Jet Dyeing Machine:Classification, Characteristics and Development Direction

Contents

Introduction of rope dyeing machine

Jet dyeing machine belongs to a rope dyeing machine, want to understand the jet dyeing machine must first understand the rope dyeing machine.

Rope dyeing machine is mainly used for rope dyeing of wool fabric, silk fabric, chemical fiber wool like fabric, silk like fabric and cotton, cotton blended knitted fabric which is not suitable for bearing tension and pressing. It can also be used for some silk fabrics, cotton and its blended knitted fabrics, such as scouring bleaching, washing, washing and other processing. Because this kind of fabric is easy to stretch, bruise and loose, so do not pad or curl dyeing.And dyeing equipment should meet the fabric to bear small tension. Basic requirements and fabric and small friction, for different reasons, often called disseminated (exhaust dyeing). Up to now, this kind of equipment has various forms and varieties, including normal temperature and pressure rope dyeing machine, normal temperature and pressure overflow dyeing machine, high temperature and high pressure overflow dyeing machine, jet dyeing machine and new airflow dyeing machine.

Type of jet dyeing machine

HTHP overflow jet dyeing machine

In order to adapt to the high temperature and high pressure rope dip-dyeing process of some synthetic fabrics, the atmospheric pressure rope dip-dyeing machine is placed in the horizontal pressure resistant pot body at first, and the high temperature and high pressure dyeing is carried out under the sealed state. However, the fabric is easy to tangle in operation, and the treatment of lowering pressure and opening cover is very inconvenient, and the dyeing effect is not good enough.With the increase of the yield and variety of synthetic fiber and its blending, interwoven knitted fabric and woven fabric, the rapid development of high temperature and high pressure loose rope intermittent dyeing machine was promoted in the mid-1960s. Because this kind of dyeing machine forces the dyeing liquid to flow in the machine by circulating pump, and pushes the fabric movement, so it is called liquid flow dyeing machine.There are many types of such dyeing machines, which are still in continuous improvement and development; The development of the general situation is the use of dye overflow action, spray action and designed into overflow, spray type, spray plus overflow, and so on. From the bath ratio size trend, is to small bath ratio development. Because many dyeing machines have their own characteristics for fabric varieties and dyeing processes, they are currently being improved and developed in coexistence.

HTHP jet dyeing machine

Since GastonCounty exhibited the first high temperature and high pressure jet dyeing machine in 1967, various types of jet dyeing machines have appeared successively, and the development is more rapid in recent years. The idea of dyeing with jet and liquid flow driving the movement of fabric was to help the dyeing liquid penetrate into the rope-like fabric, accelerate the dyeing effect of dye on fiber, reduce the bath ratio, and get better dyeing effect. There are many types of high temperature and high pressure jet dyeing machines, which can be divided into tank type and pipe type.

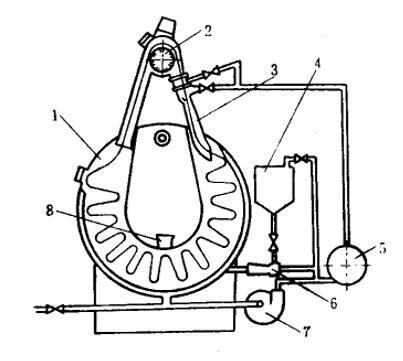

1. HTHP tank jet dyeing machine

Tank structure is conducive to pressure, compact structure, small occupation area, tank dye liquid is half full state, bath is relatively small (7~10:1). The rope-shaped fabric which is sprayed by the nozzle and pushed by the liquid flow is stacked compact in the J-shaped box in the tank, which is conducive to the implementation of small bath ratio dyeing.

At the same time, due to the large space of shaking cloth, the fabric is not easy to tangle; Using jet dyeing, fabric running fast and not easy to produce lasting crease. However, foam will be produced in the dyeing process, and antifoaming agent is often needed. There are generally 1~6 dyeing tubes in the tank, which can be purchased as needed. The maximum operating temperature of the machine is 140℃.

In order to prevent the adverse effect of dyeing liquid spraying force on some kinds of fabric, spraying and overflow flow is developed. ME215-2 high temperature and high pressure spray dyeing machine shown in the picture is one of the dyeing machines. It has two dyeing tubes, the maximum cloth capacity is 120kg/ tube, the bath ratio is 5~ 7∶1, and the operating temperature is 135℃.The characteristic of this machine is that by adjusting the nozzle, it can be used for overflow, spray, overflow spray combined with three different states of dyeing; The pulley is driven by DC motor stepless speed regulation, speed regulation according to the need; The dyeing process is controlled by program. Therefore, it can be applied to the high temperature and high pressure dyeing of synthetic fiber, blended and interwoven knitted fabric of 50~300g/ m2, with strong adaptability, short dyeing cycle, and reduced consumption of water, electricity, steam and dyeing materials.

