Ultra Complete Guide to Fiber Fineness

Fiber fineness refers to the thickness of the fiber. Fineness is one of the important morphological dimensions and quality indicators of fibers. Fiber fineness is closely related to spinning process and yarn quality, and directly affects fabric style.

Contents

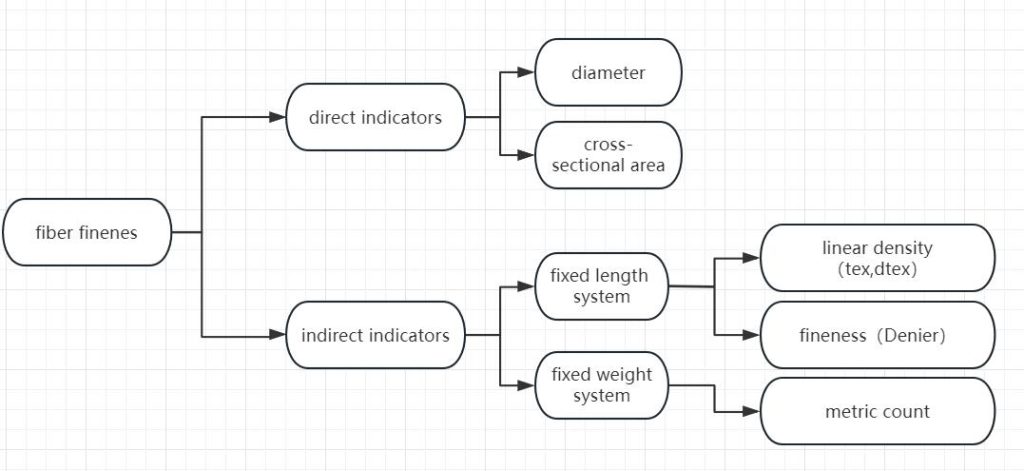

Fiber fineness index and its conversion

Direct indicator

It is expressed directly by the geometry index of the fiber. Such as diameter (d), projected width, cross-sectional area, cross-sectional perimeter, specific surface area, etc.

Fiber diameter was observed by optical microscope or electron microscope. It can be used to characterize the fineness of wool and its animal hair, and round chemical fibers.

Indirect indicators

Expressed indirectly by the relationship between fiber length and mass

Gk–the weight of the fiber at the specified moisture regain (g)

L–fiber length (m).

1. Linear density: Tex (Nt), decitex (Ndt)

Tex: The mass in grams of a 1000-meter-long fiber at a given moisture regain.

dtex: The mass in grams of a 10,000-meter-long fiber at a given moisture regain.

Nt =Gk/L×1000

Ndt =Gk/L×10000

2.Denier (Nd): The mass in grams of a 9,000-meter-long fiber at a given moisture regain.

Nd = Gk/L×9000

3. Metric count Nm: The length (mm or m) of fiber per unit mass (mg or g) at a given moisture regain. (The English count Ne is generally used to characterize the yarn fineness)

Nm = L/Gk

4. Micronaire value (M): As a dimensionless value, it is measured by a Micronaire airflow meter and reflects the comprehensive index of cotton fiber fineness and maturity. Divided into 3 levels, namely A, B, C level. The B grade is the standard grade.

Conversion between indicators:

Nt ×Nm = 1000

Nm ×Ndt = 9000

Nd =9 Nt

Fiber fineness test method

1. Direct measurement method: microscope method, fiber projection measurement method, laser fineness test method, computer image automatic measurement method

Quantitative method, etc.

2. Indirect measurement method: mid-section weighing method, air flow method, vibration method, etc.

Microscopy is commonly used to measure the fineness of wool and the longitudinal projected diameter of fibers with round cross-sections.

The airflow method is often used to indirectly measure the fineness of cotton fibers, wool fibers and chemical fibers.

The mid-section method can be used to measure the fineness of various fibers, but for crimped fibers, the crimp can only be measured accurately, and it is generally used for cotton fibers or non-crimped chemical fiber filaments.

Fiber fineness tester

JN-B Series Torsion Balance

The JN-B Series Torsion Balance is a delicate, precision measuring tool used for weighing tiny things. It is applicable in the sectors of electronics, textiles, metallurgy, agriculture, industry, and others.

Y171 Series Fiber Cutter

Fiber Cutter is intended to cut fiber, yarn, cotton, and other materials into cross-sectional slices for examination under a microscope.

