A Comprehensive Guide to Color Fastness to Light

Last update: May 23, 2025

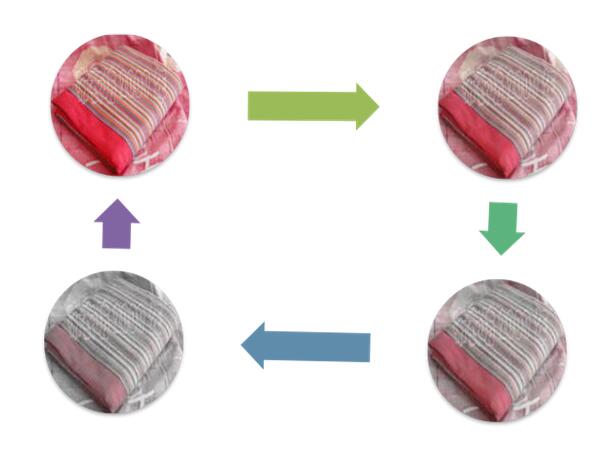

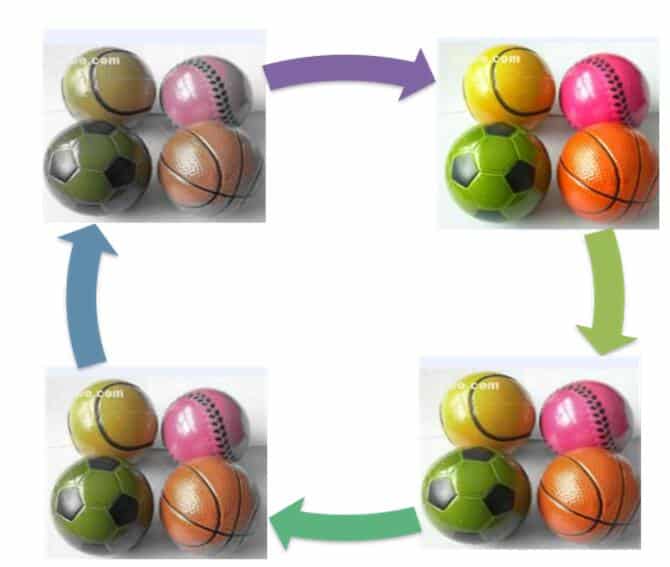

Color fastness to light is to measure the solar resistance of dyes and materials. The test method can be either sun exposure or solar machine exposure. The fading degree of the sample after sun exposure is compared with the standard color sample.

Under artificial conditions, accelerate the simulation of various textiles, clothing, dyes, plastics, rubber, plastics, automotive interior parts, geosynthetic and other materials often exposed to natural climate conditions due to the sun, rain, temperature, humidity, alternating light and shade after the comprehensive effect of its physical and chemical properties (also known as aging) test.

Contents

Factors affecting color fastness to light

Effect of dye concentration on color fastness to light:

The color fastness of cotton fabric is related to the variety of dye. The lower the dye concentration, the worse the color fastness.

The influence of pH value of fabric on color fastness to light:

pH value has a great influence on the sun fastness of cotton fabric. The color fastness of cotton fabric near neutral is the best. The color fastness of cotton fabric is not good for acid or alkaline.

Effect of moisture content of fabric on color fastness to light:

The moisture content has great influence on the color fastness of cotton fabric. The higher the moisture content, the worse the color fastness. This is mainly because the larger the moisture content of cotton fabric, the larger the area of the dye particles gathered on the surface of the fabric and the water, the lower the color fastness to light.

The influence of light fastness accelerator on sun fastness:

Sun fastness accelerators are effective for improving the sun fastness of cotton fabrics and should be used together with other finishing procedures. Therefore, attention should be paid to the synergistic and reducing effects of sun fastness accelerators and other reagents when finishing cotton fabrics.

We also analyzed the influencing factors of color fastness to light from some other perspectives.

