5 Facts Everyone Should Know about Jigger Dyeing Machine

Jigger dyeing machine is one of the equipment of batch dyeing (also named exhaust dyeing). Its corresponding dyeing method is exhaust method. This machine comes in handy when we need to dye woven fabrics.

Contents

Jigger dyeing process

Jigger dyeing belongs to batch dyeing. During the jigger dyeing process, the dye liquor stays still. And the fabric moves back and forth through the dye liquor by the jigger dyeing machine. This is very similar to winch dyeing process. Among this process, the temperature and pressure may be very high. So that the migration of dye molecules from the dye solution can move into the piece of fabric easier.

What is jigger dyeing machine?

Jigger dyeing machine is one of the open-width batch dyeing machine. Different from the rope dyeing machine. The fabric will be more uniform and not easy to form creases when dyeing in jigger dyeing machine. In addition to mainly used for direct, reactive, vulcanized, reductive and other open-width dyeing. This type of dyeing machine can also be used for small batch desizing, scouring, bleaching, washing, soap cooking and dyeing post-processing. It’s not good as continuous dyeing machine in efficiency, quality, cost and operation strength. But because it is flexible, simple structure, simple operation, less investment, it is still widely used. Especially suitable for many varieties, small batch production.

The structure of the machine

Jigger dyeing machine is mainly composed of dyeing bath, front roller and rear roller. The fabric is first rolled in an open width on the front roller. And then it goes on the rear roller after passing the dye liquor. When the fabric is about to be fully wound on the rear roller, it is rewound to the front roller. Each winding is called one passage, and so on until the dyeing is finished. The bath ratio is generally 1:3 ~ 1:5. Some jigger dyeing machines are equipped with automatic control facilities such as fabric tension, turn and running speed, which can reduce the fabric tension and the labor intensity of workers.

Front side

- Emergency stop:Press the emergency stop button to stop the machine when there is an emergency and uncontrollable situation. (Note: When the machine turns on the switch, there is no reaction when you click the start. You can check whether the emergency stop switch is not opened.)

- Door cover: When the machine is running, the door cover needs to be covered. Avoid being scald by steam caused by excessive temperature of dye liquor.

- Draw-out roller: After dyeing, the fabric needs to be wound on the draw-out roller. Both sides of the draw-out roller are fixed with screws. After removing the screw with a wrench, remove the draw-out roller to take out the fabric.

- Dyeing bath: Here is the place to store the dye liquor, using imported SUS304 stainless steel, no rust, durable. The interior is a stepped structure that consumes a small amount of dye solution.

- Display screen: Color touch screen man-machine interface, operate easily, programmable function, presetting dyeing technics for customer;

- Button: When the preparation is complete, click the green button to start dyeing and the red button to stop dyeing.

- Temperature controller: automatic temperature control system monitors dyes solution’s temperature accurately, and display the temperature on panel digitally.

- Main switch: Power switch.

- Electric box: It contains the motor and the controller. The motor consists of two 120W precision control motors equipped with high quality reducer. The controller adopts industrial programmable logic controller (PLC), high reliability, strong anti-interference ability.

Back side

- Condensate outlet: The steam produced by the dye liquor due to high temperature is discharged from the condensate outlet.

- Liquid level meter: Used for measuring the liquid level of dye liquor in dyeing bath.

- Outfall: After dyeing, drain the waste liquid from the outfall.

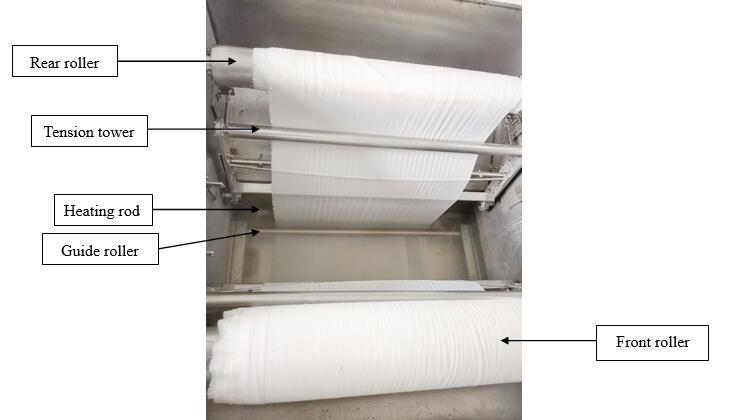

Insides

- Rear roller: One of the roll roller. Alternate with front roller to make the fabric fully dyed in the dye liquor.

- Tension tower: Auxiliary electronic controller to control the fabric tension, so that the fabric dyeing more uniform.

