process is short, the protruding hrotor is less, especially the viscose fiber is more obvious, the fiber on the yarn will not break, but many hrotor is wrapped in the yarn body, so the spinning cup yarn hrotor is less, the count and twist can not be very high, and the price is low.

In terms of yarn structure, ring spinning is more compact, while rotor spinning is fluffy and rough, suitable for denim fabric, rotor spinning yarn is generally thicker.

1. Ring spinning and rotor spinning, one is the traditional textile technology, with a history of nearly 200 years, the other is the new spinning technology, with a history of 50 or 60 years.

2. Ring spinning is mechanical spinning, which is drawn by roller, twisted and wound by spindle, steel collar and steel wire ring. rotor spinning is made by spinning cup running at high speed to produce vacuum, and the fiber is transported by rotor filling, which is held by one end and twisted.

3. Generally speaking, ring spinning is suitable for better raw materials, less hrotor, higher strength and better quality. The rotor flow spinning process is short, the raw material is short, the yarn wool, the number and twist can not be very high, and the price is low.

4. From the perspective of yarn structure, the yarn spun by ring ingot is tight and soft, suitable for underwear fabric, etc., while the fluffier yarn with rough style is suitable for denim fabric.

What are the advantages of rotor spinning?

The advantages of pure cotton rotor spinning:

1. The strips of rotor-spun yarn are good and even, with less impurity and yarn defects.

2. Rotor spinning yarn has high anti-wear strength and is not easy to pilling compared with ordinary ring spinning process.

3. The yarn has many twist, large tension and good elasticity.

4, Rotor spinning yarn structure fluffy, strong hydrophilicity, soft yarn, dyeing and hygroscopicity is better.

What are the disadvantages of rotor spinning machine?

Poor tube yarn forming, poor yarn drying, slub yarn, broken end height, uneven strength and other problems.

DW7042H Lab Rotor Spinning Machine

DW7042H Lab Rotor Spinning Machine is used to produce open-end yarn by rotor spinning.

FEATURES:

Delta PLC + touch screen, easy to learn and operate;

Carding, spinning and Twist drive independently;

Multi function design ,easy to clean, set and maintain;

KEY SPECIFICATION:

| Applicable fiber length | 20~50mm |

| Control mode | PLC & touch screen |

| Spindle number | 1 or specify |

| Rotor speed | 30,000rpm |

| Carding roller speed | 6,000rpm |

| Coiling speed | 20~110m/min |

| Draft range | 30~250 |

| Power supply | AC220V, 50Hz |

Comments are closed.

The post has a way of making even the most mundane topics seem fascinating.

I love how you’re able to inject your own personality and voice into every blog post. It really adds a human element.

This is exactly the kind of content that the internet needs more of – informative, thought-provoking, and engaging.

How you manage to maintain a consistent level of quality in your blog posts is truly inspiring.

Which blogging platform you use is worth considering, as your posts display excellent formatting and readability.

When it comes to captivating content, this blog never disappoints. How the author effortlessly blends storytelling with factual information is truly impressive. Each article is a testament to their impeccable writing skills and their ability to engage readers from start to finish.

Who would have thought that a blog could elevate your thinking to new heights? This one does exactly that. The author’s insightful perspectives and well-reasoned arguments challenge readers to expand their viewpoints and consider alternative interpretations.