Which industries use on the light fastness test

Textiles

Clothing

Dyes

Plastics

Rubber

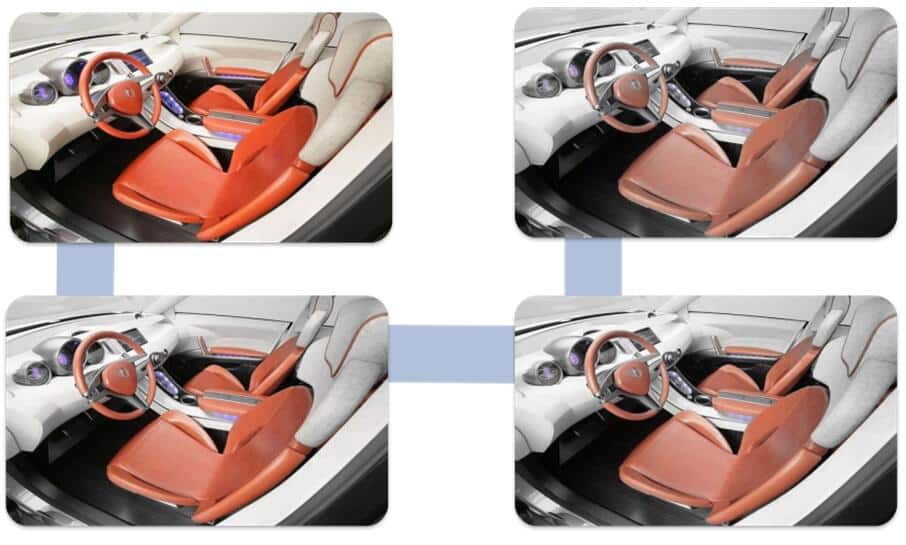

Automotive interiors

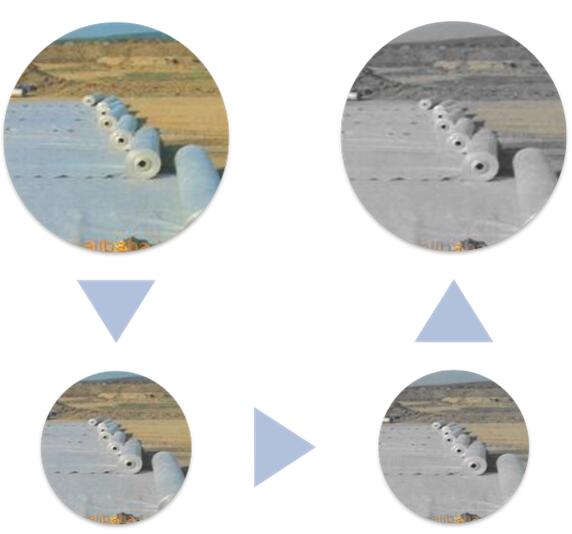

Geosynthetics

Classification of Weather Conditions Meter

If according to the type of light source, the above listed various artificial light source aging testing machine can be summarized into three categories: xenon arc lamp as the light source aging testing machine; Aging testing machine with carbon arc lamp as light source; And aging testing machine with mercury lamp as light source.

According to the type of test chamber: flat plane type and rotate-drum type.

Xenon arc tester

Water-Cooled Light Weather Fastness FY3600

Application:

Water-cooled Weather Conditions Meter. To determine the color fastness and aging to light, weather resistance, compound color fastness to light-sweat of colored textile, leather, leatheroid, plastic, etc, by setting various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. Be able to control irradiance real-time, automatically inspect and compensate irradiance, temperature, humidity.

Feature:

- Presetting various specifications, or customized programs, meet diverse range of standards,including AATCC, ISO, BS, JIS etc;

- Touch screen, and build-in PLC, real-time display the ongoing test’s graph, be able to presetting irradiance, temperature, humidity, and plot dynamic curve of them.

- 4500W water-cooled xenon arc lamp system, accurately simulate light spectrum. Irradiance auto-compensates system, control irradiance, temperature, and humidity timely through a closed loop.

- Irradiation control, light irradiance sensor monitor, digital setting, automatic compensating system, stepless irradiation regulation.

- Accurate chamber temperature control, irradiation temperature, and heater raise the temperature, air conditioning refrigeration system.

| Standard | ISO 105-B02/B04/B06, 4892-2, 11341 | AATCC TM16, TM169 ASTM G155-1/155-4 | JIS L0843 ,GMW 3414, SAEJ1960/1885, JASOM346, PV1303 |