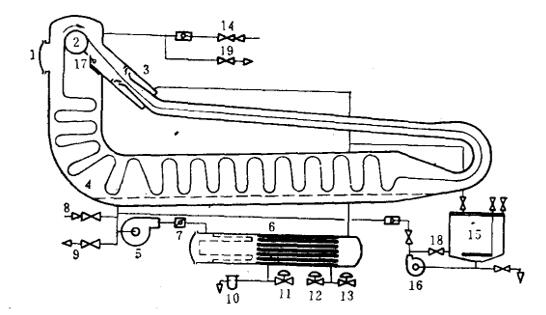

2. HTHP pipe type overflow and jet dyeing machine

The shape of the dyeing machine is pipe-like, and the body is composed of a cloth storage tube and a cloth guide tube. The cloth guide pipe can be located above or below the cloth storage pipe. The dyeing liquid in the cloth storage tube can be fully filled or semi-filled, which can be adjusted according to the requirements of the dyeing process. The tension of the rope fabric is very low in the process of dyeing because it is in a lying and relaxed state in the storage tube. Because the nozzle is generally immersed in the dye solution, not easy to produce foam, so can not add defoaming agent.This kind of dyeing machine covers a slightly larger area than the tank type, and the general bath ratio is 5-10∶1. Pipe dyeing machine is usually overflow and spray dyeing, but also overflow dyeing, light and thin soft and sensitive fabric is not easy to scratch, also not easy to produce permanent wrinkle printing, so it is especially suitable for light and thin fabric dyeing.

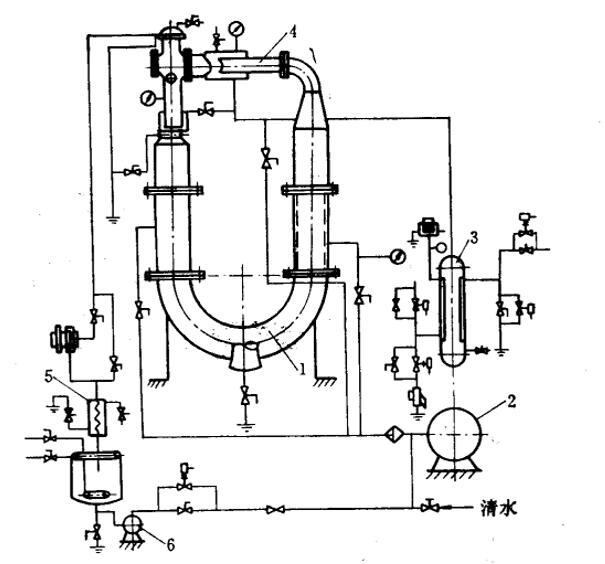

3. U-shaped HTHP jet dyeing machine

As shown in the picture, the body of the vertically mounted U-shaped stainless steel plate welded by the machine is filled with dyeing liquid, which is heated by circulating pump through heater and sprayed into the machine by nozzle. At the same time, the dye liquid returns to the circulating pump along the returning liquid device through the filter, forming the dye liquid circulation in the machine. The loose ring fabric accumulates in the body through the cloth guide tube under the spray force of the spray nozzle, and runs continuously in circulation under the thrust of the dye liquid flow.The speed of fabric delivery can be controlled by the regulating valve and displayed by the speed measuring device.

The fabric capacity of the machine is 85~100kg, the bath ratio is 9:1, the fabric running speed is about 2m/s, the highest working temperature is 130 ℃. The main circulation pump and feeding pump are centrifugal corrosion resistance pump. The machine is full of dyeing liquid, rope fabric is always immersed in the dyeing liquid in a relaxed state, not easy to produce foam, the appearance of the dyed product is plump, feel good; The organization is also simpler and occupies less space.

4. Q72-2 HTHP jet dyeing machine

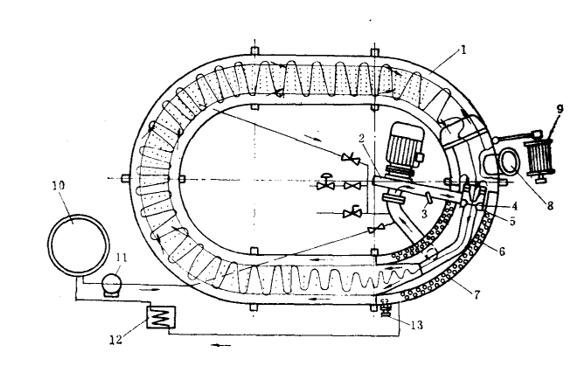

The instrument is a horizontal oval tube (commonly known as wheel type) full high temperature and high pressure jet dyeing machine, can be divided into single layer and double layer.

As can be seen from the overlooking structure diagram of the machine in picture, the loose ring-rod-shaped fabric in the oval stainless steel tube was driven by the liquid flow sprayed by the jet. The nozzle is composed of a nozzle and a spray cage, and there is an adjustable 0-10mm annular gap between the conical tubes to form a nozzle. Nozzle caliber is divided into 50, 60, 70mm three kinds. When selecting nozzle and spray cage, it is advisable to squeeze the section of the fabric equivalent to 1/3 section of the nozzle.

