FAQs of The Twisting Machine

Contents

- 1 What is twisting technology?

- 2 What is the use of twisting machine?

- 3 What is the effect of twisting?

- 4 What are the benefits of twister machine exercise?

- 5 What materials can be twisted?

- 6 Application of double twist machine in textile industry

- 7 What is the difference between spinning and twisting?

- 8 DW7051H Lab Twisting Machine

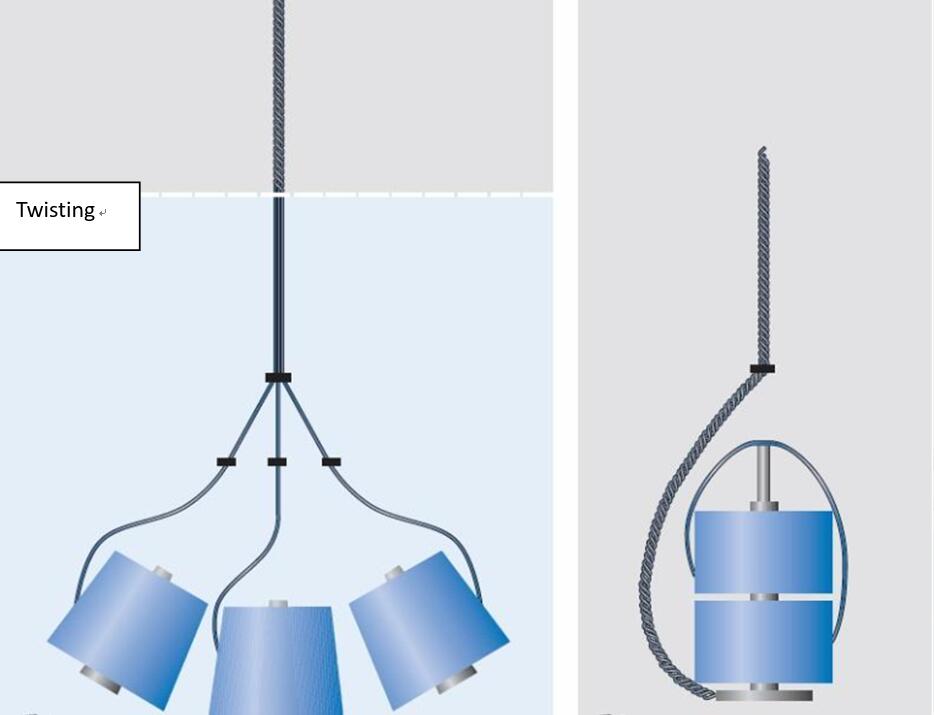

What is twisting technology?

The process of combining yarn is the preparation process of yarn twisting or yarn doubling. However, two or more yarns are twisted, resulting in a yarn of higher strength, greater uniformity, special color combination and special structure. From a single yarn, the production of twisted yarns is divided into two stages: several yarns are first combined on a spinning machine, and then twisted together on a twisting machine.

The weaving process is the first stage and the twisting process is the second stage. When using double twisting machine or ingot can twisting machine, with three or more yarns to produce twisted yarn, the process of merging is essential. For two strands of yarn, there are two process lines that can be applied in double twist: First, the classic method of double twist winding is used. The second method is to use two single yarns rolled up and down the double supply of yarn rolling placement.

What is the use of twisting machine?

Double twist machine is a kind of twisting equipment, which can realize one turn and two twists, and the twisting efficiency is doubled compared with the traditional twisting equipment. The increase of the volume, ten thousand meters without joint, twisting quality is greatly improved, low storey, especially suitable for operation.

Double twist machine features: high output, high degree of mechanical and electrical integration, low energy consumption, high quality, convenient operation. Large volume and high yield. Double twist machine adopts full computer automatic control system to ensure good positioning accuracy and running stability. Use high quality parts, low loss, long service life. Special roller design, avoid yarn winding, improve yarn quality. PLC operation frequency conversion stepless speed regulation, adapt to a variety of process requirements, low maintenance cost.

Working principle

Double twist machine can glue two or more strands of single yarn into yarn by twisting, and enhance the performance of the original yarn, to meet the needs of customers.

Possible faults

The main faults are generally weak twist, strong twist and no twist

What is the effect of twisting?

The experiment in the textile factory shows that the speed of the twister can be increased by 10% without increasing the breakage. This is due to the fact that the two yarns are balanced and stressed evenly when the parallel rolls are mounted. So you get higher productivity.