Key Specification:

| Lamp power Supply | AC380V±5% 50Hz 9000w(Max) |

| Irradiation Source | 4500w water-cooled Long Xenon Arc Lamp |

| Average Lamp Life | 1500 hours |

| Rack Rotating Speed | 1-4r/min |

| Rack Outside Radius | 220mm (centered on the Xenon-arc Lamp) |

| Specimen Holder Exposure Area | 180×35mm (ISO) 190x50mm (AATCC) |

| Specimen Number | 27pcs (ISO); 18pcs(AATCC)(Max) |

| Illumination cycle adjustable | 0~9999h59min,±1s |

| Spray cycle adjustable | 0~9999h59min,±1s |

| Each specimen holder adjustable timing | 0~9999h59min,1s |

| Chamber Temperature Range | 30℃~80℃±2℃ |

| BPT | 30℃~80℃±2℃ |

| BST | 40℃~130℃±1℃ |

| Floor Space | 1500×3000mm (Min) |

YG611F Air-cooled Xenon Arc Tester

Application:

YG611F Air-Cooled Xenon Arc Tester is designed to simulate and strengthen light spectrum that reaches the ground by xenon arc lamp as light source, and supplemented by temperature and humidity control, and water spray conditions. Flat type xenon exposure systems to test long-term effects that light, heat and moisture will have on your products in their end-use environment. This kind of xenon tester is suitable for various kinds of materials, such as textile, leather, plastic, rubber, painting, dyestuff, etc.

Feature:

Chamber body materials

- Out shell uses high quality cold-rolled steel board and carries on spray treatment, bright, beautiful and easy to clean;

- Work chamber material is high quality SUS304 stainless steel board;

- Adopts double silica gel to seal the chamber door, good sealing and anti-aging performance.

Configuration

- Control system on the top of machine, including temperature control meter, button, and indicator;

- Upper part is light source area, 3 xenon lamps and filter located in it to provide stable and suitable simulative light;

- Middle part is working area; big sample tray can meet the demands of many kinds of sample size. Tray designed to drawer type make put and take out sample become easier and fast. Tray declines 10° allow flat and three-dimensional sample to be tested;

- Lower part is fan and water area.

Control system

- Adopts large programmable colorful touch screen, chamber temperature and humidity can be control and adjusted;

- Humidity and temperature sensor is high precision PT100 platinum resistor;

- High setting and display resolution: temperature 0.1℃, humidity 0.1RH%, time 0.1min;

- The irradiance can be adjusted automatically by the controller through adjusting the light intensity of the lamp.

Xenon arc lamp system

- Provided with three xenon lamps, composed of filter, trigger and power supply;

- Xenon arc lamp: high quality and certified lamp with long life.

Spray system

- Cupreous sprayer, incorrodible and rust-proof, it can be removed easily and spray capacity can be adjusted;

- Spray water pressure is 1~1.5bar;

- Equipped with two spray heads on the top of working chamber.

Safety protection system

- Water level protection;

- Power leakage protection;

- Over temperature and over current protection for fan;

- Auto-stop after fault alarm.

| Standard | ISO 4892-2, ISO 11341 | GB/T 16422.2, GB/T 1865 |

Key Specification:

| Xenon lamp power | 2500W*3, adjustable |

| Irradiance range | (1.10±0.02)W/(m 2nm)@420nm |

| Photoperiod | 1~999hour (adjustable) |

| Black panel temperature (BPT) | 50~90℃ |

| Temperature range | RT+10℃~+70℃ |

| Temperature fluctuation | ±0.5℃ |

| Temperature uniformity | ±2℃ |

| Heating power | 1kW |

| Humidity range | 85~98% RH |

| Humidity fluctuation | ±3% RH |

| Humidity uniformity | ±5% RH |

| Rainfall interval | 0~240min (adjustable) |

| Rainfall water pressure | 1~1.5bar |

YG611M Air-Cooled Xenon Arc Tester

Application:

YG611M Air-Cooled Xenon Arc Tester is used to determine the color fastness and aging to light, weather resistance, compound color fastness to light-perspiration of colored textile, leather, plastic, etc., by setting various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. Be able to control irradiance real-time, automatically inspect and compensate irradiance, temperature and humidity.

