Fabric Style and Fabric Touch Tester

As people’s living standards improve, their requirements for life are also gradually increasing. Textile, an industry closely related to life, has also developed rapidly. In particular, the comfort of clothing or home textile products is one of the most important concerns for consumers. Therefore, a comprehensive study on the relationship between fabric mechanical properties and style is crucial. Fabric style is an important indicator for evaluating the quality of textile products, and it is also an important factor affecting textile sales. Consumers mainly judge product quality through touch and vision. Fabric hand feel is an important factor affecting fabric performance and one of the important evaluation indicators for the comfort of textiles and clothing. Therefore, textile hand style measuring instruments have always been a research direction of close concern in the field of textile science and technology. It has become an urgent need to quantitatively evaluate fabric hand style correctly, effectively and objectively.

Contents

Definition of fabric style

In a broad sense, fabric style refers to the comprehensive effect produced by the inherent properties and shapes of the fabric itself on human sensory organs. Such as touch, vision, hearing, etc. In a narrow sense, it refers to the comprehensive reflection of certain physical and mechanical properties of fabrics caused by the touch of human hands.

Evaluation method

There are subjective and objective evaluation methods for fabric hand style. The subjective evaluation method is to form a comprehensive feeling of fabrics through human senses, and evaluate the hand characteristics and style of fabrics based on personal subjective scoring, sorting, description, statistics, analysis, and judgment. This method is the basis for evaluating the hand style of fabrics and is also the most basic and original method for evaluating the hand style of fabrics. However, this method has two shortcomings. First, the subjective evaluation method cannot eliminate subjective arbitrariness. Second, the subjective evaluation method lacks quantitative description. In order to overcome the shortcomings of subjective assessment methods,objective assessment methods came into being.

The objective evaluation method of fabric hand style refers to obtaining the physical and geometric quantities related to the fabric through instrument testing, and based on the sensory evaluation, establishing certain quantitative standards to evaluate the fabric, and making judgments on the hand style characteristics of the fabric. evaluate. This method overcomes the shortcomings of subjective evaluation methods and is now the main method for fabric hand style evaluation.

Textile style measuring instruments

KES-FB fabric style meter

KES-FB (full name Kawabata Evaluation System-Fabric) fabric style meter method is also called the Kawabata method. In 1970, several multi-measurement and multi-index fabric style meters were manufactured by Kawabata Nomoyo and others in Japan. It consists of tensile tester, shear performance tester, bending performance tester, compression performance and thickness tester, friction and surface roughness tester under low stress. The design mainly evaluates the fabric feel style, which is divided into three levels: basic mechanical quantity, basic style value HV and comprehensive style value THV. The basic mechanical parameters include 14 mechanical indicators and 2 physical indicators, which respectively reflect the tensile properties, compression properties, bending properties, shear properties, surface properties of the fabric and the thickness and weight characteristics of the fabric. The comprehensive style is a general sensory evaluation of fabric quality. In order to facilitate the establishment of quantitative correlation with the basic style of the fabric, the comprehensive style is divided into 0 to 5, a total of 6 categories, called the comprehensive style value of the fabric, recorded as THV.

The KES-FB system tests 6 properties including tensile, shear, bending, compression, surface properties and thickness properties of fabrics under low stress. A total of 16 indicators were measured. Subsequently, some of these indicators were also used to predict the garment processing performance of fabrics, especially wool fabrics.

Disadvantages of KES-FB Fabric Style Meter: Since its basic style value and comprehensive style value are evaluated by Japanese experts, it has certain regional limitations. In view of the fact that people in different countries have different preferences for fabric styles due to different cultural backgrounds and differences in living environments. The multiple regression transformation formulas from basic mechanical quantities to basic style values and from basic style values to comprehensive style values obtained from other analyzes are not applicable to every country.

A series of instruments composed of different mechanical property instruments. Only one mechanical property can be tested on one instrument, and multiple properties cannot be tested on the same instrument. The KES-FB system test cannot represent and judge the difference between each basic feel (firmness, fullness, etc.), and there is still repeatability among its indicators. This instrument has high measurement accuracy, but it has many test indicators, time-consuming measurement, complex test process and data processing, and is expensive.