The bath ratio of this machine is 9:1, and the consumption of water, steam and electricity is decreased. The maximum fabric capacity is 140kg, the maximum working temperature is 140℃, the fabric running speed is 150-260m/min, the liquid volume is 1400L. Because the fabric is dyed by liquid flow in the lying tube full of dyeing liquid, the fabric tension is small and the dyeing effect is good.

Improvement and development trend of jet dyeing machine

Overcome bubbles

As previously mentioned, such machines tend to have a small bath ratio whereas the foam produced during dyeing does not differ knat at the quality of the dye and is prone to tangling of the fabric, one of the major drawbacks of semi-full jet dyeing machines, which can be addressed by the addition of an antifoaming agent.In recent years, the nozzle of many semi-filled jet dyeing machines is fully submerged, which can effectively prevent the air from entering the nozzle and producing foam. In addition, there are also equipped with a bypass pipe, the foam in the storage pipe is led out, or the combination of overflow and spray nozzle liquid sealing device, to reduce the foam has a certain positive effect.

Prevent tangles

In the process of running in the machine, the rope fabric can not be dyed normally because of irregular piling, twisting, tangling and even tearing. In recent years, in order to prevent fabric twisting and tangling, the following measures have been adopted: the tank type jet dyeing machine adopts a cloth lift, so that the fabric has a chance to shake loose before entering the nozzle.For the jet dyeing machine with faster fabric running speed, the distance between the roller and the liquid level is also slightly increased. The nozzle section tends to be rectangular and has a certain spreading effect. It is reasonable to design a rectangular section of the cloth guide tube behind the nozzle, which can eliminate the spiral twist of the fabric caused by the eddy current of the dyeing liquid, reduce the hydraulic loss caused by the eddy current of the dyeing liquid, and is conducive to uniform dyeing. When the rope fabric self-guiding cloth tube falls into the cloth storage tube, the pneumatic manipulation device is used to make the fabric pile neatly and regularly.

Reduce creases

In jet dyeing, it is easy to produce longitudinal and transverse creases, which is related to the longer extrusion time of fabrics in the dyeing process. Therefore, it is beneficial to reduce creases by taking measures to improve the running speed of the fabric for tank and pipe dyeing machines, so that the relative extrusion position can be changed at an interval of about 1~2min.Also in the cloth storage groove using a horizontal cage or shaft drum for low speed rotation, reduce the fabric by gravity extrusion. In addition, a cloth feeding device similar to a conveyor track can also be used, or the porous cloth storage groove in the pipe type cloth storage pipe can be oscillated up and down. It is worth noting that some dyed woven fabric congestion, creases are often related to the self-priming height of the circulating pump, must be selected or designed appropriately.

Avoid bruising

Fine sensitive fabrics are often easily scraped by jet dyeing. In recent years, the measure of overflow and spraying is generally adopted to reduce the nozzle pressure and make the fabric not easy to scratch. Also can USE the runner, the drum, or in the fabric at the bottom of the storage groove contact wall using PTFE board or coating, or use stainless steel conveyor belt, to avoid fabric abrasion has a certain effect.

QR630 High Temperature Jet Dyeing Machine

Application

QR630(A) Series High Temperature Jet Dyeing Machine is suitable to test the dyeing of fabrics; the design target of this machine is especially for the small quantities of fabrics.

Feature

- Inner body of machine adopt corrosion-resistant stainless steel;

- High-efficiency stainless steel centrifugal pump to provide optimal dye cycle;

- Lifting roller driven by frequency inverter controlled motor;

- Service tank equip with the feeding pump, valve, dye cycle system;

- Level monitor equip with magnetic sensor;

- High efficiency heat exchanger;

- Fill water, drain water, heating up, cooling of the main tank all automatically;

- Pneumatic valve for fill and drain function;

- PLC control(QR630A);

- Fill dyestuff,stirring,heating, fill water,drain all can be carried out automatically(QR630A);

Specification

| Model No. | Capacity | Power |

| QR630(A)-1 | 1-2kg | 4.0kw |

| QR630(A)-5 | 4~6kg | 5.9kw |

| QR630(A)-15 | 8~15kg | 7.7kw |

| QR630(A)-30 | 20~30kg | 9.3kw |

| QR630(A)-60 | 40~60kg | 11.2kw |

| QR630(A)-120 | 80~120kg | 11.2kw |

Comments are closed.

I’m so glad that I came across this awesome post,

Much thanks to you again for all the information you disseminate, Good post.

I have recently started a blog, the info you provide on this site has helped me greatly. Thanks for all of your time & work.

It is one of the finest websites I have stumbled upon. It is not only well developed, but has good content as well.

The essay is a fantastic idea, and I really like how you express the notion of jet dyeing machine.

You have a unique perspective that I find refreshing and enlightening.

I’m so impressed by how you manage to make even the driest of topics seem interesting and relevant.