The Most Valuable Guide to Jigger Dyeing Machine Selection-2

We have discussed the technical characteristics, classification, and development of domestic jigger dyeing machines before. Here are eight foreign jigger dyeing machines and information on how to choose the right one for you.

Contents

Foreign jigger dyeing machine

1. OTTO-PRICKEN from Germany

OTTO-PRICKEN normal temperature jigger dyeing machine

The machine has a straightforward dyeing tank layout. A specially created spreading device minimizes the number of lanes, which cuts down on the amount of time and water used. Additionally, the jigger’s simple and unique tank design gives it a very flexible production capacity, allowing it to meet the needs of both small and large orders on the same machine.

The main determining parameters for dyeing are temperature, tension, speed, time, water level, dosage, and liquor ratio (1:2). In order to guarantee the reproducibility of dyeing outcomes, the OTTO-PRICKEN jigger can adjust and monitor these elements in real time.

Equipment performance

- Driving an inverter motor.

- Control over swing time and track number.

- Control over output speed and tension.

- Precise system for dosing.

- Remote control and service.

- An accurate measurement of the fabric’s length.

- Monitoring and recording of water, power, steam, and dye usage.

- Excellent reproducibility.

- The fabric is free of wrinkles and scrapes.

- There is no edge color variation as well as no head or tail color variation.

Technical Parameters

| Roll width | 1600/4000mm |

| Roll diameter | 700/1100/1400mm |

| cloth speed | 0-180m/min |

| tension | 0-150kg |

OTTO-PRICKEN HTHP jigger dyeing machine

The high temperature and high pressure OTTO-PRICKEN jigger dyeing machine is appropriate for dying polyester and polyamide fibers as well as fabrics made of those fibers together. The tension and pace of the fabric are constant. The surface of the fabric won’t be creased or scratched throughout the dying process. Edge-to-edge and head-to-tail chromatic aberration are absent. The motor control opens and closes the cylinder head. The hydraulic stations and sensors that make up the safety locking system enable automatic operation.

Device configuration

- Safety lock on the cylinder head.

- Circulation pump.

- In/Out device.

- Dosing apparatus.

- A 250-liter barrel.

- Gadget for automatic stagger.

- Filtering system.

- Washing system with overflow.

- Emergency stop control.

- Remote Support.

- Alarm mechanism.

