Introduction of Fiber Length and Measurement

Fiber length directly affects the processing performance and practical value of the fiber and reflects the quality and performance of the fiber itself, so it is one of the most important indicators of the fiber.

Contents

Fiber length definition

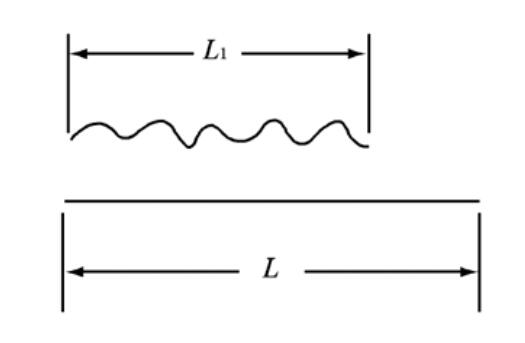

Natural length: All kinds of fibers have different degrees of bending or crimping in the natural stretch state, and its projected length is called the natural length.

The length of a fiber in a fully stretched state is called the stretched length.

Common fiber length ranges

The length of natural fibers is affected by the variety and growth conditions: the length of cotton fibers is short, fine-staple cotton is generally less than 33mm, long-staple cotton is generally less than 50mm, and the length of longer than 50mm is ultra-long-staple cotton; the length of wool is longer, generally more than 50mm, the longest Up to 300mm.

The cutting length of chemical fiber shall be determined according to the type of processing machine and the length of the fiber blended with it: cotton-type chemical fiber, wool-type chemical fiber, medium-length chemical fiber (for processing wool-like products).

Fiber length index

There are two types of fiber length indexes: centralized indexes and discrete indexes. The concentration index represents the average nature of the fiber length, and the discrete index represents the unevenness of the fiber length.

Concentration Index

Average Length: Refers to the average length of a bundle of fiber samples. According to different test methods, it can be divided into counting weighted average length, weighted weighted average length and harmonic average length. Mainly used for wool, hemp, silk and chemical staple fibers.

Main body length: refers to the length of a group of fibers with the largest number or mass in a bundle of fiber samples, which is called counting or weighting main body length.

Staple Length: Staple Length is the cotton fiber length measured by hand-pulling ruler measurement method in the visual inspection method of hand feeling.

Span Length: The span length is the fiber length index measured by the photometer. The determination of this index is to quickly measure the fiber length and length uniformity by using the characteristic that the light transmission amount of the fiber protruding from the comb is a function of the light shading amount of the fiber layer.

Inhomogeneity index

Length Coefficient of Variation: The Fiber Length Coefficient of Variation is often used to assess the degree of variability in data after averaging measurements from a study subject. It is obtained by comparing the standard deviation with the mean. In a nutshell, the fiber length coefficient of variation expresses the degree of variation of each variable in the data set relative to the mean size.

Length uniformity: generally refers to the ratio of the average length of the count to the average length above the average length of the count (the average length of the upper half).

Fiber length test method

Hand pull visual method

- Fast inspection speed and simple measurement

- For cotton fiber, the resulting length is close to the main length of the fiber, and the maturity and strength of raw cotton can be estimated visually by hand.

- Influenced by subjective factors, the inspection operation method of the grader must be checked regularly according to the standard cotton sample.

Instrument inspection

(1) Measurement of the length of a single fiber.

(2) Arrange the fiber sample into a fiber bundle with one end even, make a fiber arrangement distribution map and fiber length distribution or carry out length group weighing, and obtain various length indicators.

(3) Randomly clamp the fiber sample bundle, measure the relationship between the fiber amount and the length of the extended clamping line, and obtain the camera curve.

Single fiber length measurement

The method of stretching the fiber one by one and measuring its single length. It takes more time, but the measurement result is accurate, and the distribution of fiber length and number can be obtained.

