Temperature in Weathering Test: Measurement & Calibration

Contents

Introduction

The materials and products commonly used in our daily lives, such as textiles, plastics, leather, coatings, building materials, etc., will age over time due to comprehensive damage caused by factors such as light exposure, heat and cold, wind and rain, bacteria, etc. These factors work together to cause chemical and physical microscopic changes in materials, such as discoloration, reduced strength, structural damage, etc. This process is called weathering. The ability of a material to resist these damages is called weathering property.

Why is Temperature in Weathering Test So Important?

In the actual research and producing process, in order to evaluate the weathering property of a material, the current method is usually to conduct laboratory accelerated weathering tests, mainly simulating the three basic factors of light, temperature, and moisture. Among them, temperature is a key factor affecting the rate of photoaging:

1) An increase in ambient temperature will accelerate the rate of chemical reactions;

2) Weathering is a surface effect, and the performance of the sample, such as color and structure, will affect the surface temperature of the sample, thereby affecting the aging rate;

Chamber Temperature

Measurement of Chamber Temperature

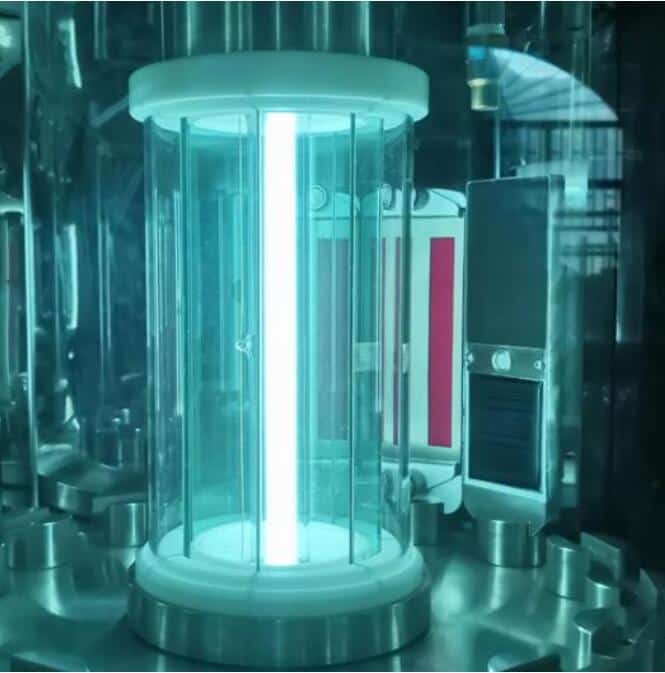

In laboratory accelerated photoaging tests, temperature simulation is divided into chamber temperature and sample surface temperature. Our Xenon Arc Weathering Testers, YG611M (rotating tray type) and YG611F (flat tray type), have a temperature control system mainly composed of a heater, temperature and humidity sensors, BPT/BST, and a controller. During the experiment, the temperature controller, based on the set temperature value, heats the air inside the chamber through heating elements. At the same time, the temperature sensor monitors the temperature inside the chamber in real time and feeds back the temperature signal to the controller. The temperature controller adjusts the power of the heating element based on feedback signals to maintain constant temperature inside the chamber.

The temperature of the test chamber is measured by a temperature and humidity integrated sensor installed on the inner wall of the chamber, and can be displayed in real time on the touch screen.

Calibration of Chamber Temperature

Regarding the chamber temperature, we can choose to calibrate it with a multi probe hygrometer or a small integrated temperature and humidity meter. The specific method is as follows:

1) Hang the three probes of the standard temperature and humidity meter evenly around the circumference of the sample holder, close to the middle of the back of the test clamp but not in direct contact, and avoid direct exposure to xenon arc lamps;

2) Turn on the machine and enter the testing state (only stop the rotation of the sample holder). When the temperature reading of the Xeon Arc Weathering Tester fluctuates slightly around a certain temperature with a regular pattern over time, it is judged to have reached a stable state before testing can begin;

3) Read the temperature value displayed by the Xeon Arc Weathering Tester and the measured values at three positions tb1i,tb2i,tb3i on the temperature calibration meter every 2 minutes, and record them more than 10 times (i=1~10);

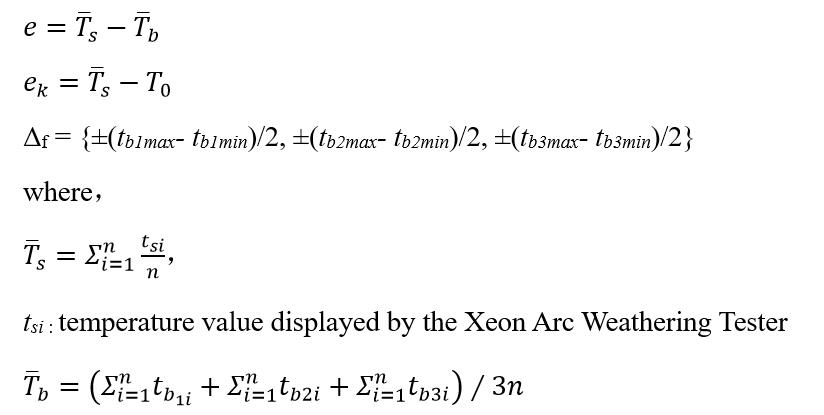

4) Calculate the temperature indication error e, control error ek, and fluctuation Δf of the chamber according to the following formula:

tb1i,tb2i,tb3i :measured values at three positions on the temperature calibration meter

tb1max,tb2max,tb3max : the highest temperature measured n times at three positions of the calibration meter

tb1min,tb2min,tb3min : the lowest temperature measured n times at three positions of the calibration meter

