Bending Beam Rheometer DW5325

DW5325 Bending Beam Rheometer is used for determining the flexural creep stiffness of asphalt, so as to evaluate the low-temperature cracking performance of asphalt binder. The BBR test method is applicable to unaged asphalt or asphalt aged using aging procedures such as rolling thin film oven or pressure aging vessel.

Bending Beam Rheometer DW5320 Description

DW5325 Bending Beam Rheometer is used for determining the flexural creep stiffness of asphalt, so as to evaluate the low-temperature cracking performance of asphalt binder.

Follows are features of the machine:

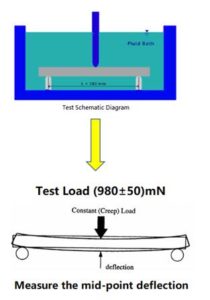

- The instrument mainly consists of a loading system with specimen support, a controlled-temperature liquid bath and a computer-controlled data acquisition system;

- A prismatic test specimen is placed in the controlled-temperature liquid bath and subjected to a constant test load (980±50)mN applied to its mid-point for 240s;

feature of bending beam rheometer

- It’s equipped with air bearing loading mechanism to apply specified load to the specimen and high precision displacement sensor to measure the deflection of the specimen;

- Full automatic test: Touch screen control, microcomputer display load, displacement and liquid bath temperature, easy to set the parameters, in the test process real-time display load, displacement and liquid bath temperature curve;

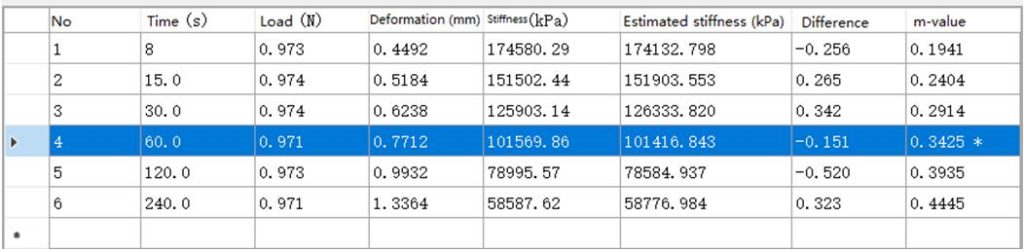

- Test results including stiffness and m-value can be obtained through professional software automatically;

feature of bending beam rheometer

- Beautiful in design and durable: Adopt stainless steel loading shaft and stainless steel specimen support. The main machine table adopts 2mm thick stainless steel material. The lining is 5mm thick tetrafluoroethylene material with effective heat insulation and good corrosion resistance.

Application

Application of Bending Beam Rheometer

DW5325 Bending Beam Rheometer is used for determining the flexural creep stiffness of asphalt, so as to evaluate the low-temperature cracking performance of asphalt binder. The BBR test method is applicable to unaged asphalt or asphalt aged using aging procedures such as rolling thin film oven or pressure aging vessel.

Bending Beam Rheometer complies with ASTM D6648, AASHTO T313-09 , EN 14771-2012,JTG E20-2011,SH/T 0775-2005 international and retailer standards.

If you need more information about Bending Beam Rheometer Testing Machine. Please contact with us

Standards

Standards of Bending Beam Rheometer

| AASHTO T313-09 | ASTM D6648 | EN 14771-2012 | JTG E20-2011 | SH/T 0775-2005 |

|---|

Some standards might not be the full version; to read the full version for free, write an email to [email protected].

Please contact the administrator to get any violations removed.

Key specification

Key specification of Bending Beam Rheometer

| Loading shaft | Made of stainless steel

With a spherical contact point 6.3±1.3mm in radius |

|---|---|

| Load cell | Max. load: 500g |

| Test load range | 0~350g, adjustable |

| Load accuracy | ±1g(±10mN) |

| Contact load | 35±10mN |

| Test load | 980±50mN |

| Load resolution | 1mN |

| Specimen support | Made of stainless steel, spaced 102±1mm apart |

| Displacement sensor | 0~10mm, resolution: 1μm |

| Temperature control range | -36℃ to 0℃, accuracy: ±0.1℃ |

| Control mode | Touch screen control |

| Data display | Microcomputer display load, displacement and liquid bath temperature, easy to set the parameters, in the test process real-time display load, displacement and liquid bath temperature curve |

| Compressed air | 0.8Mpa, clean, dry air supply required |

| Power Supply | AC220V, 50Hz, 500W |

| Dimensions | 600×600×550mm (L×W×H) |

You must be logged in to post a review.

Reviews

There are no reviews yet.