Air Flow Dyeing Machine Overview

Last Updated: April 29. 2025

Air flow dyeing is a modern dyeing process characterized by its low liquor ratio airflow dyeing machine design, reduced energy consumption, and minimal environmental impact, making it a 21st-century eco-friendly dyeing solution. This article explores its mechanism, advantages over traditional methods, and applications.

Contents

Introduction

Overflow dyeing machines have long dominated textile factories due to their versatility, compact size, and ability to handle small batches. However, their high bath ratios, energy inefficiency, and pollution issues became unsustainable as environmental concerns grew. Enter the airflow dyeing machine—a revolutionary high-efficiency airflow dyeing technology that addresses these challenges while maintaining fabric quality.

Since the end of the 1980s, with the increasingly prominent environmental problems and the development trend of fabric quality becoming more and more high-end, traditional overflow dyeing machines have gradually exposed many problems, such as large bath ratio, high energy consumption, large sewage discharge, and fabric pollution. Defects such as low speed. In particular, the problem of pollution constitutes damage to the ecological environment. The airflow dyeing machine came into being.

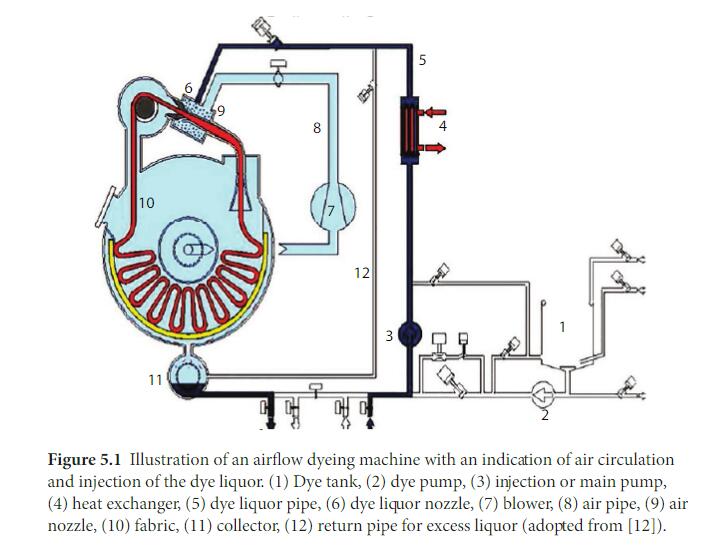

Mechanism principle of airflow dyeing machine

Airflow dyeing replaces water-driven fabric transport with high-speed airflow systems. A high-pressure fan generates airflow through specialized nozzles, propelling fabric while atomizing dye into a fine mist. This ensures rapid, uniform dye-fabric contact, achieving level dyeing with a low liquor ratio (as low as 1:3).

In contrast to the overflow dyeing machine, water is simply utilised as a transport of dying ingredients, and the cloth is driven by high-speed airflow. As a result, its liquor ratio may be quite low. Second, the circumstances for dye liquid absorption varies. The cloth absorbs the dye bath from the dye liquor spread on the fabric’s surface rather than the surrounding dye liquor.

Airflow dyeing machine structure

Fans, circulating pumps, nozzles, dyeing tanks, fabric lifting rollers, cloth discharge rollers, and airflow and liquid circulation pipes are the key components of an airflow dyeing system.

The nozzle is the most important component, and it is responsible for the formation of high-speed airflow as well as the atomization effect of dyes and chemicals. Round and square are the two kinds of nozzle. The round nozzle is ideal for processing microfiber, synthetic fiber simulated knitted textiles, and woven fabrics, while the square nozzle is ideal for processing heavier fabrics and ropes that can be rotated easily.

Features of airflow dyeing machine

Short dyeing cycle and high efficiency

The heating rate can reach 8-10 °C min due to the small liquor ratio and high heat exchange efficiency, greatly reducing the heating time from room temperature to 90 °C. Second, the dye liquor circulation is quick, the cloth speed is high, the fabric can be exchanged with the dye liquor many times in a short period of time, and the dyeing can be quickly absorbed under full level dyeing conditions.

