What is Pipe Thermal cycling tester ? How does thermal cycling tester for pipe systems work ?

Contents

What is Pipe Thermal cycling tester?

Thermal cycling tester DW5380 is mainly used to determine the leakage status of composite pipe & fittings when subjected to specified cycling times under specified internal pressure load. The instrument is mainly used for pipe pipe assembly after the pipeline system test. Application requirements for thermoplastic pipe fittings system for hot and cold water systems.

This machine meet with belows standard :

GB / T 18998 << Industrial Chlorinated Polyvinyl Chloride (PVC-C) Piping System >>

ISO 10508-1995 << Thermoplastics pipes and fittings for hot and cold water systems >>

GB / T 18993-2003 << Chlorinated Polyvinyl Chloride (PVC-C) Piping System for Hot and Cold Water >>

GB / T 18742-2002 << Polypropylene Piping System for Hot and Cold Water>>

CJ / T 138-2001 << Technical requirements for pipe fittings for cross-linked polyethylene (PE-X) pipes for construction purposes >>

Composition of Thermal Recycling Testers

1.2.1main electric cabinet, cold/hot alternation execution module, chiller and sample chamber. Flowing is the sketch of configuration and connections.

1.2.2 TCA (thermal cycling apparatus) can be designed into 3 or 6 stations (if different, pls. specify).

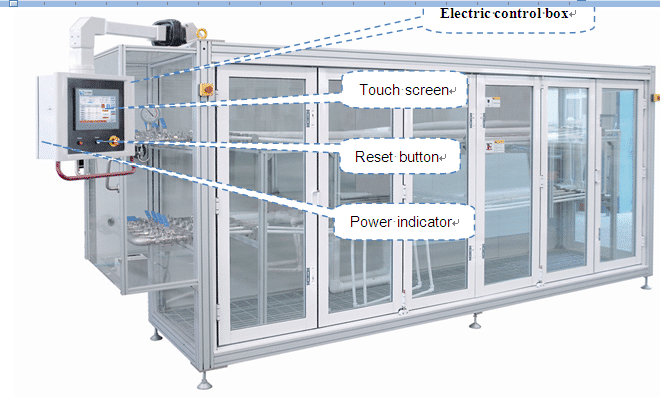

1.2.3 Front panel of main electric cabinet (see Fig. 1)

Specifications of Pipe Thermal Cycling Tester

Specification of thermal cycling tester for pipe systems s described as below:

| Test stations | 6 |

|---|---|

| Max. measurement area | 6200mm2(2×Φ63)(can be customized) |

| Cold water or hot water circulation time | 600s~1800s(random) |

| Cold/hot alternation time | Within 60s |

| Circulation times | 0~100000 (random) |

| Max. length of straight pipe | 3700mm |

| Display method | Touch screen display |

| Control method | PLC |

| Flow rate | >0.9m/s |

| Water tank volume | 600L |

| Temperature range | 20℃~room temperature (room temperature > 20℃) |

| Temperature control accuracy | set value ±2℃ |

| Temperature uniform | ±1℃ |

| Water tank volume | 600L |

| Temperature range | Room temperature~95℃ |

| Temperature control accuracy | Set value±1℃ |

| Temperature uniform | ±1℃ |

Pipe Thermal cycling tester Features

- Several reliable safeguard, e.g. liquid level measuring devices, emergency stop switch and cord switch ensure the tester to be out of action in time if the test fails or piping system bursts. Doors shall be locked during testing period;

- High quality pumps are used to provide pressure in sample stirrings. Automatic water filling design ensures full tank capacity during the whole time;

- Quick calibration. System enables pressure calibration and temperature calibration during testing, it means that system may continue running during calibration.

How does thermal cycling tester for pipe systems work ?

Installation

1.Unpack it and check whether the document and accessories according to packing list.

2.Check whether the site area fulfill the requirement.

3.Check whether the power supply conforms to its national standard.

4.Install pipeline according to installation diagram.

5.To finish electrical installation according to the drawings (cable cod should be correspondent with the terminal No.

6.Install samples according to test standard.

7.Connect all the electrical connection wire and check it carefully.

8.Connect air supply and make sure a steady output of 0.5Mpa (at least). Check the Pneumatic pipeline , to test the manual control valve and whether pneumatic valve works (ON and OFF) freely

9.Install the chiller at perfect position and connect pipe line as well as electrical control wire.

10.Connect pipeline between water supply port and water supply, open the valve of water supply to check its performance. If there is leakage in the pipeline, pls. deal with it immediately.

Test preparation

- Joint sample of pipeline and if there is defect after visual survey, pls. change another pipe.

- Check upper liquid level of cold and hot water tank, if upper liquid limit has been achieved, pls. add up water on time.

- Then check whether air supply has been connected well and whether there is air leakage in pneumatic pipeline and deal with it on time.

- Check electrical circuit connection and make sure the input power confirms to its requirement .

Sample installation preparation

Install testing pipeline according to test requirement.

According to the standard, the free length in Branch A should be 3000mm±5mm ; There should be at least 2 sections of straight pipe in Branch B, and free length for each section should be at least 300mm±5mm; There should be at least 3 sections of straight pipe in Branch C,

If you need more information about thermal cycling tester for pipe systems theory or thermal recycling testers price , please send email to [email protected].

You have captured the essence of the topic beautifully in this article.