What is Laboratory Carding Machine? How does lab carding machine work ?

Contents

Laboratory Carding Machine

Laboratory Carding Machine of Spinning is used to comb loose fibers cleaned and opened through the previous opener to produce sliver in cotton spinning mill. Carding machine is used for processing cotton fiber and chemical fiber, belonging to textile machinery. According to the spinning process, carding is an important process. The former process of the carding machine is to open the cleaning cotton combination machine. And the latter process is the drawing machine (general combing process flow) or the strip winding machine (combing process flow).

Our DW7010 Laboratory Carding Machine is mainly for for small community mills and textile laboratories

Types of Laboratory Carding Machine

There are many kinds of carding machines such as roller carding machines, such as worsted carding machines, woolen carding machines, and carding machines. Take the woolen carding unit as an example. It includes automatic feeding machine, precombing mechanism, 2 ~ 4 section carding machine, bridge mechanism and slitting mechanism. The main one is the carding machine. Automatic feeding machine plays the role of uniform feeding. The precombing mechanism is at the feeding end of the unit, which can loosen and precomb. The cross – bridge mechanism ACTS as mixing and uniformity between the front and rear carding machines. At the output end of the unit, we can divide the slitting net into narrow strips and twisted into roving.

Specifications of Laboratory Carding Machine for Textile Carding

Specification of laboratory carding machine is described below.

| Specifications Name | Specifications Value |

|---|---|

| Control mode | Touch screen & PLC |

| Applicable fiber length | 22~50mm |

| Working width | 260mm |

| Feed quantity | 0.25~0.6kg/h |

| Feed roller diameter | Φ57mm |

| Cylinder size | Φ300mm×260mm |

| Cylinder speed | Max. 600rpm |

| Number of cover plates | 12 |

| Doffer size | Φ160mm×260mm |

| Capacity | Approx. 0.25~1kg/h |

| Can size | Φ250mm×550mm |

| Power supply | AC220V, 50Hz |

| Dimension | 2100×800×1300mm (L×W×H) |

| Weight | Approx. 500kg |

Laboratory Carding Machine Features

High mechanical-electrical integration degree, stable and reliable;

Delta brand PLC + touch screen control, easy to learn and operate;

Use touch screen as man-machine interface, input technical parameters and show machine running state by touch screen;

Aluminum profile body frame with four casters, free to move;

Use standard can coiler to output cotton sliver;

Integrated electrical control, easy to maintain.

Application of Lab carding machine and theory

Lab Carding machine is to use cover plate type or roller type carding machine. With the aid of needle surface movement, to comb the small cotton bundle into a single fiber state, further remove impurities and non-spinnable short fiber. So that the fiber parallel straight, finally made into a cotton strip disc into a cylinder. The self-adjusting and leveling device of carding machine consists of three parts: testing mechanism, control mechanism and executive mechanism.

Testing mechanism

The detection mechanism has two detection points. Under the feeding board, there are two detection mechanisms. The change of the thickness of the cotton layer is transmitted to the controller by changing the displacement sensor into an electrical signal. At the output of the tampon, the thickness of the tampon is measured by a step roller device.

Conteol mechanism

In addition, the controller also detects the speed of the doffer and the feed motor and other relevant signals. The control mechanism adopts 16-bit single-chip microcomputer as the main CPU to ensure high control precision. After sending the sampling signal from the sensor such as the thickness of the cotton layer and the thickness of the cotton stripe to the CPU. The sampling signal will be sent to the actuator through various digital operations. So as to control the speed of the feeding motor and adjust the feeding amount of cotton into the card to achieve the goal of uniform strip weight.

Executive mechanism

The actuator adopts frequency conversion technology. And the frequency converter controls the feeding motor to adjust the speed of feeding roller. It has the advantages of high control precision, rapid response, no temperature drift, zero drift and so on. This control system adopts the control principle of compound loop. Namely, the open loop system composed of cotton layer thickness sensor – controller – actuator is combined with the closed loop system composed of cotton strip thickness sensor – controller – actuator.

How does lab carding machine work ?