FAST Fabric Styler

FAST (full name: Fabric Assurance by Simple Testing) Fabric Style Tester is a wool fabric property testing system developed by the Australian Commonwealth Institute of Science and Industry in 1990. It is used to measure the impact of fabric properties on cutting and sewing performance and garment appearance. It mainly It is oriented towards product processing. This testing system consists of 3 simple testing instruments and a set of testing methods, specially designed for wool fabric production, finishing and quality management of garment manufacturing plants. Three of the instruments and one test method are the FAST-1 compression meter, the FAST-2 bending meter, the FAST-3 low tension extensometer and the FAST-4 fabric dimensional stability meter. Like the KES-FB fabric style meter, it also measures the physical and mechanical properties of fabrics under small stress. It measures the four basic mechanical properties of fabrics: compression, tension, bending, and shear. It tests different properties through different FAST series instruments. performance. Draw a “fabric fingerprint” based on the above performance indicators to indicate the performance of the fabric being tested and to evaluate the feel of the fabric. The main differences are: ① The bending stiffness tester of KES-FB measures pure bending, while the measurement principle of the FAST bending tester is the inclined plane method; ② The FAST system measures oblique tension, but KES-FB does not have this indicator; ③ The KES-FB test For shear stiffness, the specimen length is fixed, and FAST shear stiffness is calculated from the diagonal elongation of the fabric under a load of 5 cN/cm.

The advantages of FAST fabric style tester – this system tests the four basic mechanical properties and dimensional stability of fabrics under small load and small deformation: compression, tension, bending and shearing. The key point is to predict the formability of fabrics, especially Garment processing properties of wool fabrics. Compared with the KES system, its measurement accuracy is not high, but the test is simple and the price is relatively cheap.

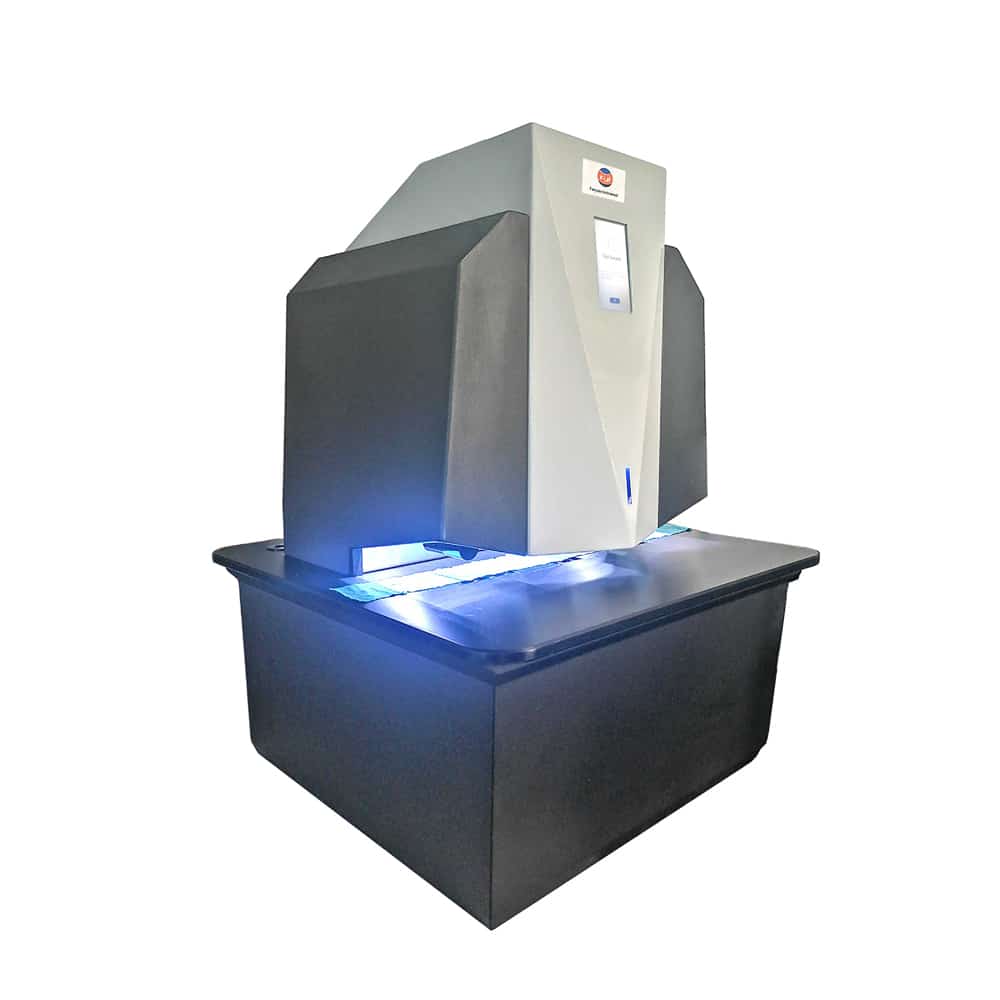

Fabric Touch Tester

The Fabric Touch Tester, also named the Comprehensive Handle Evaluation System for Fabric and Yarn, measures skin touch properties by simulating hand touch fabric movements of tensile, compression, pinch, knead, bending, compression, friction, tension, getting the indices of softness, stiffness, smoothness, and tightness, and objectively evaluating the hand and touch feel of fabrics.

Comments are closed.

Find yourself returning to this blog time and time again for its quality content.