Fully washed

Despite the fact that the liquor ratio of air flow dyeing is low, water is sprayed into the cloth by a jet system as a result of the continuous washing technique. And, depending on the process needs, the jet pump in the jet system may immediately create a 60-80 °C hot water bath, providing an excellent cleaning effect.

The dyeing quality is reliable and reproducible

- After being atomized by airflow, the dye liquid is sprayed directly on the surface of the cloth, with great penetration and a large and homogeneous contact surface.

- The cloth lifting roller just serves to reverse the fabric, and the airflow is the fabric’s power source. As a result, even at high speeds, the fabric will not produce a lot of tension.

- The density of the air flow is lower when dyeing light and thin materials, and it is gentler even at high speeds. As a result, the air dyeing equipment does relatively little harm to the cloth.

- It is easy to develop a lot of foam during the liquid flow dyeing process, especially when half-filled, therefore defoamer must be applied. Because the cloth is enveloped by an air-water mixed environment in airflow dyeing, no foam is produced.

More about the yarn dyeing reproducibility Issues.

Eliminate the phenomenon of blocking cloth and knotting

Many overflow dyeing machines now have a swing component to improve cloth stacking in the tank’s transverse direction. Not only does the airflow dyeing machine include a swing device, but it also has no dye bath in the tank. The fabric moves forward in the tank by its own weight along a highly smooth surface, and the relative displacement between the cloths is negligible. As a result, the accumulation state of the fabric dropping from the cloth guide tube is essentially retained, and fabric knotting in the tank is prevented.

Unlike the overflow dyeing machine, the air dyeing machine’s cloth take-up roller is not the primary power source for fabric conveying. As a result, there will be no obstruction owing to a mismatch between the linear speed of the cloth lifting roller and the nozzle’s airflow speed.

Adapt to a wide range of fabrics

Air-flow dyeing may be used on any cloth that can be dyed using standard overflow dyeing. Second, it has good level dyeing for various high-grade materials, such as Tencel fiber fabrics, fake peach skin and faux suede fabrics, and the hand feel is excellent.

With a multi-purpose function

The present dyeing machine development trend aims to realize the multi-purpose function of a single machine. Any user would want to get the most powerful equipment for the least amount of money. In this regard, by adding various auxiliary devices with their own intrinsic properties, the airflow dyeing machine may be utilized for different applications. For example, adding an air heater, a steam-water separator, and some more pipes can result in an excellent loose drier; adding a softener and adjusting the air volume suitably will soften the cloth.

FAQs

Q1: How does airflow dyeing reduce environmental impact?

Its low liquor ratio airflow dyeing machine design cuts water use by 50–70% and energy by 30–50%, aligning with eco-friendly air flow dyeing solutions.

Q2: What fabrics work best with airflow dyeing?

Ideal for synthetics, knits, and delicate materials like Tencel. The airflow dyeing machine for synthetic fabrics ensures minimal tension and even results.

Q3: Can airflow machines replace overflow dyeing?

Yes, especially for high-volume, eco-conscious production. Their high-efficiency airflow dyeing technology outperforms traditional methods in speed and sustainability.

Q4: How to maintain an airflow dyeing machine?

Regularly clean nozzles, check airflow sensors, and use automated airflow dyeing equipment diagnostics to prevent clogs.

Q5: Are airflow machines cost-effective?

Despite higher upfront costs, long-term savings in water, energy, and waste treatment justify the investment.

Conclusion

With its brand-new concept and distinctive performance, the 21st century green and ecologically friendly airflow dyeing machine has better handled the difficulties that existed in the overflow dyeing machine. And, by extending its own current functions and adding certain accessories, it fulfills the multi-purpose function of one machine, which is a machine with a lot of potential for development.

Comments are closed.

It is always great to stumble across an interesting topic of yours like this.

This is such a great resource that you are providing and you give it away for free. I love seeing blog that understand the value of providing a quality resource for free.

This is a really amazing post. Generic information which all should know. Seriously I didn’t know about that of this site.

very amazing Information. Really impressed after reading this blog Information.

Excellent post. Every day, I learn something new on the blogs.

This is pure gold. You have a real talent for making complex topics easy to digest.