Feature:

- 10.4 inch color touch screen display, Windows operation system, brief control interface, few setting procedures and simple operation;

- Real-Time graphic display, the operator can easily get access to the test process;

- Independent controlling of each sample to test, samples’ test time is controlled separately, set the time for each specimen and when the set time is over, the corresponding specimen can be taken out and continue the test of remaining specimens; automatic reminding when each specimen’s test is over.

| Standard | ISO 105-B02/B04 | ASTM G155-1/155-4 | GB/T 8427/8430 |

| AATCC 16/169 | JIS L0843 | GMW 3414 |

Key Specification:

| Irradiation source | 2,400W Air-cooled Xenon Arc Lamp |

| Irradiance range | (0.80~2.01)W/m2+0.02W/m2@420nm |

| Rack rotating speed | 5rpm |

| Number of sample holders | 15pcs for ISO standard or 7pcs for AATCC standard |

| Cycle mode | Light,light & spray, dark, dark & spray |

| Program | Settable programs up to 100 pieces, steps for each program up to 200 |

| Temperature controlling range | 30~80℃ with resolution of 0.1℃ |

| Chamber temperature range | 30~65℃ with resolution of 0.1℃ |

| Humidity range | Light cycle: 10~85%R.H. Dark cycle: 30~100%R.H. |

| Humidity resolution | 1.0% |

| Humidity fluctuation | ±3% |

| Measuring range of BST | -55~125℃+0.1℃ |

| Power supply | AC380V,50Hz,3phase |

YG611T Air-cooled Xenon Arc Tester (desktop)

Application:

Bench Xenon Arc Tester is designed to simulate and strengthen light spectrum that reaches the ground by xenon arc lamp as light source, and supplemented by temperature and humidity control, and water spray conditions. This kind of xenon tester is suitable for various kinds of materials, such as textile, leather, plastic, rubber, painting, dyestuff etc.

Feature:

- 7 inch colorful touch panel, easy to set and monitor;

- Air-cooled 1800W xenon arc lamp to simulate light;

- Irradiance, temperature and humidity controlling system with water spray;

- Light-strength real-time auto calibration system;

- Stable performance with modular design and high.

| Standard | ISO 105 B02/B04 | ASTM D4355 | GB/T 8427/8430/14576 |

Key Specification:

| Light source | Air-cooled 1800W xenon arc lamp |

| Lamp service life | 1200h |

| Spectrum wavelength | 290nm~800nm |

| Irradiance range | (0.8~2.01W/m2+0.01W/m2)@420nm |

| Black panel temperature(BPT) | (30~100)℃±2 ℃ |

| Black standard temperature (BST) | (35~100)℃±12 ℃ |

| Chamber air temperature | (35~65)℃±2 ℃ |

| Humidity range | (20%~85%)RH+5%RH for light cycle (30%~90%)RH+5%RH for dark cycle |

| Photoperiod | 1~9999 hour (adjustable) |

| Number & Size of sample rack | 17 pieces of 110x50mm sample racks(standard) 8 pieces of 240×55mm sample racks (optional) |

| Operating environmental required | Temperature:25±5 ℃ |

| Relative humidity | 80%~40% (descent as temperature increases) |

Carbon Arc tester

Application:

YG611CS Carbon Arc Weather Conditions Meter artificially simulates outdoor conditions, such as light, temperature, humidity and rain; this instrument accelerates degradation of samples so as to estimate the life of products and materials in a short time.

Ultra long-life carbon rods (4 pairs) can light continuously for about 78 hours and it can set various parameters of irradiance, temperature, humidity, spray to simulate natural condition in lab. It’s widely used in the field of textile, leather, plastic, etc.

Feature:

- Touch screen, convenient to operate;

- Ultra long-life carbon rods (4 pairs) can light continuously for about 78 hours;

- Sunshine carbon arc lamp, the light source, uniquely controls the discharged voltage and current, thereby maintaining rated 50V and 60A and having a stable spectral distribution;

- Easily installable carbon holders allow easy replacement of carbon lamps;

- Vertical specimen racks of SUS316 stainless steel, resistant to acid, alkaline and irradiance, to ensure the uniformity of irradiance and spraying onto specimen;

- Inner sides of test chamber are made of stainless steel;

- Complete controlling system for chamber temperature and specimen temperature with over-temperature protection;

- Professional and reasonable design of test chamber and air circulating system to ensure the uniformity and accuracy of tests;

- Automatic controlling of relative humidity to meet astringent test method;

- Environment-protective carbon arc lamp cooling system;

- Different filter panels to simulate different outdoor test conditions;

- Alarm for low water and auto adding of water.