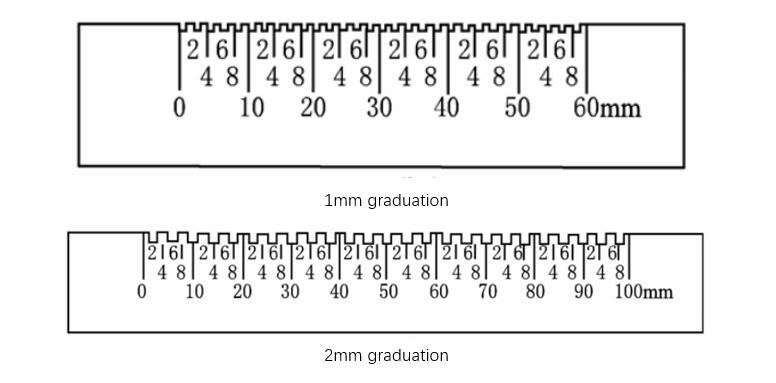

Oil-glass method

On the graduated glass plate, apply a layer of paraffin oil evenly, and line it with a black or wool board that is in contrast to the color of the fiber. After the fiber is tensioned and stretched, it adheres to the glass plate due to the effect of wax oil, and remains in a straight state. When the fiber is moved to an appropriate position, the length of the fiber can be read on the scale of the glass plate. Suitable for finer fibers below 2dtex.

Toothed scale method

With two normally closed tweezers, the jaws open when the hand is pressed, and the width of the jaws does not exceed 0.5mm. Place a single fiber on a fleece of a color that contrasts with the fiber, and hold one end of the fiber with one pair of tweezers while holding the other end of the fiber with another pair of tweezers. When gripping, make sure that both ends of the fiber are just visible beyond the jaws of the tweezers. Align the fiber exposed end of the tweezers held by the left hand with the zero line of the length scale, and hold the tweezers with the right hand to pull the fiber until the crimp disappears. Then place the right-hand tweezers on the fiber end point. Read the fiber length on a length ruler.

Instrument method

Automatic measurement of fiber length with a dedicated single fiber length measuring instrument.

Fiber length measurement

The fibers are sorted into straight and parallel fiber bundles with one end flat, and then grouped and weighed according to a certain length group interval to obtain various length indexes of the fibers.

Comb Fiber Length Measuring Instrument

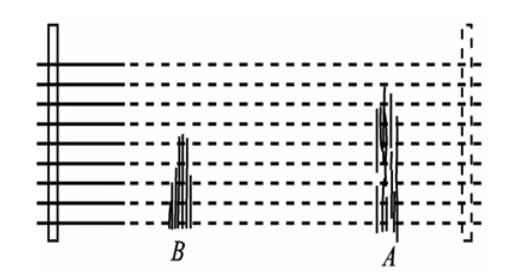

Put the straight fiber bundles on the comb, press the fork to press the fiber bundles into the comb needles, pull out part of the fibers from the exposed end one by one, stack them on the other end of the comb, and make a fiber bundle with one end even.

Roller Length Measuring Instrument

The roller-type fiber length tester measures the length of cotton fibers in groups according to the distribution characteristics of fiber length. Long and short fibers are controlled with the help of roller nippers and grouped and isometric gravimetric tests are performed. During the test, the fiber bundle of the sample should be pretreated so that one end is trimmed, and then clamped with rolling clamps. As the drum rotates, short fibers come out first, followed by long fibers. Weight measurements will be made against these individual fiber groups. Through data calculation, data such as fiber length distribution, main part length, qualified length, average length, base number, and short fiber uniformity can be obtained.

Photoelectric fiber length camera

KX730 fibrograph adopts photoelectric method to accurately and quickly measure the average length, upper half average length and evenness index of cotton fiber samples. The instrument is designed according to the theory of random distribution of cotton fiber length and the theory that the light intensity passing through the fiber bundle is negatively correlated with the number of fibers in the cross section of the fiber bundle.

Comments are closed.

How I wish I had stumbled upon this blog sooner! The quality of the content is unparalleled, providing a rich tapestry of information and inspiration that leaves a lasting impact.

Too often, important discussions like the one initiated by this blog post are silenced or ignored.

Join the ranks of those who have been enlightened by this article. You’ll come away with a wealth of knowledge and a thirst for more.

As a reader, I feel lucky to have stumbled upon this article. It satisfied my curiosity and left me with a lot of new knowledge.