- Heating rod: The heating device adopts external heating technology to avoid uneven heating.

- Guide roller: Cooperate with the front roller and rear roller to make the fabric fully immersed in the dye liquor.

- Front roller: One of the roll roller. Alternate with rear roller to make the fabric fully dyed in the dye liquor.

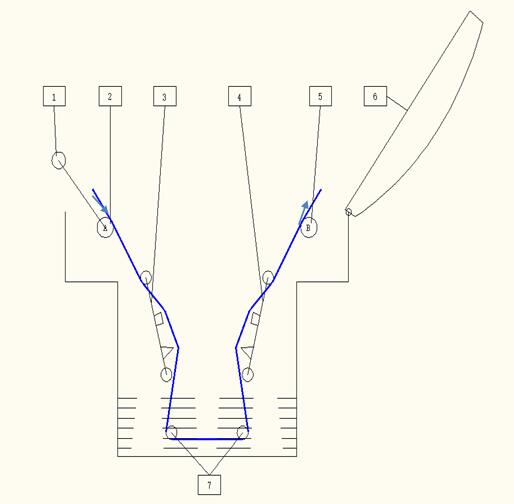

Jigger Dyeing Machine Process

At a certain temperature, the open-width fabric drawn from the front roller passes through the guide roller in the dyeing bath. Then the fabric is immersed in the dye liquor, flattened, wound to the back roll, through the spreading frame. That is the first roll dyeing. When it is about to finish, the two rollers rotate in the opposite direction. And the fabric goes into the dyeing bath for a second dyeing. Do this alternately until the number of dyeing passages specified in the process is reached. In the process of jigger dyeing, due to the mutual extrusion between the cloth layers, the dye gradually infiltrates the fiber inside, in order to reduce the color difference between the dyed fabric head and tail. Generally, the number of dyeing is an even number. Dyeing number of fabric is determined by the color of dyed fabric.

After dyeing, remove the dye liquor and rinse the fabric with water. Of the two cloth rollers, the unwinding one is a passive roller, and the winding one is an active roller. There are two roll rollers on the jigger dyeing machine. In the process of jigger dyeing, the diameter of the active roll roller increases gradually. The diameter of the passive roll roller is reduced accordingly. In order to avoid the difference of internal and external tightness or wrinkle and affect the dyeing quality. The transmission of the cloth roll should ensure that the linear velocity and tension of the fabric are maintained constant in the dyeing process. And the angular velocity of the two cloth rolls should be inversely proportional to the diameter of the winding.

Advantages and disadvantages

Advantages of jigger dyeing machine

- Open-width dyeing makes the fabric less prone to crease.

- Dyeing uniform.

- The machine operates with low material to liquor ratio (1:3 to 1:5) which saves cost.

- The small lots can be easily processed economically in a jigger dyeing machine.

- The jigger dyeing machine is the most suitable for all kinds of shades.

- The jigger dyeing machine is suitable for all kinds of processes in open width, from pretreatment to finishing.

Disadvantages of jigger dyeing machine

- It is only suitable for dyeing materials with bad effect when the machine runs under low bath ratio. And it is not suitable for places that require intense scouring before dyeing.

- High tension is applied in the warp direction. So longitudinal elongation may be as high as 5%, which causes the fabric to shrink longitudes when washed, reducing warp crimp and reducing fabric width. Tension-sensitive fabrics such as knitwear, crepe, flat crepe, mesh and elastic warp cannot be dyed on this machine

- During textile preparation, the fabric becomes slippery and unstable due to the swelling and dissolution of the slurry.

- It’s difficult to wash away the dye liquor because of the low liquor ratio.

- Because the pressure flattens the structure of the crimped fabric. Moiré effect or water marks may occur on some acetate and nylon fabrics.

JR350 jigger dyeing machine

Automatic jigger dyeing machine refers to the dyeing machine which can automatically control the turn and stop of operation. It not only can overcome the above shortcomings of large tension, but also can adjust direction, track number and stop automation. JR350 series jigger dyeing machine belongs to automatic dyeing machine. Its two roll rollers are active sticks. So that the fabric is subjected to less tension. It is very suitable for dyeing and finishing enterprises to test the dye formula before quantity production.

Comments are closed.

Hope this page is useful to anyone looking for a jigger dyeing machine.

I thoroughly read this article on the jigger dyeing machine and it is a marvelous article.

Good post. I’ve been checking this blog frequently, and I’m impressed! Very helpful information, especially the last portion. I value such information a lot. I spent a lot of time hunting for this specific information.

He has managed to create a captivating blog that kept me engaged from start to finish.