The fabric of small circular knitting machine

The fabric of small circular knitting machine is belong to weft knitted fabric. It can be used for the yarn uniformity assessment and the dyeing affinity quality control of yarn.

Contents

How to produce this fabric

We often use two types of machines to produce fabrics. Generally, weaving machine produces the woven fabric, knitting machine manufactures the knitted fabric.

This fabric was made by small circular knitting machine, as shown above.

Weaving

Weaving is the process of forming woven fabrics with yarn as warp and weft according to different fabric structures. It usually consists of three parts:

- At first, making warp yarn into weaving shaft

- Then, making weft yarn into twisting (or bobbin)

- At last, weaving and finishing

Weaving is an important part of the textile industry production. Based on the type of raw materials. We can divide weaving into cotton weaving, wool weaving, silk weaving and hemp weaving. All in all, all of the products are woven fabric.

Knitting

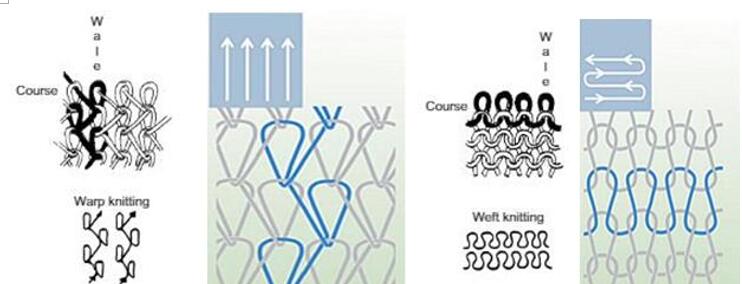

Knitting is the process of using knitting needles to form coils of various materials and yarns. After that, the needles connect them into knitted fabrics. Knitwear products are also suit for industry and agriculture, medical care and national defense, etc. In this process, the yarn can be wound horizontally or longitudinally. Cross knitted fabric is weft knitting and longitudinal knitting is warp knitting. The picture below shows the winding patterns of warp and weft knitting.

The differences between woven fabric and knitted fabric

| Woven fabric | Knitted fabric | |

| Organization structure | The fabric consisting of two or more groups of perpendicular yarns interwoven at 90 degree angles. | The yarn is sequentially bent into coils, and the coils are wrapped in each other to form the fabric. |

| Basic unit of fabric organization | Each intersection point between warp and weft is tissue point. This tissue point is the smallest basic unit of woven fabric. | The coil is the smallest basic unit of a knitted fabric. And the coil consists of a spatial curve of coiled and extended threads |

| Characteristics of fabric structure | There is little relation between warp and weft extension and contraction. So the fabric is generally compact and stiff. | Knitted fabric can stretch in all directions, it’s very elastic. Because knitted fabric is formed by the hole coil. It has great permeability and soft feel. |

To know the difference between wrap and weft knitting fabric, you can read this article.

The characteristics of the fabric

The fabric of small circular knitting machine has the same characteristics as knitted fabric. It is soft in texture. What’s more, it has good crease resistance and permeability. Besides these, it also has greater extensibility and elasticity. We may feel comfortable if wear the knitted fabric at the same time.

Who needs the fabric of small circular knitting machine

Many laboratory and university researchers buy small circular knitting machine for dyeing test. Moreover, it also suit for chemical fiber manufacturers, weaving factories, printing and dyeing factories.

Our company provides the small circular knitting machine which can produce this fabric for dyeing test. You can send email to [email protected] to get more information.

Comments are closed.

good post and really beautiful great inpiration you have.

Why haven’t I come across this blog earlier? It’s exceptional!