History of Cotton Spinning Machine

Cotton spinning machine is defined as machines that process (or spin) prepared cotton roving into useable yarn or thread. The followings are the history of cotton spinning machine.

Contents

Early spinning tools

The first spinning tools were quite basic, consisting merely of a spindle and a winding rod. The loose fibers are twisted into yarn by spinning the spindle like a top, which is then coiled on a winding rod. The Indians developed this crude instrument and turned it into a spinning wheel, which replaced the hand spinning spindle with technology, but only one yarn could be produced.

Spinning wheel

In 1030, the Islamic world created the spinning wheel. It later spread to China around 1090, and then to Europe and India in the 13th century via the Islamic world.

All spinning was done by hand using spinning wheels until the 1740s. The Jersey wheel was the most sophisticated spinning wheel in Britain, but as an alternative, the Saxon wheel was a double-belt treaded spinning wheel in which the spindle spun faster than the traveler in an 8:6 ratio, employing both fingers.

Spinning jenny

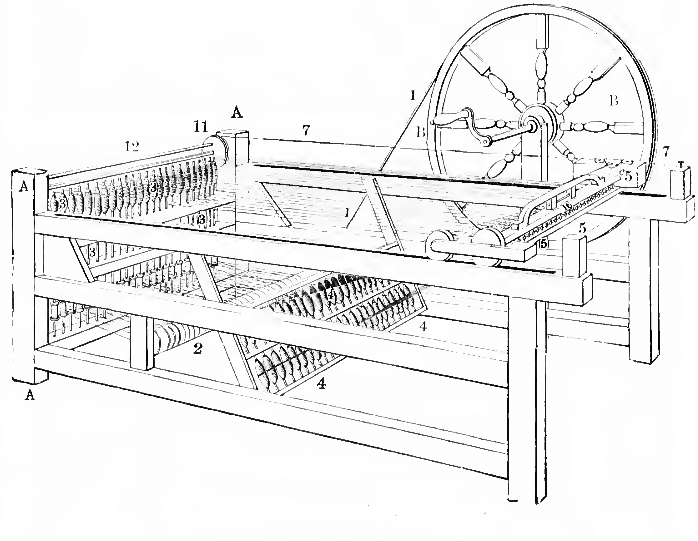

The contemporary spinning machine debuted in England. Hargreaves and his wife, British weavers, were working at home one day in 1764, one spinning and the other weaving. They utilized hand spinning wheels back then. Hargreaves accidently toppled over the spinning wheel and saw that the spindle had altered from horizontal to upright, yet it continued to spin. This phenomenon got Hargreaves thinking: Since the spindle can rotate vertically, wouldn’t it be feasible to spin numerous yarns if several spindles were turned side by side at the same time?

So Hargreaves built it himself from his own design. A spinning machine with 4 wooden legs, a rotating shaft under the machine, sliding rails on the machine, and 8 vertical spindles was ultimately created after several testing and upgrades.

Hargreaves christened the new machine “Jenny” after his adored daughter. Following that, the number of spindles was steadily raised from 8 to 18, 30, and 80, and the efficiency was substantially enhanced. The “Spinning Jenny” was immediately adopted by other firms, thereby solving the “yarn crisis” that had previously plagued the British textile industry. The creation of the “spinning jenny” is significant in cotton spinning machine history. It was dubbed “the first innovation that substantially improved the conditions of British laborers” by Engels.

Water frame

In 1769, the British inventor Charles Arkwright patented the “hydraulic spinning machine,” which was powered by a water wheel to revolve the belt. The roving is attenuated (pulled) and twisted by wrapping it around a spindle. It is a massive, heavy machine that requires power and was known as a waterwheel in the late 1800s. The “Water Spinning Machine” outperforms the “Spinning Jenny” in terms of efficiency and yields a stronger and more compact yarn.

Spinning mule

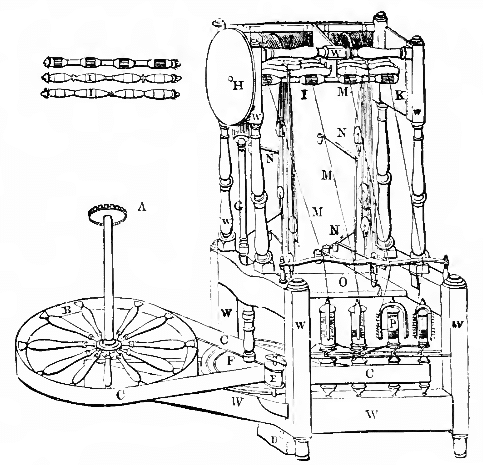

Crompton created the spinning mule in 1779. Crompton is an Englishman as well. He has worked as a textile worker and utilized the “spinning jenny” and is familiar with its drawbacks. After several years of arduous investigation, Crompton eventually constructed the “mule spinning machine”. Because it possesses the benefits of both “Jenny spinning machine” and “hydraulic spinning machine”. The British jokingly termed it “the mule”, and subsequently named it “the mule machine”. The “Mule Machine” spun thin, durable yarn that was widely utilized in textile mills at the time.

It is so named because it is a hybrid of these two machines. The mule consists of a stationary frame containing a creel containing the roving, connected by a headstock to parallel supports containing the spindles. It uses an intermittent process: In the outward traverse, the roving is released and twisted. And in the return traverse, the roving is clamped, the spindle reverses, and the newly spun yarn is taken up.

Throstle

The Throstle frame is related to the Water frame. It operates on the same principles, but is more elegantly constructed and driven by steam. The Danforth throttle frame was created in the United States in 1828. The hefty flyer vibrates the spindle, and the yarn winds up every time the frame pauses, but without success.

Ring spinning machine

The “ring spinning machine” was created in 1828 by Americans. The roving is supplied into this machine by spinning drums, which pull it into finer yarns, which are subsequently twisted into bobbins by rotating travelers. In the current spinning business, the “ring spinning process” is widely utilized. The ring spinning machine has a very large scale; each machine can contain up to 500 spindles, the spindle speed reaches 2000 revolutions per minute. And the bobbin may be replaced automatically once it is full, resulting in a very fast production speed.

Open-end spinning

Open-end spinning is a method of producing yarn without using spindles. It was conceived and developed at the Cotton Research Institute in Ústí nad Orlicí, Czechoslovakia, in 1963. It is also known as break spinning or rotor spinning.

DREF friction spinning

Friction spinning, also known as Dref spinning, is a textile process used for spinning coarse counts of yarns as well as sophisticated core-wrapped yarns. Dr. Ernst Fehrer invented the technique in 1975. He had begun work on the development of this alternative to mule, ring and rotor open end spinning with the objective of surmounting the physico-mechanical limits on capacity in yarn engineering, enhancing the production speeds.

Dref yarns are thick and have a low tensile strength, making them ideal for blankets and mop yarns. They may be spun from asbestos or carbon fibers, and they can be used to produce filters for water systems. This process may be used to spin yarns such as Rayon and Kevlar.

There are three main technologies for spinning fibers in use today:

- Roving spinning, which employs twentieth-century ring-spinning technology,

- For high quality threads, open end, rotor, or break spinning is employed.

- For other yarns, use friction spinning.

Friction spinning is the quickest of these processes, but the yarn is uneven and thicker, making it only suited for certain uses.

Thank you for another excellent piece. Where else could somebody receive that amount of knowledge presented in such a flawless manner?