Standard:

| ISO 4892-1 | AATCC16-1,2 | NCCA |

| JIS A1415 | JIS B7753 | JIS D0205 |

| JIS G3312 | JIS H86885 | JIS K2246 |

| JIS K5400 | JIS Z9117 | ASTM G23 |

Key Specification:

| Irradiation Source | Sunshine carbon arc rods (4 pairs of ultra long-life carbon rods)/78 hours |

| Discharge voltage | 50V±2V |

| Discharge current | 60A±2A |

| Carbon electrodes | Upper: Φ36×410mm Lower: Φ23×410mm |

| Size of inner chamber | 1000×1000×1000mm(L×W×H) |

| Specimen racks | Standard 76pcs, 150×70mm for each |

| Total exposure area | 9800cm2 |

| Chamber temperature range | (35~80)℃ |

| BPT temperature range | (40~90)℃ |

| Temperature fluctuation | ±2℃ |

| Relative humidity | Light: 10~75% Dark: 10~95% |

| Relative humidity fluctuation | ±4% |

| Light cycle | 0~999.0 hours |

| Dark cycle | 0~999.0 hours |

| Spray | 0~999.0 hours |

| Power supply | AC380V 50Hz, single-phase |

Mercury light tester

DW601 Mercury-tungsten Light Fastness Tester

Application:

DW601 Mercury-Tungsten Light Fastness Tester is used to determine light fastness of textiles which exposure to mercury lamp.

Feature:

- Imported mercury lamp with original packaging;

- 500 watt high power lamp with long operating life.

| Standard | BS 1006 UK/TN |

Key Specification:

| Light source | 50o watt mercury lamp (imported) |

| Lamp life | 5000h |

| Distance between specimen and the center of lamp | 200±5mm |

| Exposure area | 1800cm2 |

| Dimensions | 500×550×570mm (W×DXH) |

| Power | AC220V,500w |

Introduction to ATLAS, QLAB and SUGA instruments

SUGA Xenon Weather Meter

Simulating outdoor and indoor environments of light, temperature, humidity, rain and dews, xenon weather meters accelerate degradation of materials exposed to those factors.

X25 is a relatively small-sized, light fastness testing apparatus with Suga 2.5-kW xenon arc lamp allowing ultraviolet irradiance between 40 W/m2 and 60 W/m2. This model is widely used for testing light fastness of packing materials, daily goods, and textile goods. X25 allows users to specify or adjust a maximum of 108specimens can be mounted on the rack.

Specification of X25

| Light source | 2.5-kW water-cooled xenon arc lamp* |

| Test types | Light only, Light & Spray on front face (Rain), Dark only |

| Irradiance | 40 W/m2 to 60 W/m2 at 300nm to 400nm(Quartz inner filter and #295 outer filter) |

| Temperature and humidity range | Light test : 63 ℃ to 83 ℃±2 ℃ of Black panel temperature(BPT),35%rh to 60 %rh ± 5 %rh (at 63 ℃ of BPT and 42 W/m2) |

| Dark test : 38 ℃±2 ℃ of Chamber temperature,95 %rh±5 %rh | |

| Quantity of specimen | Maximum 108 pieces (Specimen size: 65 mm x 55 mm, 1 mm thick) |

| Electrical requirements | Three-phase, 200 v, approx.36 A |

| External dimension | Approx. Width 90 cm, Depth 113 cm, and Height 183 cm (Weight: approx.350 kg) |

| Related standards | ISO,ASTM,JIS, and JASO(subject to different accessories) |

Spectral power distribution of Suga xenon arc lamp is similar to that of light for both ultraviolet and visible radiation. Using different combinations of inner and outer filters surrounding the lamp, X25 simulates solar spectral irradiance distributions in both indoor and outdoor conditions.

*XA25 is provided with an air-cooled xenon lamp requiring no cooling water.

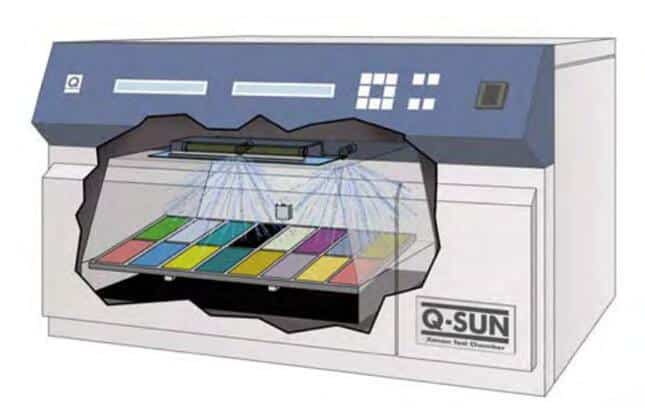

QLAB Light Fastness Tester

The Q-Sun Model B02 is a light fastness tester designed to meet the requirements of ISO 105 B02 and AATCC Test Method 16 standards. It has a rotating specimen rack and provides precise control of critical test parameters including spectrum, irradiance, relative humidity,chamber temperature and black standard temperature. Its capacity is 48% to 92% larger than comparable xenon testers.