Technical Parameters

| Roll width | 1600/4000mm |

| Roll diameter | 700/1100/1400mm |

| Maximum temperature | 143℃ |

| Maximum pressure | 3.5bar |

2. Thies from Germany

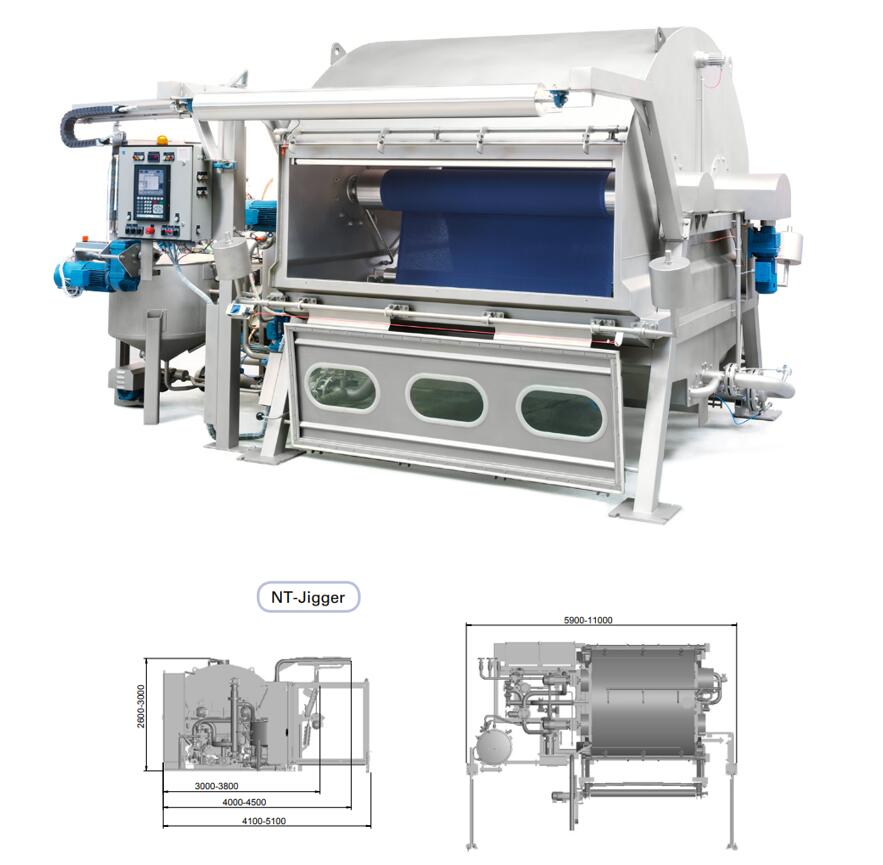

Thies normal temperature jigger dyeing machine

The Thies jigger dyeing machine is the good option for dyeing all synthetic and blended fabrics, and it can be used to process open-width fabrics that are prone to wrinkles. At 98°C, the NT-type jigger can dye fabrics without applying pressure, and at 140°C, the HT-type jiggers can apply high pressure to the process. Both versions provide uniform dying at low liquor ratios, continuous fabric tension and speed control, and a cost-effective dye tank design.

Both the NT-Type and HT-Type jigger dyeing machines are entirely constructed of stainless steel. The fabric is loaded and unloaded using the frequency-controlled A-frame drive at the set winding tension. The pace and tension of the fabric are calculated by and controlled by the fabric length controller. With the help of the weft device, the fabric can be coiled sideways during loading. High-efficiency variable frequency motors directly drive both main rollers.

Technical Parameters

| Main cylinder diameter(mm) | cylinder diameter (mm) | Roll diameter (mm) | Maximum width of fabric (mm) | Speed(m/min) | Tension (N) |

| 1000 | 1800 | 400 | 250 | 10-150 | 50-800 |

| 2000 | 1600-5400 | 1000 | 1800 | 10-150 | 50-800 |

| 2300 | 1600-5400 | 1230 | 2850 | 10-150 | 50-800 |

| 2800 | 1600-5400 | 1450 | 4100 | 10-150 | 50-800 |

Thies HTHP jigger dyeing machine

3. MEZZERA in Italy

With more than 60 years in business, MEZZERA has sold thousands of equipment all over the world. They provide consumers jigger dyeing machines in small, medium, and large sizes, among other sizes. Based on more than 40 years of manufacturing expertise and cutting-edge production technology, MEZZERA manufactures the newest machines.

Device Features

- Drive System: The jigger is equipped with two independent motors, driven at variable speed by independent AC vector inverters.

- Speed regulation:The circuit uses a high-resolution encoder to precisely control the speed in response to changes in the cloth’s diameter.

- Tension control: Use the PLC to determine the necessary tension based on the fabric’s specifications. The load cell, which is situated on the back roller underneath the dyeing tank, measures the tension of the fabric in real-time and feeds back the signal to the PLC. If there is a difference between the set value and the measured value, the synchronous AC motor through the frequency converter can immediately set it to zero. The procedure is entirely automatic, and the technology offers a quick, precise way to account for variations in cycle tension.

Technical Parameters

| Roll diameter | 500 mm、800 mm、1050 mm、1300mm |

| Maximum temperature | 143℃ |

| Fabric width | 1800-3600mm |

| Speed of work | 30-150m/min |

4. MCS from Italy

Currently, MCS Jigger dyeing machine has five high-temperature jiggers, three of which have a maximum temperature range of 143 °C and two of which have a maximum temperature range of 110 °C. There are additionally 4 jiggers with regular temperatures, with a top temperature of 98°C.

Comby high temperature jigger (143℃) technical parameters

| Roll width | 2000mm |

| Fabric width | 1800mm |

| Maximum roll diameter | 1100 mm |

| Main cylinder diameter | 325 mm |

| Fabric tension | 5-100kg |

| Maximum temperature | 143°C |

| Maximum pressure | 3 bar |

| Cloth speed | 0-150m/min |

Different types of roll diameter

| Types | Roll diameter |

| C4 COMBY jigger(143℃) | 2*750mm |

| COMBY jigger(143℃) | 1100mm |

| Compact jigger(143℃) | 650mm |

| COMBY jigger(110℃) | 1300mm |

| Compact jigger(110℃) | 650mm |

| Large jigger (98℃) | 1400mm |

| Medium jigger (98℃) | 1100mm |

| Small Jigger (98℃) | 850mm |

| Mini Jigger (98℃) | 650mm |

5. HENRIKSEN from the Netherlands

HENRIKSEN HTHP jigger dyeing machine

The HT jigger dyeing machine is mostly used to dye cotton, polyester, polyamide, and garments made from a combination of these fibers. A special driving mechanism that is built into every jigger perfectly maintains fabric tension and monitors shrinkage and elongation. These characteristics make sure the fabric doesn’t crease as it moves.