Installation and Wiring

For the sake of system security and normal operation of this machine, you must read these instructions before installation. Make sure the wiring is implemented according to the following method.

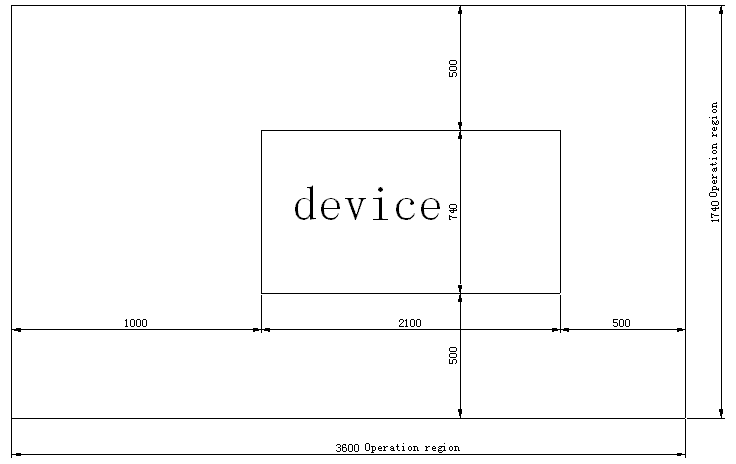

FIG. 1 Space Required to Install the Machine

Environment required to install the machine must meet requirements as below:

- Dry place, no drips, steam or oily dust;

- No corrosive, flammable gas or liquid;

- Solid base and no vibration;

- No electromagnetism and noise;

- To minimize electrostatic charge, it is much better if constant temperature & humidity room, 28℃;

Electrical wiring must follow regulations as below:

- In order to ensure safety, once the wiring specifications is selected. Please follow the electrical wiring regulations to implement;

- The machine must be separately grounded. It is best not to ground with other equipment. (We recommend using two metal rods about 2 meters that 2.5meters far away hit into the ground, who’s upper connected with a wire and then connected to the ground terminal of the machine.

Operation and Clean

- The power supply to the machine is required to be AC220V 50Hz 1200W, please connect the machine to the right power supply, otherwise, it will be harmful to the machine;

- Switch on the main switch and then the touch panel will light and show the screen protection.

Attention

- Please be sure to turn off the power of the machine beforewiring; The power supply to this machine is AC220V 50Hz 1200W;

- Electronic components in the AC motor drivers are particularly sensitive to static electricity, thereforeplease do not put foreign matters into the AC motor driver or touch the main circuit board;

- If thelight of AC motor driver “Charge” still lights after cutting off the power supply. It means AC motor drivers still has high voltage. Please do not touch the main circuit and internal parts;

- In order to ensure the safety of operator and the normal operation of the machine. Please be sure that the machine is properly grounded;

- Do not connect the output terminals U, V, W of AC motor driver to AC power;

- Make sure the driving part of the machine hasno obvious abnormalities as well as drafting part and the spindle part have no yarn and other debris when the equipment is operating.

- There is no debris around the operators.

- Card clothing is exposed and dangerous! Please warn the operators to prevent stabbing hand;

- Operators should not hang the long hair downin order to avoid involvement;

- Clothes of operators should be shut and no accessories like streamerin order to avoid involvement;

- Fiber and staple fiber will produce flyings in the spinning process, so we recommend that use dust removal device in the workshop;

- Don’t use metal wire and old spinning materials;

- Please close the electrical chamber when the machine runs;

If you need more information small carding machine and small wool carding machine price and theory , please send email to [email protected].

I really enjoy simply reading all of your weblogs. Definitely a great post,

Hi, I love reading all your posts. I’d like to write a comment to support you

Thank you for providing this blog to assist. Love the site and all the info!

So happy to find your website! Glad to see more useful blog.

I love your site. It’s always so helpful.

I feel really happy to have seen your webpage and look forward to so many more entertaining times reading here.

I wish more writers of this sort of substance would take the time you did to explore and compose so well. I am exceptionally awed with your vision and knowledge

Your writing is so eloquent and captivating!