Specifications

| Black Panel (Uninsulated) Temperatures | Light Cycle – B/SL Filter:50 ℃-115 ℃ Light Cycle – IR Filter:35 ℃ – 100 ℃ Dark Cycle:25℃-45 ℃ |

| Black Standard (Insulated) Temperatures | Light Cycle -B/SL Filter:55 ℃-125 ℃ Light Cycle – IR Filter:40 ℃- 110 ℃ Dark Cycle:25℃-45℃ |

| Irradiance | IR Filter:1.10 – 0.20 W/m2 at 420nm 42- 10 W/m2 at TUV 300-400nm B/SL Filter:1.10 – 0.20 W/m2 at 420nm 48 – 10 W/m2 at TUV 300-400nm |

| Relative Humidity | Maximum RH is possible:60%-20% only when BP temperature is less than 60℃ |

ATLAS Weatherometer

Xenotest® Alpha+ simulates and accelerates the natural weathering process providing reliable results regarding the long-term behavior of materials. It is the universal weathering instrument for testing light- and weather[1]fastness of any material, offering a variety of options to meet international standards and test methods.

Xenotest® Alpha+ features

- A large selection of optical filters to test various end-use conditions and weathering standards.

- Proven xenon lamp technology with long operating life to provide high irradiance levels with low thermal loads.

- Large color touch screen featuring multiple language capability for easier programming.

- Automatic control of irradiance and Black Standard Temperature (BST)at sample level.

- Automatic control and measurement of test chamber temperature and humidity.

- On screen display of diagnostics, program selection and parameter indication.

- Test assurance and reliability through microprocessor controlled parameter monitoring.

- Data output to a printer, RS232 or memory card.

- Optional control and calibration via XenoCal.

- Turning and non-turning mode.

- Specimen Spray System.

- XenoTouch Add-ons: Remote Control, Email Service, Online Monitoring.

Xenotest® Alpha+ Specifications

| Irradiance range: 300-400nm at sample level (in W/m2) | ||

| Filter system | Turning Mode | Non-turning Mode |

| XENOCHROME 300 XENOCHROME 320 | 21-93 W/m2 21-93 W/m2 | 40-180W/m2 40-180W/m2 |

| 10 window glass | 21-57 W /m2 | 40-110 W/m2 |

| Absorption filter lantern with: | ||

| 6IR+1 UV | 21-72 W/m2 | 40-140W/m2 |

| 7 IRsegments | 21-72 W/m2 | 40-140 W/m2 |

| 4lR+3 window segments | 21-72 W/m2 | 40-140 W/m2 |

| Daylight extended IR | 21-65 W/m2 | 40-125 W/m2 |

| IR absorption filter system 16H | 21-72 W/m2 | 40-140 W/m2 |

Temperature and Humidity Range

| Test chamber temperature: 30℃ to 70℃ |

| Black Standard Temperature: 40℃ to 130℃ |

| Relative humidity: 10 to 95% |

FAQs

FAQ: Common Questions About Light Fastness

Q1: What is the difference between natural and machine-based light fastness testing?

Natural testing uses sunlight but is time-consuming. Machine-based methods (e.g., xenon arc testers) accelerate results by simulating UV, temperature, and humidity cycles.

Q2: How do pH levels affect light fastness?

Neutral pH (6–7) minimizes chemical degradation of dyes. Acidic/alkaline conditions weaken bonds, reducing textile UV resistance ratings.

Q3: Which industries prioritize light fastness testing?

Textiles, automotive interiors, and geosynthetics top the list due to prolonged UV exposure risks.

Q4: What standards govern light fastness testing?

Key standards include ISO 105-B02 (textiles), AATCC TM16 (apparel), and ASTM G155 (plastics).

Q5: Can light fastness accelerators harm fabrics?

Yes, if incompatible with other chemicals. Always verify synergies during lightfastness optimization for synthetic materials.

Comments are closed.

We are impressed by the depth of research evident in this article.

Most people who read this blog entry will gain a deeper understanding of the topic at hand.

Go ahead and join the community of avid readers who have come to rely on this blog for enriching knowledge and meaningful discussions.