Light Fastness Standard and Test Method

Light fastness refers to the ability of colorants and polymer systems to maintain their color when exposed to sunlight. The main reason for the color change of colored products exposed to sunlight is the damage of ultraviolet rays and visible rays in sunlight to colored products.

Contents

The standard of light fastness

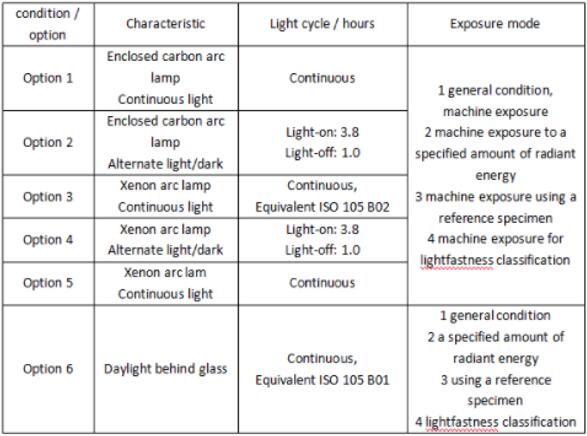

In general, the most common standards for lightfastness testing are AATCC 16, ISO 105 B02, ISO 105 B04, ISO 105 B06. ISO 105 B02 has five test methods and AATCC 16 has six test options. Among them, option 6 in AATCC 16 is equivalent to ISO 105 B01, and option 3 is equivalent to ISO 105 B02.

ISO 105

| Condition/method | characteristic | Exposure time | Color fastness evaluation |

| Method1 | Check the test sample to control the exposure cycle | The color difference of the sample reaches grade 4 and grade 3 of the gray card. | Compare it with the blue wool reference when the gray card reaches grade 3. |

| Method2 | Check blue wool reference to control exposure cycle | The color difference of No.2, No.6, No.7 blue wool references reaches gray card grade 3, grade 4, and grade 4. | Make first evaluate when the No.2 blue wool reference reaches gray card grade 3, finally make the final evaluate. |

| Method3 | exposure allowed with only two blue wool references | The color difference of blue wool with the lowest allowable fastness reaches gray card grade 4 and grade 3. | Evaluation when the gray card reaches grade 3. |

| Method4 | exposure allowed with only reference sample | The color difference of the reference sample reaches gray card grade 4 and grade 3. | Compared with the reference sample, assess “conformity” or “non-conformity”. |

| Method5 | exposure alone or exposed with the blue wool reference | Until the required amount of irradiance has been reached. | Contrast with gray card or blue wool references. |

- Method 1: Exposure time is controlled by checking blue wool reference standards, each sample should be equipped with a set of blue wool reference standards, usually used in case of disputes.

- Method 2: Control the exposure time by checking the blue wool reference value, a batch of different samples only need one set of blue wool reference value, you can save the blue wool reference value.

- Method 3: This method is used to check that the sample is consistent with known performance specifications. According to the requirements, the sample only needs to be equipped with two blue wool benchmarks, and the exposure period can also be controlled by checking the blue wool benchmarks.

- Method 4: This method is used to check that one or more samples correspond to an agreed reference sample. The essential feature is to control the exposure time by checking an agreed reference sample. Allows samples to be exposed using reference samples only, and blue wool references are not used.

- Method 5: This method is suitable for checking compliance with agreed radiation levels. The sample can be exposed alone, or the blue wool reference. Samples shall be exposed until the specified radiant energy is achieved.

AATCC 16

Color fastness to light test method

The color fastness to light test refers to a test method for testing the degree of coloration of an object against exposure to light under specific conditions. It is an important data to measure the light fastness of various substances under different exposure environments. In daily engineering technology applications, light fastness is one of the main indicators for judging materials. The most common use of light fastness testing is to measure the light fastness of inks, dyes, plastics, coatings and other materials under exposure conditions.

Types of the test method

Generally speaking, the light fastness test is divided into two types according to different modes: time exposure mode and uniform exposure mode.

Time exposure mode means that in a specific environment, the sample is exposed to light for a certain period of time before testing. At this time, the color difference caused by the measurement of light is the most important parameter;

The uniform exposure mode means that the sample is placed on a device with stable spatial conditions, accepting a certain light intensity and a specific exposure environment. After a period of time, the change in color difference reflects the color fastness to light of the sample.

In the test, in addition to the clear description of the exposure environment of the sample, other technical requirements are also important factors affecting the test accuracy. The exposure environment should choose a uniform all-white light source, the illuminance range should be within 1000~5000 lux, and the temperature should be kept at 20~25°C; in addition, in order to ensure the test accuracy, the samples also need to be reasonably protected during the test. Make sure they are not affected and damaged by external factors such as moisture, pollutants, etc.

Influencing factors

The test of color fastness to light is a complex, precise and time-consuming test, the precision and accuracy of which are largely affected by the technical requirements in the test process. In the process of light fastness testing, controlling the testing environment and exposure conditions, ensuring the accuracy and precision of testing instruments, and adopting reasonable testing methods and correct testing techniques are the basic requirements for obtaining accurate data.

Function

Light fastness test is an important technology to measure the light fastness of materials, and its evaluation results can provide a basis for the application of materials, and ensure the color stability and durability of materials in complex environments. In the evaluation of materials in many industries, the test of color fastness to light has become a consensus, which also makes the test of color fastness to light more common in practical applications.

In addition, the test of color fastness to light is also very important in the evaluation of sunscreen performance of nonwoven fabrics, especially in fabrics that meet the technical requirements of sunscreen, in addition to requiring reasonable color depth and color, good lightfastness is also required to ensure Color stability, where the color fastness to light test plays a particularly important role.

To sum up, the test is an important technology to measure the light fastness and color fastness of materials. It not only plays an important role in the light fastness evaluation of various materials, but also plays an important role in the evaluation of nonwoven sunscreen performance play a vital role. Considering the importance of light fastness test, we should prepare for the test in actual operation to ensure the quality of the test in order to obtain more accurate and reliable data.

How to improve color fastness to light?

The three ways to improve the color fastness to light have been mentioned in previous articles, and interested readers can click on the link below. https://fyitester.com/light-fastness/#How_can_you_increase_light_fastness

Leave a Reply

You must be logged in to post a comment.

I’ve been following your blog for months now, and I can confidently say that it just keeps getting better and better.

These blog posts are like a breath of fresh air – always informative, always entertaining.

Very interesting details you have observed, thanks for posting.