An innovative control system ensures right-first-time processing and consistent outcomes by controlling temperature, chemical dosage, bath ratio, and process time.

Device Configuration

- Equipped with water level gauge

- AC Motors and Electronic Drives

- Unique drive algorithm

- Main cylinder capacity 316L

- Ceramic Low Friction Bearings

- External heat exchanger for cooling and heating

- With feed tank and feed pump

Technical Parameters

| Model | Roll width(mm) | Roll diameter(mm) | Maximum temperature | Maximum pressure |

| HT700-2200 HT700-2800 HT700-3400 | 2200 2800 3400 | 700 | 143°C | 3bar |

| HT1200-2200 HT1200-2800 HT1200-3400 | 2200 2800 3400 | 1200 | 143°C | 3bar |

| HT1400-2200 HT1400-2800 HT1400-3400 | 2200 2800 3400 | 1400 | 143°C | 3bar |

HENRIKSEN normal temperature jigger dyeing machine

The NT jigger dyeing machine’s primary use is to pre-treat, dye, and wash a variety of fiber fabrics including polyamide fabrics.

Technical Parameters

| Model | Roll width(mm) | Roll diameter(mm) |

| AT700-1800 AT700-3600 | 1800 3600 | 700 |

| AT1100-1800 AT1100-3600 | 1800 3600 | 1100 |

| AT1400-1800 AT1400-3600 | 1800 3600 | 1400 |

6. MEMNUM in Turkey

MEMNUM HTHP jigger dyeing machine

Technical parameters

| Model | Temperature | Fabric speed | Roll width(mm) | Roll diameter(mm) |

| HTJ-2000 | 143℃ | 10-150m/min | 2000 | 1000 |

| HTJ-2400 | 143℃ | 10-150m/min | 2400 | 1000 |

| HTJ-2800 | 143℃ | 10-150m/min | 2800 | 1000 |

| HTJ-3400 | 143℃ | 10-150m/min | 3400 | 1000 |

The MEMNUM high-temperature, high-pressure jigger can dye cotton, polyester, nylon, viscose, and mixed materials. The MEMNUM jigger uses less water and has continuous speed and tension. All pre-finishing procedures, including bleaching, washing, and desizing, can be done in addition to dyeing.

Equipment performance

- Servo Control: Servo motors regulate tension and consistent speed. The servo motor can eliminate both the color difference on the fabric’s two sides as well as the fabric’s wave change.

- Edge control system for fabrics: The moveable drum (which moves left and right) prevents the edges of the fabric from curling during loading.

- PLC control: The working speed and cycle time are both quick when using PLC control. Staining programs can be saved in great numbers.

Main functions

- Data gathering is simple and quick thanks to an intuitive operator panel and process tracking with a graphical display.

- Modalities of automatic and manual control.

- PLC-controlled feeding apparatus.

- Homogeneity of the liquid using a circulating pump.

- Proportionately ramp up to high temperature

- System for direct heating.

- Acceleration and deceleration of servo motors are steady.

- Cleanable filter system.

- Having a feed tank (with mixer).

MEMNUM normal temperature jiger dyeing machine

Technical parameters

| Model | Roll width(mm) | Roll diameter(mm) |

| ATJ-700 | 2000/2400/2800/3400 | 700 |

| ATJ-1100 | 2000/2400/2800/3400 | 1100 |

| ATJ-1400 | 2000/2400/2800/3400 | 1400 |

7. SUNGMOO in South Korea

SUNGMOO HTHP jigger dyeing machine

This machine can dye a variety of materials, including cotton, acrylic, nylon, polyester, cotton, and polyester. successfully avert stains and spills, lessen heat loss, and conserve energy. Particularly excellent for wide fabric coloring.

Features

- Constant speed: The software runs at a steady speed while the cloth is being worked on, which helps to prevent uneven fabric coloring and ensure product quality. Fully automatic operation, programmable standard dyeing techniques, and lower labor costs than competing manufacturers. The control panel is simple to use, and the operator can quickly understand all the processing conditions thanks to the additional monitor. The machine conducts the entire process automatically in accordance with the program.

- Constant tension: During the dyeing process, the system regulates the tension and keeps it steady. It also allows for nearly tension-free dyeing of sensitive or light-colored materials.

- Gearing: Without the use of additional brakes, the dynamic torque control system and the vector drive system can accurately regulate the speed.