Therefore, these advantages generated by parallel winding are of great significance, indicating that the parallel winding process can not be cancelled. It is better to consider the merits of a particular situation before making a decision.

What are the benefits of twister machine exercise?

1.The spindle can get two twists per turn, so the output is high.

2. Make the bobbin in large rolls directly, save a winding process.

3. No steel collar wire ring, ingot speed is not limited by the speed of the wire ring, reduce the yarn oil.

4. Fewer processes, large roll, can improve labor productivity.

What materials can be twisted?

Application: polyester low elastic yarn, nylon high elastic yarn twisting. A chemical fiber filament made of synthetic fiber thermoplasticity with permanent nonlinear crimp, fluffy and elastic. Yarn can be used to make knitted outerwear, can also be used to weave strength socks, underwear, sportswear, gloves and other knitted fabrics.

Application of double twist machine in textile industry

The traditional mechanical twist machine

Due to the limitations of the speed, forming effect and maintenance of traditional mechanical forming, many spinning machine manufacturing enterprises are committed to the research and development of electronic forming twirling machine in recent years. However, due to the limitations of the molding control accuracy, anti-folding algorithm and other problems, the actual equipment put into the market is not very mature. The servo forming electrical control system of Sanacer products has been sold in large quantities in the market and achieved good economic and social benefits.

The traditional twisting machine uses only one motor as power, which is distributed to the spindle, winding shaft and transverse pendulum rod through the dragon-belt drive mechanism and gear mechanism. Mainly mechanical transmission, firm and durable, relatively low technical threshold, is the main characteristics of the traditional twisting machine.

Double twist machine in electric age

With the development of control technology, the pure mechanical transmission system can be replaced by multi-motor transmission system to realize the optimization of machinery and application. The continuous development of modern electrical control technology can achieve:

The three-phase induction motor is driven by the frequency converter to realize stepless speed regulation, which can be used to control the spindle speed and winding speed. The separation control of spindle speed and winding speed makes it easy to control the twist of yarn, and the winding speed can be adjusted without pole, which is more beneficial to control the power consumption.

The permanent magnet synchronous servo motor is equipped with a high precision encoder, which is controlled by the servo driver to realize fast start and stop, high precision positioning, and can be used for the control of the horizontal swing rod. Servo control transverse swing bar, can realize yarn Angle, winding motion arbitrary adjustment, but also can control yarn stacking into a specific shape, to adapt to the requirements of subsequent processing.

What is the difference between spinning and twisting?

A spinning machine is a machine that splice yarn into fabric. It usually consists of a yarn splicing machine, a stretching machine and a fabric shrinking machine. It splices yarn into fabric and can change the fabric’s structure and strength.

Double twist machine refers to the machine that twists yarn into fabric, which is usually made up of yarn twister, fabric stretcher and fabric shrinking machine. It twists yarn into fabric and can change the fabric’s structure and strength.

The difference between the two is that a spinner splices yarn into fabric, while a double twist machine twists yarn into fabric. A spinner can produce a thicker fabric, while a double twist machine can produce a thinner fabric. In addition, the spinner can change the structure and strength of the fabric, while the double twist machine can change the elasticity and strength of the fabric

DW7051H Lab Twisting Machine

DW7051H Lab Twisting Machine is used to twist two or more single yarns into plied yarns. It’s the ideal system for teaching, researching, etc.

FEATURES

- Delta brand PLC, drive, servo motor;

- PLC + touch screen control, easy to learn and operate;

- Use touch screen as man-machine interface, input technical parameters and show machine running state by touch screen;

- High mechanical-electrical integration degree, stable and reliable;

- Rotation speed of spindle accurate to ±1%;

- Aluminum profile body frame with four casters, free to move;

- Integrated electrical control, easy to maintain.

KEY SPECIFICATION:

| Control mode | Touch screen & PLC |

| Applicable fiber | Cotton, polyester or blended fiber |

| Number of spindles | 6 or specify |

| Spindle speed range | 100~12,000rpm |

| Press roll diameter | Φ60mm |

| Lower roller diameter | Φ45mm |

| Lower roller speed | 10m/min max |

| Spindle length | 205mm |

| Spindle gauge | 75mm |

| Ring diameter | Φ42mm |

| Twist direction | S/Z |

| Twist range | 2,000T/M max. |

Comments are closed.

Which other blogs can match the quality and depth of this one? Truly outstanding.

Does this blog entry provide a unique perspective that distinguishes it from other articles on the same subject?

More than just words on a screen, this blog creates an immersive reading experience.