A Quick Overview of Drop Weight Impact Tester

In the field of material testing, understanding a material’s impact resistance is critical for guaranteeing safety and performance in a variety of applications. The Drop Weight Impact Tester is a crucial instrument for both engineers and researchers, providing valuable insights into material toughness and durability. This gadget assesses how different materials behave to impacts by replicating real-world settings where abrupt shocks may occur, which guides design and manufacturing decisions. In this post, we will look at the fundamentals of drop weight impact testing, such as its operating principles, applications in various industries, and the importance of testing standards. Whether you are new to material testing or looking to enhance your knowledge, this overview will provide a solid foundation for understanding the importance of this vital equipment.

Contents

Introduction

What is Drop Weight Impact Tester

The drop weight impact tester is a test machine used to test the impact resistance or impact ability of a material. It is also known as falling weight impact tester and drop weight testing machine.

How does it work?

The working principle of the drop weight testing machine is to use the free fall of a heavy object (i.e. a drop weight) to hit a material sample from a certain height, and to evaluate the impact resistance of the material by measuring the deformation and damage of the sample after the impact. During the test, the drop weight has a certain initial velocity to ensure that a sufficient force is applied to the sample to produce a typical impact effect.

Application Areas

Applicable industries

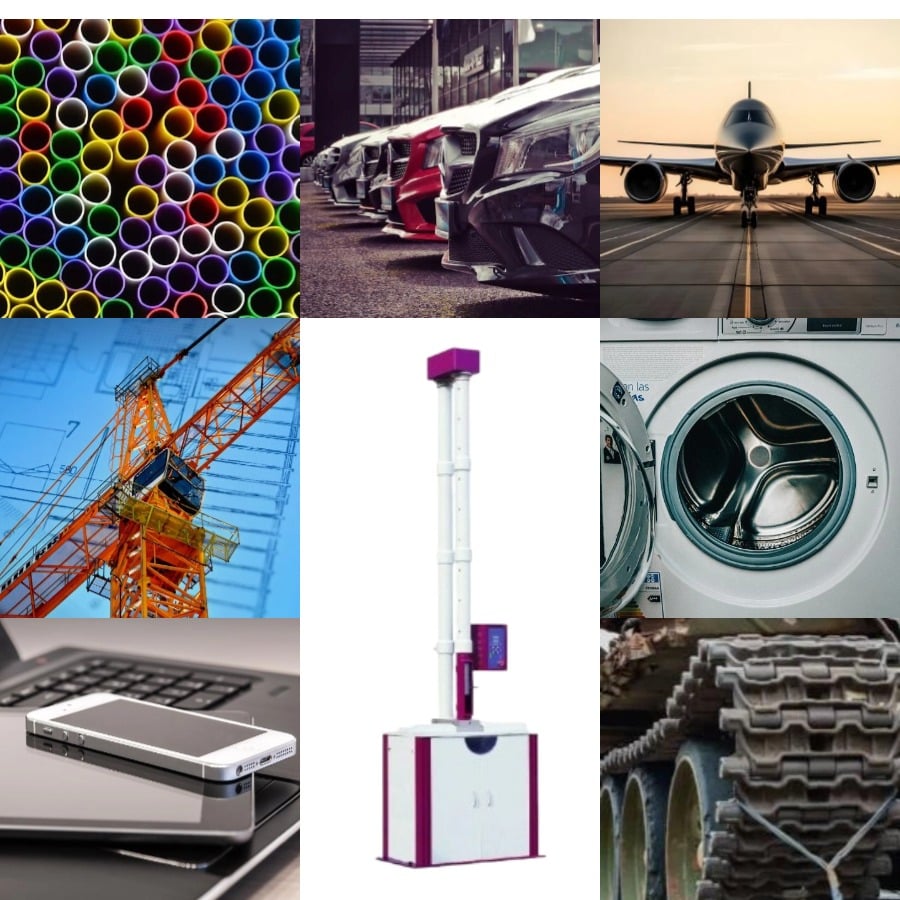

Drop weight impact testing machines are widely used in many industries, mainly including the following aspects:

- Materials Science: used to test the impact resistance of materials such as plastics and rubber.

