Definition and Measurement of Viscosity

Contents

Definition of viscosity

Viscosity refers to the resistance a fluid exhibits to flow. When a fluid (gas or liquid) flows and one part flows over another, it encounters resistance, which is the internal friction of the fluid. To make the fluid flow, a tangential force must be added in the direction of fluid flow to resist the resistance.

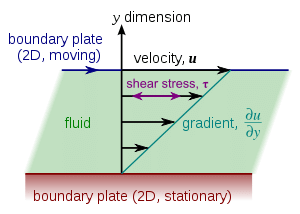

The upper boundary plate moves to the right at a constant speed, causing the liquid below to also move to the right. Since the bottom plate is stationary, the velocity of the liquid gradually decreases from top to bottom, resulting in shear stress inside the liquid. For liquids with low viscosity, the shear stress is small and the internal friction of the liquid is small; for liquids with high viscosity, the shear stress is large and the internal friction of the liquid is large. Therefore, viscosity is defined as the ratio of shear stress to the gradient of the liquid’s horizontal rightward movement velocity in the y-axis direction. In this example, if the distribution gradient of the horizontal rightward velocity of the liquid is fixed, then the viscosity of the liquid is proportional to the shear stress.

Viscosity μ is defined as the ratio of the shear stress to the unit velocity difference of the fluid when the fluid is subjected to shear stress. The mathematical expression is:

τ=μ*∂u/∂y

In the formula:

τ is the shear stress, ∂u/∂y is the velocity gradient along the y direction (perpendicular to the fluid velocity direction), also known as the shear deformation rate; μ is the proportionality constant, that is, the viscosity coefficient, which is equal to when the velocity gradient is one unit, The tangential force experienced by the fluid per unit area.

In the commonly used centimeter·gram·second system, the unit of viscosity coefficient is Poise.

The International System of Units uses Pa·s (1 poise=1 dyne·second/cm2=10-1 Pa·s). For most fluids, the commonly used unit is centipoise cP (10-3 Pa·s).

Measurement of viscosity

There are many ways to measure viscosity, but they fall into two basic methods. An object (such as a sphere or rotor blade) moves through stationary material, or material flows over or past a stationary object. In either case, the resistance to flow is measured.

Various viscometers and rheometers are used to measure viscosity. Rheometers are used when the viscosity of a fluid cannot be defined by a single viscosity value and therefore require more parameter settings and measurements than a viscometer. Closed fluid temperature control is essential for accurate measurements, especially for things like lubricating oil viscosity, which can double with a change of just 5°C. Some fluids have a constant viscosity over a wide range of shear rates (Newtonian fluids). Fluids without constant viscosity (non-viscous fluids) cannot be described by a single number. Non-Newtonian fluids exhibit various correlations between shear stress and shear rate.

At present, the most widely used ones are capillary viscometer, rotational viscometer, falling ball viscometer and cone and plate viscometer. These instruments can measure the viscosity of 10-2 to 1012 poise.

Capillary viscometer

Capillary viscometers, also known as U-tube or glass viscometers, are commonly used in laboratory settings. Viscosity is measured by calculating the time it takes for a clear or translucent fluid to flow between two points in a capillary tube.

Capillary viscometers can be manual or automatic. Automated instruments use infrared optical sensors for transparent samples, or thermal sensors for opaque samples. There are many measurement methods for this viscometer. It can measure the time it takes for a certain volume of liquid to flow through the capillary tube under a certain pressure difference. It can also measure the volume of liquid flowing out under a certain pressure difference per unit time. It can also specify a certain flow rate to measure the capillary tube. The pressure difference between the two ends. The metering pump passes the measured liquid through the capillary tube at a certain flow rate, and then the differential pressure meter measures the pressure difference at both ends of the capillary tube, and the viscosity value can be expressed.

Capillary viscometer has a wide measurement range, high precision, simple and easy maintenance, and can be used at high pressure, but it has high requirements for the cleanliness of the liquid being measured. Suitable for measuring lubricating oil, fuel oil, etc.

Rotational viscometer

A viscometer with a rotational measuring system. It has many types: according to the measurement parameters, it can be divided into torque measurement type (speed does not change) and speed measurement type (torque does not change); according to different device structures, it can be divided into coaxial cylinder type and cone plate type. For a torque-measuring viscometer with a coaxial cylinder structure, when the outer cylinder rotates at a certain speed, the viscosity can be expressed by measuring the torsional moment exerted on the axis of the inner cylinder. It can measure absolute viscosity, is suitable for high temperature and high pressure, and is commonly used in industrial production of chemical fibers, papermaking, resin polymers, etc.

Also known as a Brookfield-type viscometer, a torsion spring is used to measure the torque required to rotate a material’s central axis. Changing the spindle speed and size allows different viscosity ranges to be measured.

Ultrasonic viscometer

It consists of ultrasonic detection components and electronic instruments. There is a shrapnel in its detector. When excited by pulse current, the shrapnel generates mechanical vibration in the ultrasonic range. When the shrapnel is immersed in the sample to be measured, the amplitude of the shrapnel is related to the viscosity and density of the sample. When the density is known, the viscosity value can be obtained from the measured amplitude data. The viscosity of the liquid can be expressed by measuring the attenuation speed of the shrapnel in the liquid by the measuring circuit. The detection element can withstand temperatures up to 300°C, high pressure, and corrosion. Suitable for chemical industry, petroleum, papermaking, rubber, plastics, paint and heavy oil combustion furnace control, etc.

Comments are closed.

Many articles I’ve read in the past have left me feeling confused and overwhelmed, but this one was refreshingly clear and concise.

From the engaging introduction to the insightful conclusion, this blog captures my attention.

I truly appreciate your technique of writing a blog. I added it to my bookmark site list.