Y175 Series Cotton Fineness Meter/Micronaire Tester

The Y175 Series Cotton Fineness Meter/Micronaire Tester is used to determine the micronaire value of cotton fiber. Weigh out a test specimen of proper mass for the airflow instrument (8g) using the balance; pack the test specimen evenly into the compression cylinder, then insert the compression plunger. Using the air pump or any acceptable method, force air through the specimen at the appropriate pressure for the air flow instrument and record the reading on the scale.

YG002C Series Computerized Fiber Fineness Analysis System

The YG002C Series Computerized Fiber Fineness Analysis System is used in labs to quickly evaluate fiber diameter or sectional area. The gadget uses a high-resolution industrial camera to connect an optical microscope and a computer. Professional analysis software can do fiber diameter and sectional area testing, as well as assess the content of each fiber in blended fiber.

Y172 Fiber Microtome(Hardy)

Microtome for fiber (Hardy). To make fiber cross sections with thicknesses ranging from 20um to 100um for microscopic observation, measurement, and identification.

ZK100F Fiber Fineness Tester (Vibroscope Method)

The ZK100F Fiber Fineness Tester (Vibroscope Method) may be used to determine the linear density of a single fiber using the vibroscope method. It is widely utilized in chemical fiber, textile, and other manufacturing companies, testing organizations, and scientific research units.

The main working idea is to compute and show the linear density of a single fiber based on its natural vibration frequency under certain vibration length and stress.

Y145A /B Wool Fineness Meter

The Y145A Wool Fineness Meter is used to measure the fineness of wool fiber by micronaire value, which is determined by the value of air resistance of disordered wool fiber. The Y145B Wool Fineness Tester is extensively used in wool purchase inspection, production, and commerce to assess the fineness of wool using the airflow technique.

Effect of fiber fineness on fibers, yarns and fabrics

Uneven fineness will lead to uneven yarn and yarn defects, but on the other hand, having a certain different linear density is beneficial to the formation of certain qualities of yarn.

To the fiber itself

- The thickness of the fiber will affect its specific surface area, adsorption performance and dyeing properties of the fiber.

- The fiber becomes thicker, so that the bending stiffness of the fiber increases, the point contact area increases, and the fiber becomes rigid and feels sticky and cold.

- Uneven fineness between fibers will cause differences in fiber mechanical properties.

- Differences in fineness within the fiber can lead to mechanical weakness of the fiber.

Effect on yarn quality and spinning process

Relationship with yarn strength:

Under other conditions being the same, the finer the fiber, the higher the yarn strength.

Relationship with yarn evenness:

Under other conditions being the same, the finer the fiber, the more even the yarn will be;

Under the premise of ensuring the quality of the yarn, fine and uniform fibers can be spun into finer yarns.

Relationship to the spinning process:

The finer the fiber, the easier it is to kink and break during processing to produce neps and short fibers.

Effect on fabric

Fibers of different fineness will greatly affect the feel and performance of the fabric. For example, underwear fabrics require softness and comfort, and finer fibers can be used; outerwear fabrics require stiffer fibers, and generally thicker fibers can be used.

The relationship between fiber fineness and function

| Fiber fineness type | Linear density (dtex) | Diameter (mm) | performance characteristics |

| Linear density (silk type) | 1.1~2.8 | 4~10 | soft, smooth, thin |

| cotton, silk fiber | 0.89~1.33 | 8.41~13.7 | soft, even, thin |

| Wool and hemp fiber | 1.1~2.2 | 13.7~17.7 | soft, even, thin |

| Microfiber | 0.011~0.89 | 3.0~11.0 | Moisture absorption, moisture conduction, delicate, imitation leather |

| Leather (extra fine) | 0.011~0.11 | 0.9~4.0 | Vapor-permeable, waterproof, fine, suede features |

| Microfiber | 0.0001~0.01 | 0.09~0.12 | Adsorption, ultrafiltration, function |

| Nanofibers | 1e-8~1e-4 | 0.001~0.1 | special function |

Comments are closed.

So glad I stumbled upon this blog. The quality of writing is top-notch.

More real-life examples and personal anecdotes would have enhanced the readers’ connection to the blog topic.

Hey, fellow readers! I stumbled upon this blog and it’s worth sharing with all of you.