- Mechanism with automatic locking: When the machine’s temperature rises above the set temperature, the device locks the door.

Technical parameters

| Model | Roll width | Roll diameter(mm) | Fabric speed(m/min) | Maximum temperature(℃) | Maximum pressure(Kg/cm) |

| B80-600 | 80〞(2000mm) | 600 | 20~130 | 135 | 4 |

| B80-900 | 80〞(2000mm) | 900 | 20~130 | 135 | 4 |

| B80-1100 | 80〞(2000mm) | 1100 | 20~130 | 135 | 4 |

| B100-900 | 100〞2500mm) | 900 | 20~130 | 135 | 4 |

| B100-1100 | 100〞(2500mm) | 1100 | 20~130 | 135 | 4 |

| B110-900 | 110〞(2800mm) | 900 | 20~130 | 135 | 4 |

| B120-900 | 120〞(3000mm) | 900 | 20~130 | 135 | 4 |

| B130-900 | 130〞(3300mm) | 900 | 20~130 | 135 | 4 |

SUNGMOO normal temperature jigger dyeing machine

During the jigging operation, the SUNGMOO Jigger dyeing machine features an automatic system that properly distributes the fabric’s edges. One worker may operate many machines, which minimizes labor expenses and improves fabric quality and edge breakage.

Technical parameters

| Model | Roll width | Roll diameter(mm) | Fabric speed(m/min) |

| A80-600 | 80〞(2000mm) | 600 | 20~130 |

| A80-900 | 80〞(2000mm) | 900 | 20~130 |

| A80-1100 | 80〞(2000mm) | 1100 | 20~130 |

| A80-1300 | 80〞(2000mm) | 1300 | 20~130 |

| A100-900 | 100〞(2500mm) | 900 | 20~130 |

| A100-1100 | 100〞(2500mm) | 1100 | 20~130 |

| A100-1300 | 100〞(2500mm) | 1300 | 20~130 |

| A110-900 | 110〞(2800mm) | 900 | 20~130 |

| A110-1100 | 110〞(2800mm) | 1100 | 20~130 |

| A110-1300 | 110〞(2800mm) | 1300 | 20~130 |

| A130-900 | 130〞(3300mm) | 900 | 20~130 |

| A130-1100 | 130〞(3300mm) | 1100 | 20~130 |

| A130-1300 | 130〞(3300mm) | 1300 | 20~130 |

8. BHATT BROS from India

Features

- The program and controller are fully automatic.

- Control mechanism for constant tension.

- Low energy consumption and low liquor ratio.

- One can preset the tension.

- To prevent curling, the telescoping swings automatically.

- To repeat the procedure, program and store staining programs.

- The safety of the door is ensured by the pneumatic piston and check valve.

- apparatus for winding fabric.

The automatic room temperature jigger is one of the most advanced automatic dyeing and bleaching machines. It has two primary rollers, each of which has a separate and coordinated driving force, and a constant and adjustable tension control system, which maintains a constant dyeing and bath ratio throughout the cloth. The pneumatically sealed door decreases heat loss, keeps the temperature consistent, and limits exposure of the dye solution and fabric to the air.

