Application and development of torque rheometer

Contents

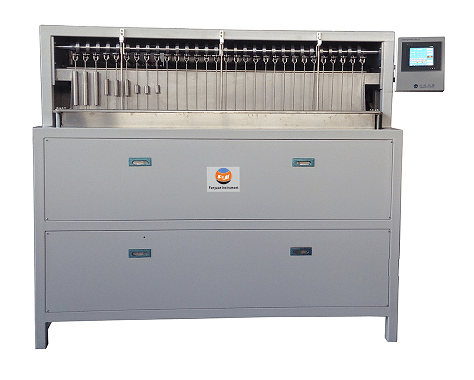

Application of torque rheometer DW5300

Study on rheological properties of polymer

In order to related to the rheological properties of materials between the input (speed) and output (torque, temperature) of the torque rheometer. Rheologists establish a series of mathematical relationships. From the formula, the balance torque and the flow field distribution of the torque rheometer can be calculated.

Inspection of raw materials’

The same polymer has different structures

Homopolymer due to its component. The subchain structure is different from linear, polymer and block structures with long and short branches. The change of rheological properties caused by different contents of the copolymer and the random copolymer. This reaction is reflected in the torque rheometer as the torque changes according to the torsion.

The difference of moment can be used to judge the structure difference of polymer. For example: use intelligent torque flow. The variometer can compare three different structures of polyethylene (high density polyethylene, linear low density). Degree polyethylene, low density polyethylene), also can distinguish natural rubber different origin and so on.

Study on different types of stabilizers

The difference can be studied by using the torque rheometer. The effects of dosage and different types of stabilizers on the processing properties of the polymer were selected. The type of stabilizer and the determination of the best dosage provide the basis.

Process analysis

Typical torque curve

Graft reaction of polymer

The torque curve can be used to study the polymer connection. Through the change of torque over time, whether the grafting reaction occurs or not can be seen. When the reaction begins, when it ends, the amount of reactant used, the proper temperature of the reaction, etc

Factors, therefore, can determine the appropriate processing conditions and a better formulation for the reaction a solid foundation for industrialization.

Study on polymer crosslinking process

Torque curves can be used to study polymers. Crosslinking reactions such as vulcanization of rubber, curing of thermosetting plastics and thermoplastic plastics. The effects of crosslinking and other factors such as type and dosage of crosslinking agent on crosslinking reaction. When the polymer crosslinks, its molecular chain changes from linear to three-dimensional. In the reticular structure, the viscosity of the system increases and the torque increases accordingly, so the torque curve can be adopted. The line rises as a sign of the beginning of the crosslinking reaction.

Study on polymer reaction blending

The torque curve can be used to study the polymer. Through reaction blending, it can be seen whether the two polymers are generated by the curve of torque change with time. Biochemical reaction, when the reaction begins, when the reaction ends, the feed ratio of the polymer, the reverse

The suitable temperature and other factors can determine the coquinone of the two polymer reactions. It is suitable for machining conditions and better ratio to lay a foundation for obtaining high-performance composite materials.

Simulation of rubber refining process

Rubber has a higher molecular weight in processing. Before usually needs to carry on the plastication, reduces the glue material the Mooney viscosity. Use torque rheology. The instrument can simulate rubber’s plastication process and study its influencing factors.

Analysis of PVC gelation process.

The gelation of PVC refers to the flow field. Under the action of force and heat, the resin is gradually melted and plasticized. And then recrystallized to form three – dimensional.The process of spatial network structure. Each layer of granule is contained in the process of PVC gelation.

The fragmentation of the particles, the disappearance of the particle boundary, crystal melting, recrystallization into the macromolecular space Network, entanglement and other complex physical and chemical changes. Through the torque rheology curve. The process of crushing can be analyzed and the model of grinding mechanism can be established.

Development of torque rheometer.

In the early 1990s, the computer controlled torque rheometer replaced the electronic torque rheometer as the main product in the international market. This is because computer participation solved a series of problems such as poor accuracy of experimental results of the torque rheometer and difficulties in analysis of experimental results. The experimental results are affected by severe background noise. Accurate data is hard to come by. However, the computer-controlled torque rheometer can use the powerful function of the computer to instantly smooth out the influence of background noise through the curve smoothing program and automatically mark the characteristic value of the experimental curve. After the experiment, the experimental curve and characteristic value can be printed out from the color printer immediately, which makes the above problems solved.

If you need more information about Torque Rheometer theory or Torque Rheometer testing procedure, please send email to [email protected].

Comments are closed.

A lot of people arе looking round for this information, this post could ɑid them greatly.

I enjoy it for creating the details, keep up the truly amazing article continuing

I can not wait to read much more from you. That is really a great website.