Everything You Need to Know about Contact Angle

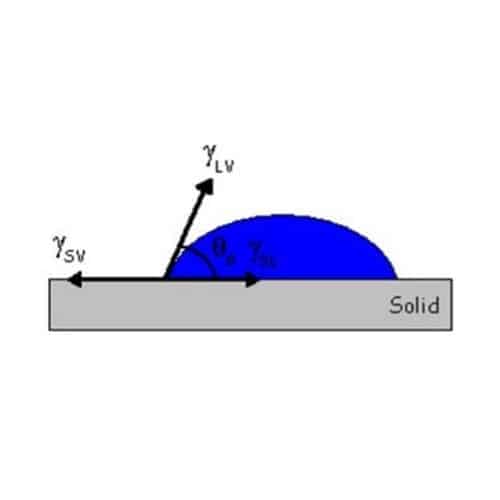

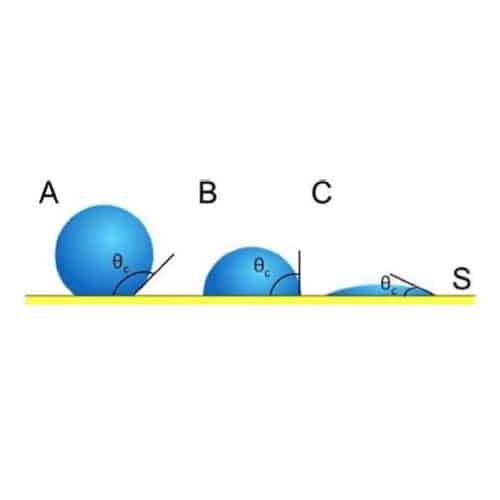

The contact angle refers to the angle formed when the liquid phase is sandwiched by the gas-liquid interface and the two tangents of the solid-liquid interface at the solid surface of a liquid drop on a solid horizontal plane. It is one of the important parameters that characterize the wettability of a liquid on a solid surface. It can be used to understand the degree of wetting of a liquid on a certain solid surface.

A contact angle measurement device is mainly used to measure the contact angle of liquid to solid, that is, the wettability of liquid to solid. It can measure the contact angle of various liquids with various materials. It is widely used in mineral flotation, water injection and oil recovery, washing, printing and dyeing, welding, etc.

Contents

Wetting

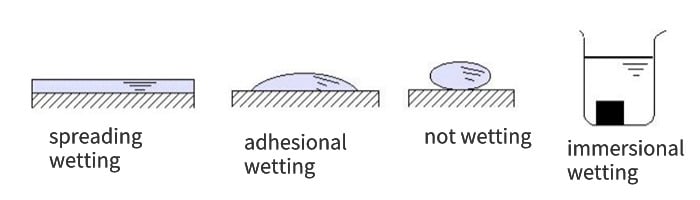

Before introducing contact angle, let’s first understand the concept of wetting. Wetting is a common phenomenon in nature and production processes. The process in which the solid-gas interface is replaced by the solid-liquid interface is usually called wetting. When liquids are dropped on a solid surface, due to different properties, some will spread out, while others will adhere to the surface and form a plano-convex lens shape. This phenomenon is called wetting. The former is called spreading wetting, and the latter is called adhesive wetting. For example, water droplets on a clean glass plate can produce spreading wetting. If the liquid does not stick and remains ellipsoidal, it is said to be non-wetting. Such as mercury dripping onto a glass pane or water dripping onto a tarp. In addition, if a solid that can be wetted by a liquid is completely immersed in the liquid, it is called wetting.

Whether a liquid wets a solid or not is not only determined by the strength of the attraction between solid and liquid molecules and between liquid and liquid molecules, but also by the repulsion between liquid molecules. When the gravitational force between solid and liquid molecules is large enough, the density of liquid molecules in the adhesion layer increases, and the repulsive stress between molecules becomes large, resulting in a situation where the liquid wets the solid.

When a liquid comes into contact with a solid, the free energy of the system decreases. Therefore, the degree of wetting of a liquid on a solid can be measured by how much the free energy of this process decreases. Under constant temperature and constant pressure, when a droplet is placed on a solid surface, the droplet can automatically spread on the solid surface, or exist as a droplet with a certain contact angle with the solid surface.

Contact angle definition

Narrow sense: refers to the angle θ between the tangent to the gas-liquid interface and the solid-liquid boundary line at the intersection of gas, liquid and solid;

Broadly sense: Contact angle is a system composed of three different interfaces interacting, and the angle θ between the interface lines of contact objects.

Factors affecting contact angle

The properties of solids and liquids, the influence of impurities and additives, the roughness and unevenness of the solid surface, surface contamination, etc. will all affect the size of the contact angle. In principle, polar solids are easily wetted by polar liquids, while non-polar solids are easily wetted by non-polar liquids. Glass is a polar solid, so it is easily wetted by water. For certain solid surfaces, adding surface active substances to the liquid phase can often improve the wetting properties. And as the contact time between liquid and solid surface prolongs, the contact angle tends to gradually decrease and approach a constant value. This is due to the adsorption of surface active substances on each interface.

Test methods

According to the directly measured physical quantities, it is divided into four categories: angle measurement method, length measurement method, force measurement method, and transmission measurement method. And among them, the droplet angle measurement method is the most commonly used and the most straightforward method. It drops a small droplet on a flat solid surface and directly measures the contact angle. To this end, you can use a protractor installed in a low-magnification microscope to measure, you can also project the droplet image onto a screen or take an image and then measure it with a protractor. These methods cannot avoid artificial tangent errors. If liquid vapor is adsorbed on the surface of a solid and affects the surface free energy of the solid, the sample should be placed in a sealed box with an observation window and measured after the system reaches equilibrium. The advantages of this method are: less sample consumption, simple instrument, and convenient measurement. The accuracy is generally around ±1.

Contact angle measurement device

V5 contact angle measurement device is used to measure the contact angle of a liquid to a solid surface. The angle of contact is regarded as one of the important parameters to measure the surface properties of solid materials, and it is also an important parameter of the surface wettability of the material. This system is widely used in many fields, such as modern industry, medicine, semiconductors, material protection, life science, and so on.

Contact angle is one of the important parameters in surface chemistry and physics. Through the measurement of contact angle, a lot of information about the solid-liquid and solid-air interface interactions on the material surface can be obtained. There are many measurement methods, and each has its own advantages and disadvantages. In actual operation, we should choose the appropriate measurement method according to the specific situation.

As a commonly used surface analysis technology, the measurement technology has many advantages, such as simple instruments and equipment, low price, easy operation, and large amount of information obtained. Therefore, it has important applications in improving oil recovery rate, biomedical materials, clean coal processing, chip industry, etc. In addition, contact angle measurement technology also has important applications in the characterization of inks, cosmetics, pesticide printing and dyeing, spraying, sewage treatment and other industries.

Comments are closed.

Read this blog for in-depth analysis and thoughtful commentary that goes beyond surface-level discussions.

More than just informative, this blog sparks curiosity and encourages readers to question and think critically.