Technical parameters

| Maximum fabric width | 3600mm |

| Maximum roll width | 3800mm |

| Cloth speed | 0 – 125 m/min |

| Heating method | Steam heating |

| Maximum edge stroke | 25mm |

| Tension | 5-50kg |

| Maximum roll diameter | 1500mm |

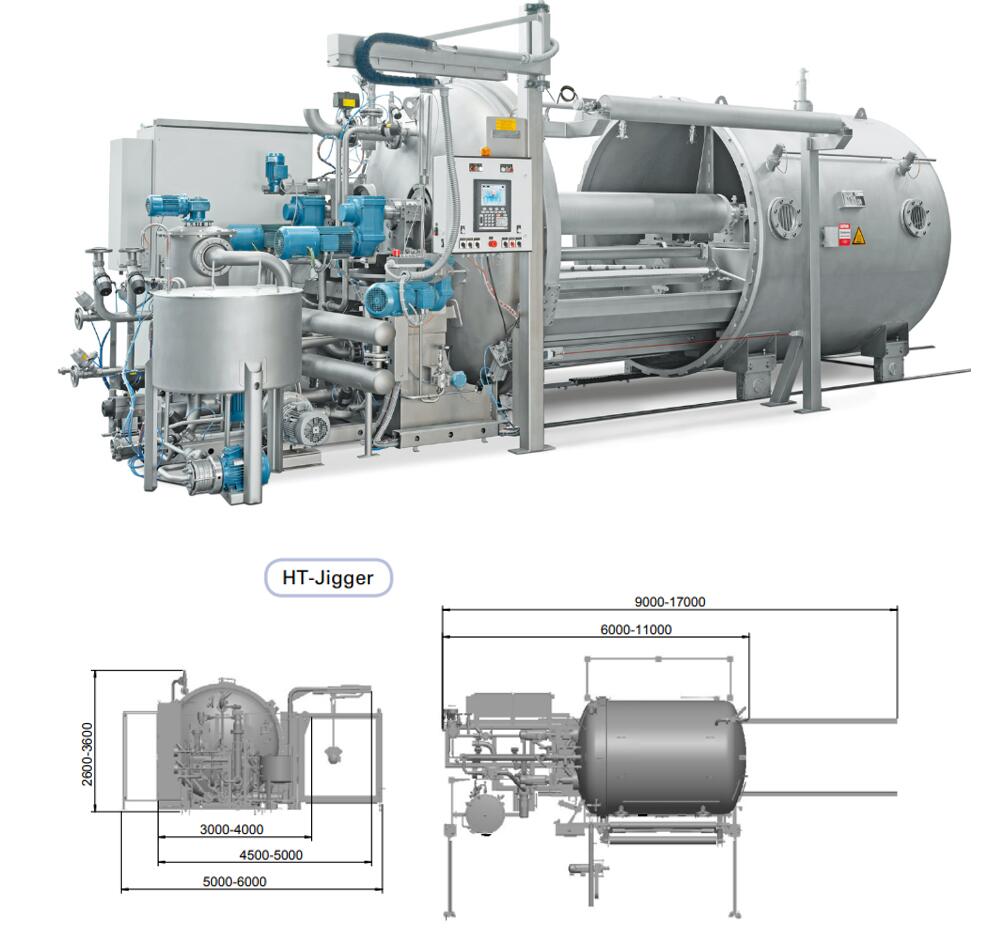

Summary of jigger parameters and prices of various manufacturers

Best solution for jigger dyeing machine

The head print, dark and light ends, dark and light borders, wrinkle, weft skew, loose plate printing, color pattern, color difference, and color file are among the usual issues with jiggers. According to its own knowledge and design, the German OTTOPRICKEN jigger is capable of solving most inquiries.

The German SEDO electronic control system is used by OTTOPRICKEN. Other electronic control techniques are not entirely effective at controlling tension, particularly when producing certain fabrics that call for high tension.

The PLC from OTTO PRICKEN can track water, power, and steam usage, support more than 100 different languages, and display key data like dye status, master tank liquid level, speed, tension, process stage, and so forth. The entire jigger has been given rust and acid resistance treatments.

The reports on jigger dyeing machine from OTTO PRICKEN and other manufacturers are summarized here. Please email [email protected] for particular dyeing report data.

| Brands | OTTO PRICKEN | HENRIKSEN | MEZZERA |

| Consumable Dyes (Total EUR/100kg) | 43.21 | 68.31 | 76.34 |

| Water consumption (total EUR/100kg) | 51.77 | 81.93 | 101.21 |

| brand | Standard Jigger dyeing machine | OTTO PRICKEN |

| Time (min) | 12604.5 | 12479.35 |

| Energy consumption (KJ/kg fabric) | 3499.1 | 988.31 |

| Water consumption (L) | 63400 | 12750 |

| brand | VH jigger dyeing machine | OTTO PRICKEN |

| Time to load/unload 1000 meters of fabric (min) | 6-7 | 10 |

| Drainage time (min) | 6 | 18.5 |

| Time to heat up to 98°C (min) | 14.5 | 18 |

The dyeing report’s survey findings indicate that when compared to other jiggers, the OTTO PRICKEN can save time, water, power, and money. As a result, if you have enough money, you can choose the jigger made by OTTO PRICKEN, which costs between 180,000 and 200,000 euros. If money is tight, you might choose a GOLDENSON jigger, whether it is a large or small-batch dyeing equipment. The best option for buyers is the GOLDENSON jigger dyeing machine due to its superior performance and high price performance. Please email [email protected] for a complete quote.

Comments are closed.

You know your projects stand out of the herd. There is something special about them. It seems to me all of them are really brilliant!

Very detailed report, it can be seen that you put a lot of effort into this

Thank a lot for sharing this with is it very nice and amazing and you have done excellent job. I enjoyed your blog.

You provided us with such an excellent post to read, illuminating every topic for us to learn more about.

Thank a lot. You have done excellent job. I enjoyed your blog .