Sample Surface Temperature

Measurement of Sample Surface Temperature

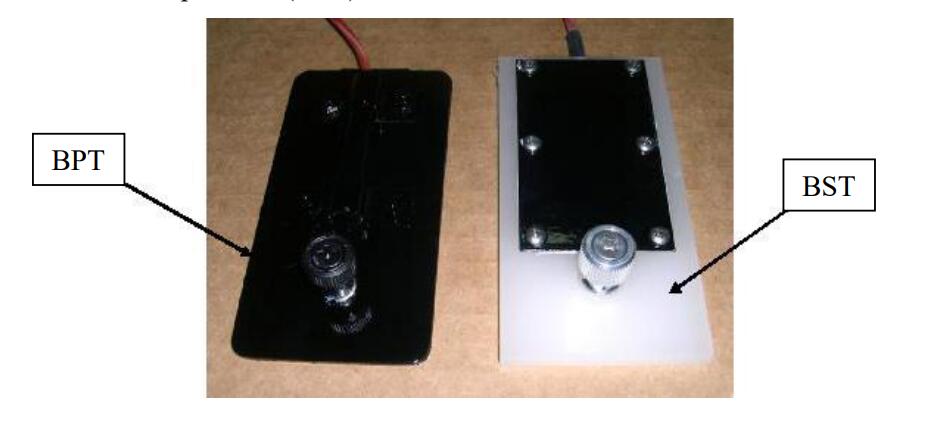

When conducting Xenon Arc Weathering tests and Ultraviolet Aging tests, the surface temperature of the sample is one of the most important aging factors besides irradiance due to radiation. The surface temperature of the sample comes from a complex source. In the Xenon Arc Weathering Tester Chamber, the surface temperature of the sample mainly comes from the heat radiation of the light source, the heat conduction of the air, and the heat transfer of the sample holder. Directly measuring the surface temperature of a sample is both expensive and technically difficult, and is prone to measurement errors. Therefore, people obtain the surface temperature of the sample by measuring the temperature of a BPT (Black Penal Thermometer) or BST (Black Standard Thermometer). The BPT represents the maximum temperature that the sample surface may reach.

A commonly used BPT (Black Penal Thermometer) is composed of a stainless steel plate that is approximately 150mm long, 70mm wide, and 1mm thick. The side of the black panel facing the light source should be coated with a black gloss paint layer that can absorb at least 90% of the total light. The temperature measurement of the black panel is carried out through a black coated rod-shaped bimetallic disk sensor or a resistance sensor likes PT100 located at the center of the panel and firmly connected to the exposed surface.

Calibration of BPT/BST Temperature

1) Standard BPT/BST

Place Standard BPT/BST for calibration adjacent to the BPT or BST of the Xenon Arc Weathering Tester, and the instrument should operate normally. When the BPT or BST temperature reading reaches a stable level, record its reading and compare it directly with the Standard BPT/BST for calibration to calculate the error.

2) Surface temperature thermometer

The method of direct measurement of BPT or BST blackbody temperature is also can be used to calibrate the sample surface temperature. When the BPT or BST reading reaches a stable value, rotate it to the easy to measure position and pause the rotation of the sample holder. Immediately use a surface temperature thermometer to measure the temperature in the middle of the BPT or BST. The difference between the BPT or BST reading and the surface temperature measurement value is the BPT or BST temperature error.

3) Infrared thermometer

Due to its small heat capacity, the traditional contact measurement method causes a significant temperature drop for Black Panel Thermometers or Black Standard Thermometers, so Infrared Thermometers are used for measurement.

- Before use, the emissivity should be adjusted according to the surface condition of the black body of the tested BPT or BST. Refer to the user manual and other relevant materials, and generally adjust it to 0.95;

- The Xenon Arc Weathering Tester is running normally. When the temperature reading on the BPT or BST is stable, it is recorded as Td;

- Pause the machine operation and immediately use an Infrared Thermometer to measure the surface temperature Tb in the middle of the BPT or BST in the chamber;

- Measure twice at the shortest interval, for a total of three sets of data, with the maximum value being Tbmax and the minimum value being Tbmin;

- If the range (Tbmax – Tbmin) is less than 0.5 ℃, then Tbmax is used as the measurement standard value, and the indication error of the black standard thermometer is Td – Tbmax;

- If the range (Tbmax – Tbmin) is greater than 0.5 ℃, it may be due to the infrared thermometer not aligning with the measured object, or the operation delay causing the black label temperature to drop too much, and remeasurement is necessary.

The calibration of BPT or BST temperature can also select multiple temperature points according to the actual situation, and calculate their indication error and control error separately.

Other articles you may be interested in: