What is Fiber Crimp Tester? How does Fiber Crimp Tester work ?

Contents

What is Fiber Crimp Tester

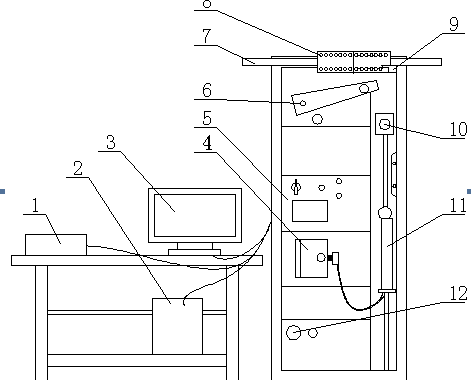

Fiber Crimp Tester FY111F is the latest developed high precision testing apparatus. It is used to automatically measure the crimp ratio, crimp elastic recovery percentage, and number of crimps of the fiber. It adopts the image processing technology to automatically count the number of crimps within the length of 25mm on the fiber sample when the fiber bears the light load, thus it eliminates the uncertainty of manually counted results. With the force sensor the apparatus measures the values of the light load and heavy load that stretch the fiber sample, and measures the fiber lengths when the fiber is under the light load and heavy load respectively, then it calculates the crimp ratio automatically. It also measures the fiber length after the fiber have burdened the heavy load and got relaxed, and then calculates the crimp elastic recovery percentage of the fiber.

The apparatus is finely constructed and is characteristic of fast measurement, precision, high stability, and convenient operation. It’s the ideal system for teaching, researching, etc.

Specification of Fiber Crimp Tester

| Force measurement range | 0~2000 (10-3cN) |

|---|---|

| Force precision | 0.1 (10-3cN) |

| Force error | ≤±1% |

| Gauge between the upper and the lower clamp | 20 mm |

| Lower clamp moving range | 40 mm |

| Length precision | 0.01mm |

| Time set | Auto |

| Count the number of crimps | Auto |

| Length of the fiber within which the number of crimps is counted: | 25mm |

| Power supply | 220V±10% |

How to use Fiber Crimp Tester

Indices

(a) Number of crimps.

It is determined by counting the number of crimps within the length of 25mm on the fiber under the light load.

(b) Crimp ratio.

This index indicates the degree of crimping. It is related with the number of crimps and the convolution height of every crimp. The crimp ratio is calculated by Equation 1.

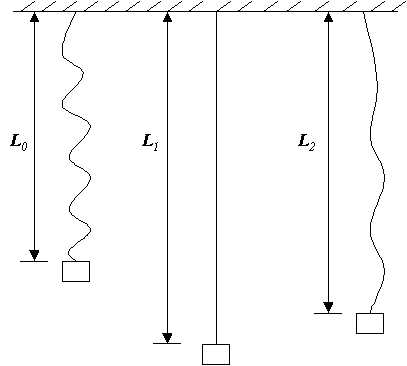

(1)![]()

In this equation:

J - the crimp ratio of the fiber sample (%);

L0 - the measured fiber length under the light load (mm);

L1 - the measured fiber length under the heavy load (mm).

The light load is commonly defined to be 0.0018cN/dtex. The heavy load is 0.05cN/dtex for Vinylon, nylon, polypropylene, and polyvinyl fibers, but for polyester and acrylic fibers, it is set to be 0.075cN/dtex.

(c) Crimp recovery ratio.

The crimp recovery ratio indicates the crimp recovery ability of a fiber when it is unloaded. It reflects the crimp stability of the fiber. This index is defined by Equation 2.

(2)![]()

In this equation, Jw - the crimp recovery ratio of the fiber sample (%);

L2 - the measured fiber length under the light load after it has borne the heavy load for 30 seconds and relaxed for 2 minutes (mm).

(d) Crimp elastic recovery percentage.

The crimp elastic recovery percentage is defined as

(3)![]()

In this equation, Jd - the crimp elastic recovery percentage of the fiber sample (%).

Figure 1 presents the fiber length due to the variation of crimps under different conditions.

Working principle

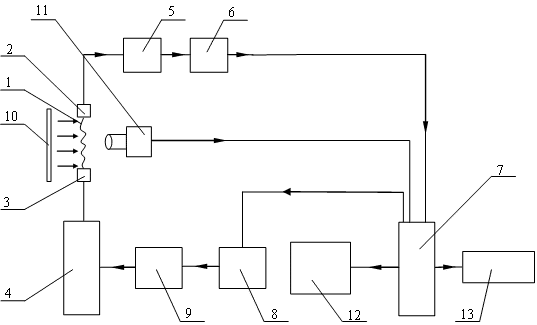

The working principle of the apparatus is illustrated in Figure 2.

In Figure 2, the fiber sample 1 is clamped loose between the upper clamp 2 and lower clamp 3. When the test begins, the computer 7 produces pulses, which drive the transmission system 4 through the pulse-distributor, driver 8 and step motor 9, and finally make the lower clamp 3 to move downward and stretch the fiber. The force sensor 5 measures the value of the tensile force of the fiber, which is then transmitted to the computer 7 through the amplifier 6. When the measured force value reaches the predefined light load value, the fiber length is caught automatically as the initial length L0 of the fiber. At the same time, the image measuring system, which is constructed by the CCD camera 11, luminous installation 10, computer 7, and monitor 12, displays the image of the fiber crimps and counts the number of crimps automatically.

The lower clamp 3 continues to descend and draw the fiber, and the force sensor 5 measures the tensile force of the fiber. When the force value reaches the predefined heavy load value, the lower clamp stops moving and the apparatus automatically catches the fiber length as the uncrimping length L1. Then the crimp ratio is calculated automatically by L0 and L1 according to Equation 1. The lower clamp keeps stationary for 30 seconds making the fiber bearing the heavy load during this time, and then rises to its initial position. After the fiber have rested for 2 minutes, the lower clamp descends again till the tensile force of the fiber reaches the light load value, then the fiber length is caught automatically as the recovery length L2. Therefore, the crimp elastic recovery percentage can be calculated automatically by L0 , L1 , and L2. At last, the measured results can be printed by the printer 13.

If you need more fiber Crimp Tester price and theory, please send email [email protected].

Comments are closed.

Thanks for the information, keep sharing this type of info.

This is the finest article I’ve read in a long time.