Winch Dyeing Machine: Guide to Feature、Structure and Process

Last updated on April 10, 2025

Contents

Introduction

The winch dyeing machine is mainly used for the winch dyeing of wool fabric, silk fabric, cotton and its blended knitted fabric and chemical fiber simulation fabric. Winch dyeing machine can also be used for scouring and bleaching, soaping and washing of some silk fabrics, cotton and its blended knitted fabrics. This is because these fabrics tend to stretch, chafe and come apart. Dyeing machinery should meet the special requirements of small tension and friction. At present, there are various forms and varieties of this kind of machinery. In general, there are normal temperature and pressure winch dyeing machine, normal temperature and pressure overflow dyeing machine, high temperature and pressure overflow machine, jet dyeing machine and so on.

Winch dyeing machine can be divided into normal temperature and pressure type and high temperature and pressure type. Normal pressure winch dyeing machine is easy to use and is the most commonly used dyeing equipment for cotton knitting.

WE-1 winch dyeing machine is a normal temperature and pressure winch dyeing machine. It is designed for laboratory use of dyeing, boiling off, bleach and washing, etc. processing for all kinds of expensive natural fabric, and knitting fabric or woven fabric of blinding under normal temperature & normal pressure, and also for the application of dyeing and processing for rayon, polyacry-nitrile fiber, and blended fabric under normal temperature & normal pressure.

Winch dyeing machine principle

The fabric is connected from end to end and dipped in the dyeing tank in a relaxed and bent shape,bypassed the cloth guide roller, basket roller lifts it and then falls into the dyeing tank. The circulation runs to achieve the purpose of dyeing the fabric. During dyeing, the fabric is immersed in the dyeing tank in a relaxed state for most of the time, and the tension is small.

Winch dyeing machine feature

- Whole machine material is high strength corrosion-resistance stainless steel;

- High-performance drive system, and equipped with high step-less adjustable motor to adapt to different material and processing capacity;

- Heating method steam or electrical;

- Equipped with movable front door, easy to operate;

- Equipped with lighting device on the top of machine to observe inner working situation of machine clearly;

- Soft processing status to ensure that the material will not be harmed and will not produce feather;

- Reduce process time, improve production efficiency, dark fabric dyeing time only 280 minutes;

- Less water consumption, less discharge, less sewage treatment, less dyes and chemical additives, and more environmental protection;

- Power saving, the main pump motor adopts frequency converter soft start, and the discharge can be carried out without shutdown.

Technical parameters

| Dye tank volume: | 0.385m3 |

| Capacity: | 9kg |

| Liquor ratio: | l:10~1:18 |

| Lifting speed: | 30m/min(customizable) |

| Dyeing temperature: | ≤98℃ |

| Roller speed: | 35r/min |

Winch dyeing machine structure

Dye tank

The dyeing tank is made of stainless steel. The inner wall of the dyeing tank and its weld are polished and easy to clean. Strong perforated separators separate the fabric from the heating tube. The front glass windows is solid durable tempered glass, and easy to observe the inside of the fabric movement, the groove is equipped with lighting device.The device is equipped with liquid level meter, which is helpful to control liquid quantity, and thermometer for temperature control. The tank also overflows water outlet and water valve and other devices.

Roller

The basket roller, cloth guide roller and its shaft are all made of stainless steel. The u-shaped section of its support tube can prevent the fabric from slipping. It is conducive to uniform dyeing.

Heating system

Electric heating tube direct heating or steam heating.

Winch dyeing machine process

Water inlet

1. Close the drainage valve.

2. Open the water inlet valve and close the water inlet valve when the water reaches the required water level.

Feed in

1.Check whether the water level in the tank is the required water level.

2. Open the cloth guide roller.

3. Feed the end of the cloth to be dyed from the guide roller into the dye tank.

4. Hook the cloth head out of the cloth slot with a cloth hook and put it aside until it is about 2 meters into the cloth.

5. Stop the guide roll. Connect the cloth end to end, and then open the cloth guide roller to circulate the cloth.

Add dye chemicals and additives

Dyeing chemicals and additives according to process requirements.

Washing

1. Open the water inlet and drainage valves at the same time for circulating water washing, and pay attention to the inflow and displacement must be consistent.

2. After washing, close the water inlet valve and open the drainage valve. After finding the cloth head, close the cloth guide roller.

