Bursting Strength Test and Related Equipment

When fabrics are worn or used, they are often subject to concentrated loads perpendicular to the plane of the fabric. The fabric bulges and expands from one side until it breaks, such as at knees, elbows, shoe uppers, glove fingers, and sock toes. This phenomenon is called bursting or bursting. Since its force mode is multi-directional force damage, this test is particularly suitable for knitted fabrics, three-way fabrics, non-woven fabrics and parachute fabrics.

Contents

Basic principles of bursting performance testing

(1) Steel ball method: A sample of a certain area is clamped in a circular sample clamp on a fixed base. The spherical ejector pin vertically pushes against the sample at a constant moving speed, causing the sample to deform until it breaks. The bursting strength was measured.

(2) Hydraulic method: Clamp a sample of a certain area on an extendable diaphragm, and apply liquid pressure below the diaphragm. Then, the volume of the liquid is increased at a constant speed to expand the diaphragm and the sample until the sample ruptures, and the bursting strength and bursting expansion are measured. The test sample is ruptured by hydraulic pressure acting on the rubber eardrum. It is used to test the maximum pressure value and bursting height of knitted, woven, paper, and cardboard paper when they rupture.

(3) Air pressure method: Clamp the sample on an extendable diaphragm, and apply gas pressure under the diaphragm. Then, the gas volume is increased at a constant speed to expand the diaphragm and the sample until the sample ruptures, and the bursting strength and bursting expansion are measured.

Experiment procedure

Steel ball method test steps

(1) Install the spherical ejector rod and holder, ensuring that the center of the ring holder is on the axis of the ejector rod.

(2) Place the sample into the ring holder and clamp it, with the reverse side of the sample facing the ejector pin. Then place the ring holder into the test slot on the stand.

(3) Start the tester until the sample is broken.

(4) Record the maximum bursting strength.

Hydraulic method test procedures

(1) Clamp the circular sample on the extensible diaphragm so that it is flat and without deformation. Clamp with clamping ring Sample.Clamp the round specimen on the extensible diaphragm so that it is flat and without deformation. Clamp the specimen with clamping rings.

(2) Start the tester to expand the diaphragm and sample. Until the sample breaks, the bursting strength and bursting expansion are measured. This step is basically the same as the air pressure method.

(3) Repeat the test on different parts of the fabric, and achieve at least 5 tests on each part.

(4) The measurement of diaphragm pressure is the same as the air pressure method.

Air pressure method test steps

(1) First place the circular sample on the elastic diaphragm and clamp it between the semicircular cover and the chassis. Then adjust the expansion recording device to the zero position and tighten the safety cover as required.

(2) Start the tester and test the samples one by one. After the samples are damaged, measure the bursting strength and bursting expansion.

(3) Reset the tester and repeat the above steps until the specified number of samples is completed.

(4) Test the correction coefficient of the elastic diaphragm. Use the same airflow speed as the above test, clamp the elastic diaphragm with a clamp without a sample, and make the diaphragm expand to the pressure required when the average burst expansion of the above sample is reached, which is the correction of the elastic diaphragm. coefficient.

Bursting strength tester

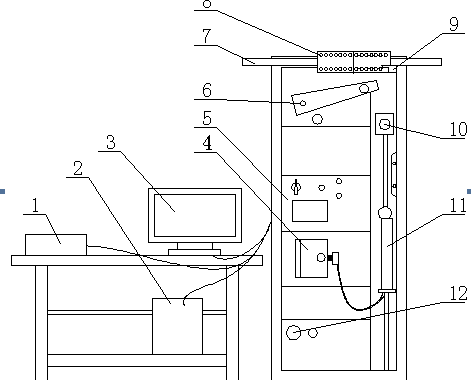

Bursting Strength Machine YG032D

Bursting Strength Machine is used for testing fabric bursting strength and expansion such as knitted fabrics, non-woven fabrics, leather etc.

Bursting Strength Machine Method: The sample is held at an extension on the diaphragm, below the diaphragm pressure (manual liquid pressure, electric liquid pressure, gas pressure, etc.), making the diaphragm and sample expansion, increasing the pressure at a constant speed, until the broken sample is measured for burst strength or burst expansion ratio.

Following are the Fabric Burst Strength Test features:

- Large touch panel with concise and clear menu, easy to operate;

- Special tooth profile clamps ensure the sample not slip;

- Manual gripping device;

- High quality and renewable rubber diaphragms, durable in use;

- Print the test reports by a built-in micro-printer;

- Comprehensive and detailed test results.

Digital hydraulic bursting strength tester YG032M

YG032M digital hydraulic bursting strength tester is used to measure the bursting strength and bursting expansion of various materials, including textiles (knitted and woven), non-woven fabrics, paper, plastics, medical products, etc.

Follows are Bursting Strength Tester features :

- Touch screen with concise and intuitive interface, simple and convenient to use;

- Transparent organic glass cover with blue lamp lighting, the light is soft and bright, easy to observe the test process;

- Non-contact laser ranging with high accuracy measurement, sensitive and fast response, the ranging system is stable, durable and reliable;

- The magnetic suction mode makes it quick, simple and convenient to change the test heads of different test areas;

- The intelligent identification function can remind operators to confirm whether the installed test head matches the test area to prevent test failure or serious deviation in test results;

- Pneumatic clamping sample, the force is uniform and no slippage, the operation is safe and convenient;

- Four test methods are available: CRB, CTB, CE, CP;

- Security design: The equipment will stop measuring and display over range pop-up when the bursting pressure or height value over the range;

- With data storage (20 groups, each group of 20 samples), query and print functions;

- Equipped with calibration kit, easy to calibrate the height.

Pneumatic bursting strength tester YG032P

Pneumatic bursting strength tester is used for the air pressure method of various fabrics, including knitted fabrics, woven fabrics, non-woven fabrics, laminated fabrics and other fabrics made by processes, and can obtain the bursting expansion or bursting strength under standard conditions.

Factors affecting the bursting strength of fabrics

The internal factors of the fabric itself

The influence of the breaking strength and breaking elongation of the yarn. When the breaking strength and elongation of the yarn in the fabric are large, the bursting strength of the fabric is high.

The influence of fabric thickness. Under other conditions being the same, when the fabric is thick, the bursting strength is greater.

When other conditions are the same and the warp and weft densities of the fabric are different, the fabric will tear in the direction of smaller density when bursting. The tear will be linear and the bursting strength of the fabric will be low.

Influence of external factors

- The impact of testing methods.

Using different testing methods, the test results will also be affected. Generally speaking, the bursting strength measured by the hydraulic method and the pneumatic method is much more stable than that measured by the steel ball method.

- The impact of the test environment.

- The influence of the operator.

Leave a Reply

You must be logged in to post a comment.

All readers will appreciate the well-organized structure and user-friendly interface of this blog.

Readers will find themselves immersed in the captivating narratives and thought-provoking content.

More than just information, this blog provides thought-provoking insights.