What is small dyeing test knitting machine? How does small dyeing test knitting machine work ?

Contents

What is small dyeing test knitting machine?

Dyeing test knitting machine,also named Small fabric knitting machine. It is the first choice equipment for the laboratory of chemical fiber spinning factory, dyeing factory and weaving factory to distinguish yarn color difference, grade and ensure dyeing uniformity. It is suitable for many kinds of chemical fibers(20-1000dtex).

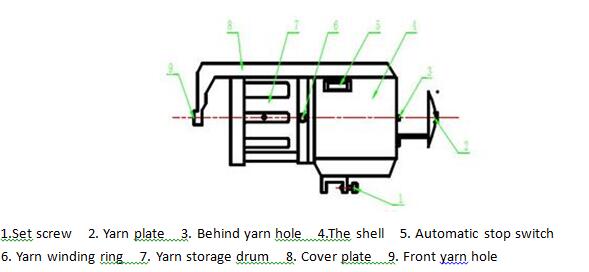

The structure and function of dyeing test knitting machine

The overall structure of dyeing test knitting machine is mainly divided into five parts: frame, storage yarn, weaving, pulling and control.

Storage yarn part

Weft feeder wind the yarn from the yarn spindle to the yarn drum.

Weaving part

The knitting needle cooperate with sinker to make into a circular weft knitting yarn.

Pull part

The most advanced continuous pull institutions pull the knitting into knitting fabric storage box.

Control part

The computer control the machine after accepting instructions.

The performance feature of the machine

Real and reliable data

This machine adopts the active storage and transmission yarn device (referred to as the storage weft device or weft feeder).And we use the imported technology to produce it.In which has achieved the semi-activation in delivering lines, and the yarn tension of the input textile head is small and stable.

The influence of tension fluctuation on uniformity of the fabric density in the process of yarn winding is eliminated, avoiding errors in color judgment, and ensuring the authenticity of dyeing test.

Precise time control

There is a digital electronic time relay controls each sampling time. And the sampling time (i.e. fabric length) can be adjusted any time directly and arbitrarily (which can be accurate to1/10 second), so that each fabric length can be accurate to 1 mm.

Stable system

It adopts the soft adjustable Laura system for the new knitter.We equipped it with a 60KTYZ claw-type Youngs synchronous motor with 3.5.8.5 per min.Which not only makes the whole set of Laura operate stably without any noises, but also suitable for weaving and density adjustment of any fiber yarn.And ensure the machine is always at its best.

simple operation

Control the machine the button on electrically control board. Meanwhile,there is a click-starting button on the stop-button to facilitate users.

Operating steps

Threading order

Use thread hook to pass yarn through winding ring 6 and out of behind yarn hole 3, hook yarn on yarn barrel, pull out thread hook from yarn winding 6. After that, press yarn on storage drum 7. Then press yellow button on control panel to wrap yarn on storage drum and pass yarn through front yarn hole 9.

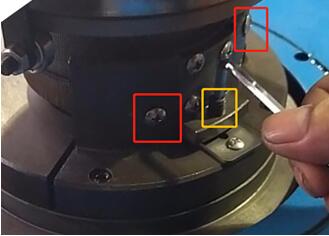

Adjusting fabric density

Loosen the screws in the red frame with a screwdriver . Then adjust the screws in the yellow frame with an inner hexagon wrench. Loosen the fabric density by rotating the screws counterclockwise and tighten the fabric density by rotating the screws clockwise. The last step ,ighten the screws inside the red box after adjustment.

If you need more information about Small fabric knitting machine. Or the price of dyeing test knitting machine, please send email to [email protected].

Comments are closed.

They consistently deliver high-quality content that keeps readers coming back for more.