- Automotive Industry: evaluate the safety and durability of automotive parts in the event of a collision.

- Aerospace: test the strength and toughness of aircraft and their components under extreme conditions.

- Construction Engineering: test the impact resistance of building materials (such as concrete and steel) to ensure structural safety.

- Consumer Electronics: drop tests on electronic products such as mobile phones and tablets to evaluate their durability.

- Military Industry: test the impact resistance of weapons and equipment and protective materials to ensure their reliability.

- Home Appliance Industry: test the impact resistance of home appliances during transportation and use.

These industries use drop weight testers to ensure product quality and safety, meet relevant standards and customer requirements

What materials can falling weight impact tester test

Drop impact test machine is suitable for PVC-U pipe, PVC-C pipe, PP pipe, PE pipe, communication pipeline, etc.

Test Standards

Drop weight impact testing machine complies with the following standards:

ISO 4422:Pipes and fittings made of unplasticized poly(vinyl chloride) (PVC-U) for water supply — Specifications

ISO 3127 :Thermoplastics pipes — Determination of resistance to external blows — Round-the-clock method

BS EN 1411: Plastics piping and ducting systems – Thermoplastics pipes – determination of resistance to external blows by the staircase method (Withdrawn)

BS EN 744:Plastics piping and ducting systems – Thermoplastics pipes – Test method for resistance to external blows by the round-the-clock method

Main features of drop weight impact tester

This drop weight impact testing machine has several significant advantages and features that make it an ideal choice in the field of materials testing. First of all, the device is equipped with an LED display, which not only provides intuitive data display, but also ensures a long operating life. The application of LED technology makes displays more durable and reduces downtime caused by traditional display failures, thus improving overall efficiency.

Secondly, the impact height of the testing machine can be adjusted from 50 to 2000 mm, providing flexibility to meet different testing needs. Users can easily adjust the height as needed to simulate impact situations in a variety of real-world applications. This high degree of adjustability allows the equipment to adapt to the testing requirements of a variety of materials and products.

In addition, the testing machine adopts an imported servo motor control system and a rapid lifting device, which greatly improves work efficiency. Compared with traditional mechanical devices, servo motors can achieve better precise control and respond faster during the lifting process, ensuring that each impact can reach the set parameters, thereby improving the repeatability and reliability of the experiment.

The equipment also has the function of automatically calibrating the lifting height, and the calibration accuracy can reach ±2mm. This feature ensures the consistency of each experiment, avoids the impact of human operating errors, and makes the experimental data more accurate and credible.

In terms of strikers, the device is designed as a combined striker, and users can assemble strikes of different weights as needed. This design allows the testing machine to conduct special tests on the characteristics of different materials, expanding its application scope. At the same time, the configuration of the pneumatic capture device effectively prevents the occurrence of secondary impact phenomena, further ensuring the reliability of the experimental results.

Finally, the testing machine is also equipped with a combined V-shaped block, suitable for specimens of different diameters. This design ensures that during the impact test, the sample can be stably fixed and not easy to slide, ensuring that each test can be conducted under the same conditions, thereby improving the comparison of data.

To sum up, with its advanced technology, flexible adjustment capabilities and efficient operating procedures, this drop weight impact testing machine has become an ideal tool for material testing in various industries, providing users with accurate and efficient testing solutions.

Drop Weight Impact Tester vs. Pendulum Impact Tester

The drop hammer test is a test in which a hammer body falls from a set height onto a sample (a sample product of a plate or pipe) to obtain the relationship between the drop height and mass and the sample damage rate. The drop height and mass when the damage rate is 50% are used to express the impact resistance of the calculated sample. The drop hammer test is divided into a pipe test and a plate test. The pipe test is divided into a pass method and an up-and-down method, and the plate test is divided into a constant mass method and a constant height method. It should be noted that when energy is expressed, the results of different heights or different weights should not be compared.

The pendulum impact test is a test in which a freely falling pendulum hits a sample placed on a test stand. The lower end of the sample is fixed. It can be notched or notched. The impact strength reflects the energy loss of the pendulum when the sample is damaged by impact. The impact strength can be expressed as energy per unit sample width or energy per unit sample cross section.