3. Untie the cloth head, pull it out and put it on the cloth-out roller. Open the out cloth motor and cloth can be released.

Winch dyeing machine development

Since the 1960s, the new equipment types of winch dyeing machine are jet dyeing machine, normal temperature overflow dyeing machine, airflow dyeing machine and so on. Jet dyeing machine is an intermittent dyeing equipment with high effect, which is suitable for dyeing synthetic fiber fabrics of many varieties and small batches. It is mainly composed of dyeing tank, ejector, distributing tube, heat exchanger and circulating pump.

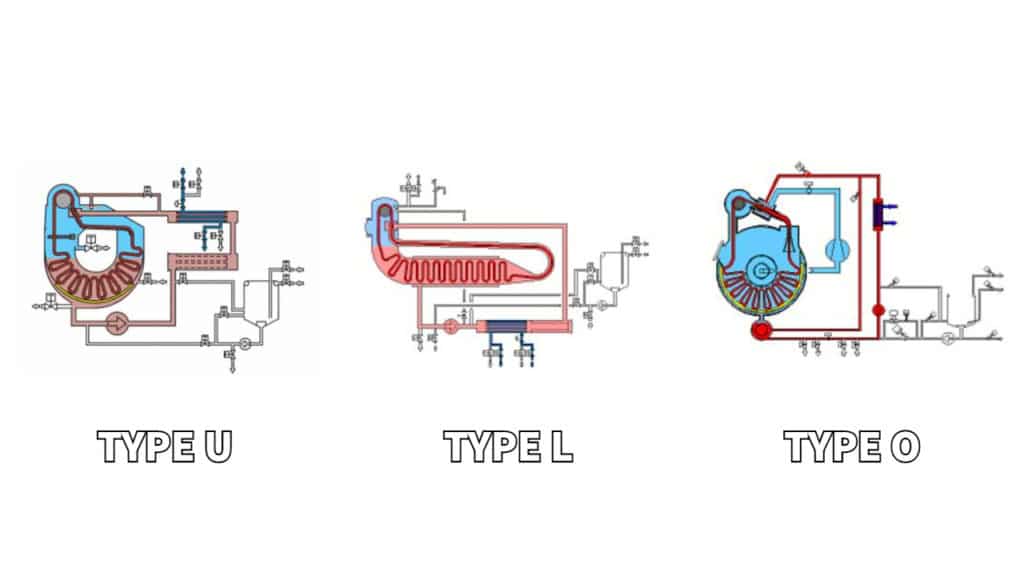

When dyeing, the fabric is connected head to tail, and the fabric is lifted from the dyeing bath by the cloth guide roller, which is driven by the liquid flow from the ejector to advance in the cloth guide tube, and then falls into the dyeing tank and is dipped in the dyeing bath in a relaxed bending shape and moves forward slowly, and is lifted again by the cloth guide roller to run circularly. The dye is driven by a high-power pump, through a heat exchanger, and then speeded up by an ejector.The following is the schematic diagram of U type, L type and O type winch dyeing machine:

FAQs

Q1: What is the difference between a capstan dyeing machine and a jet dyeing machine?

A: The capstan machine uses a cloth guide roller circulation system with lower tension, which is suitable for silk/wool fabric dyeing processes; the jet machine propels the fabric through liquid flow, which is more suitable for high-speed dyeing of chemical fibers.

Q2: How to extend the service life of the capstan dyeing machine?

- Clean the residual dye in the dye tank weekly

- Check the lubrication of the cloth guide roller bearing every month

- Calibrate the temperature sensor every quarter

Q3: How to choose between laboratory-grade and industrial-grade models?

A: WE-1 (load ≤ 9kg) is recommended for laboratories, and high-temperature and high-pressure models (load ≥ 50kg) are selected for industrial scenarios.

Comments are closed.

I am very much pleased with the contents you have mentioned. I wanted to thank you for this great article.

Admiring the time and effort you put into your blog and detailed information you offer!

Wonderful illustrated information. I thank you about that. No doubt it will be very useful for my future projects. Would like to see some other posts on the same subject!

I value the blog article.Much thanks again. Want more.

Excellent write-up. I certainly appreciate this website. Continue the good work!

I value the information and counsel you have provided. I’ll attempt to figure it out for further information.

I can’t believe how much I’ve learned from reading your blog. You have a real gift for teaching and explaining.