What is Ring Spinning Machine? How does laboratory Ring Spinning Machine work ?

Contents

Ring Spinning Machine

Ring spinning machine is a spinning machine that draws, rewinds, or rolls half-finished roving or sliver into a fine yarn.

The roving is made of fine yarn through the drafting of the fine gauze machine and by the drawing and holding of the roving machine. It can be made into fine yarn by the drafting and tenting of the fine gauze machine; the roving and tenting of the roving yarn can be made into fine yarn by the drawing and tenting of the fine gauze machine; the combing machine can comb the fibers into fine comb strips; the needle combing machine can combine the strips together.

Ring spinning machine is the main machine of spinning, the output and quality of spinning is a comprehensive reflection of the advantages and disadvantages of each process of spinning process.

Our DW7040H fiber spinning machine is mainly for small community mills and textile laboratories

Types of Laboratory Spinning Machine

There are three kinds of Laboratory Spinning Machine such as Frame spinning machine, ;spindle spinning machine and ring spinning machine.

Frame spinning machine and spindle spinning machine belong to intermittent spinning machine. Ring spinning machine belongs to continuous spinning machine.

There are some differences in the way of spinning of these three roving spinning frame, and there are also many differences in performance.

According to the relevant studies, the uniformity of the ring spinning frame in these three spinning machines is relatively lower than that of the first two but the spinning frame.

Specifications of mini spinning machine for Textile Spinning

Specification of laboratory spinning machine is described below

| Control mode | Touch screen & PLC |

|---|---|

| Number of spindles | 6 |

| Applicable fiber length | 22~50mm |

| Draft range | 10~50 |

| Draft control | Automatic |

| Roller diameter | Front roller: Φ25mm, middle roller: Φ25mm, back roller: Φ25mm |

| Center distance of rollers | Front and middle: 43mm Front and back: 143mm |

| Pressure mode | Spring cradle |

| Twist settable range | 200~2000 twist/m |

| Twist direction | S or Z |

| Max. speed of spindle | 12,000rpm |

| Spindle gauge | 70mm |

| Spindle length | 205mm |

| Ring diameter | Φ42mm |

| Yarn density range | 6~99tex (6~100Ne) |

| Capacity | Approx. 0.25~1kg/h |

| Power supply | AC220V, 50Hz |

Small yarn spinning machine Features

- Use S/Z twist turning;

- Delta brand PLC, drive, servo motor;

- Rotation speed of spindle accurateto ±1%;

- Aluminum profile body framewith four casters, free to move;

- Modularindependent drive for drafting, spindle blade and flyer;

- PLC + touch screencontrol, easy to learn and operate;

- Use touch screen as man-machine interface, input technical parametersand show machine running state by touch screen;

- Multi-functionaldesign, easy to clean, set and maintain.

Application of laboratory spinning machine and theory

Lab Ring Spinning Frame is used to spin roving to be spun yarn through drafting and ring spinning. It’s the ideal system for teaching, researching, etc.

Fiber spinning machine is mainly composed of feeding mechanism, drafting mechanism, loading mechanism and winding mechanism. The function of the feeding mechanism is to draw out the roving or strips and feed them to the drafting mechanism. The drawn whisker is output by the front roller, and is wound around the yarn tube after it is added into a fine yarn. The drafting, loading and winding of most spinning machines are continuous. They are called ring spinning machines, respectively, according to the different winding mechanisms used.

How does lab spinning machine work ?

Installation and Wiring

For the sake of system security and normal operation of this machine, you must read these instructions before installation.

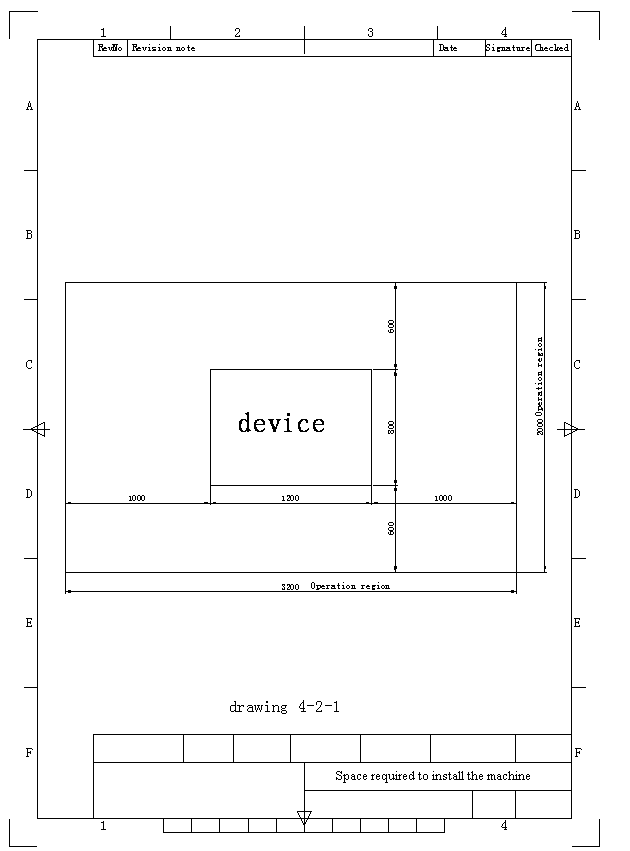

Environment required to install the machine must meet requirements as below:

- Dry place, no drips, steam or oily dust;

- No corrosive, flammable gas or liquid;

- Solid base and no vibration;

- No electromagnetism and noise;

- To minimize electrostatic charge, it is much better if constant temperature & humidity room, 28℃;

Electrical wiring must follow regulations as below:

- In order to ensure safety, once the wiring specifications is selected, please follow the electrical wiring regulations to implement;

- The machine must be separately grounded. It is best not to ground with other equipment. (We recommend using two metal rods about 2 meters that 2.5meters far away hit into the ground, who’s upper connected with a wire and then connected to the ground terminal of the machine.

Operation and Clean

One month after the initial installed, we should check all operating

parts, adjust the belt tension, check the roller bearings and fasten screws. Each half a year later, we must check roller bearings, replace spindles and other lubricants, adjust the belt tension and change worn components.

Requirements: switch power supply, cut off the preamp power and hang repair notices (power, equipment).

If you need more information about Ring Spinning Machine and small wool spinning machine price and theory , please send email to [email protected].

Comments are closed.

Thanks for sharing.Does this Ring spinning machine suit for Univeristy . If possible you can send email to me

Oh my goodness! Amazing article dude! Thanks