Understanding the Jigger Dyeing Machine: Efficiency in Textile Dyeing

There are many ways to color fibers before weaving. Traditionally, you’d dye the entire yarn or apply the color to the fiber. But, how do you dye fabric that is weaved? The short answer – jigger dyeing machine.

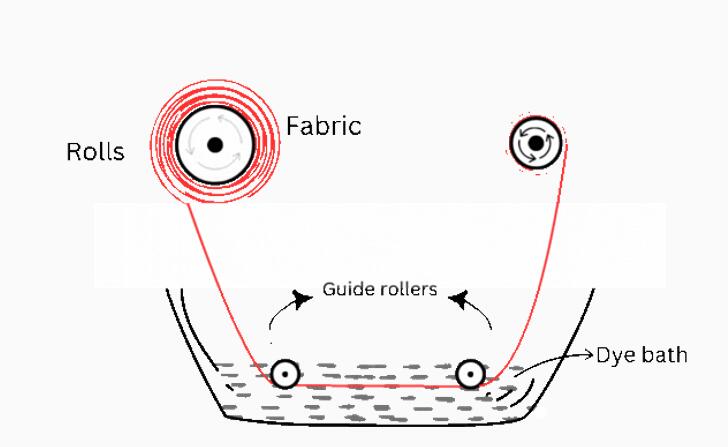

Jigger dyeing machine or a jig uses a pool of dye liquor through which a woven fabric passes onto a roller where dye gets absorbed into the fabric.

Contents

What Is Jigger Dyeing Machine?

The jigger machine works on the basic principle of passing the woven fabric through dye liquor back and forth until the dye penetrates the fabric weave.

There are multiple rollers in a jigger dyeing machine that pass the fabric through the dye liquor and wound it after an even number of passes.

Components of a Jigger Dyeing Machine

- Dyeing rollers

- Dye liquor bath

- Guiding rollers

- Tension pullers to avoid wrinkles

- Heating mechanism

- Chemical injection

The woven fabric is wound onto one of the dyeing rollers and fed through two small guiding rollers and the jigger machine wounds the fabric from one roller to another. You can use many types of dyes and a jigger machine can dye many types of fabrics.

- Plain weave fabrics like poplin, voile, muslin, etc

- Twill weave fabrics like denim and chino

- Satin weave fabrics

- Home textiles including canvas, duck cloth, and corduroy

Jigger dyeing applies tension along the length of the fabric. Jig dyeing is suitable for cotton and cellulosic fibers but for jerseys and delicate fabrics, it can unsettle sensitive weave patterns during the rolling process.

Dyeing Process

The dye bath in a jigger machine is composed of many coloring agents, solvents (usually water), and chemical agents. The choice of dye depends on the fabric.

| Dye Type | Suitable Fabric |

| Direct Dyes | Cotton and rayon |

| Reactive Dyes | Cotton and any other cellulosic fiber |

| Vat Dyes | When you need high color fastness in cotton |

| Acid Dyes | Wool and silk or nylon |

In the dyeing process, the fabric unrolls and passes through the dye bath placed lower in the machine through small guiding rollers and is wound on another dye roller.

Once all the fabric is rolled onto the second roller, the wounding direction reverses and the fabric passes through the dye bath again.

Most of the dye absorbs into the fabric when the fabric rests on the rollers. This makes the fabric speed a small contributor to color fastness

Jigger machines use steam or electrical heating to improve dye absorption. Small steam pipes extend over the dye liquor container to heat the dye bath. Some dyeing machines also use indirect heating to

To ensure uniform dyeing the dyeing process is done in a closed-lid environment. Any temperature variation can result in non-uniform dyeing of fabric.

Jigger machine is one of the oldest dyeing machines that colors the fabric on its open width and leaves no creases. The rope form of dyeing can result in unwanted creasing and marks. The tension rollers help keep the fabric in its open width.

Fabric Preparation

It is important to prepare the fabric before the dyeing cycles. This ensures there are no impurities, dirt or fuzz that can leave marks during the rolling process.

Most fabrics undergo oxidative bleaching and washing to neutralize the fabric. The starting end of the fabric is stitched on the roller for even rolling. The pre-treatment of fabric also involves processes like scouring and bleaching.

Dyeing Parameters

The dyeing process makes use of several parameters like material to liquor ratio (M:L), fabric speed, tension, dyeing depth, and dye uptake. The most important of these factors is temperature which is set according to the fabric and dye.

For reactive dyes a temperature of 60°-90°C is sufficient and for disperse dyes higher temperature (120°C-130°C) and controlled environments are used.

Although warmer temperatures help open the fibers to absorb dye, very high temperatures can degrade the dye. For most textile manufacturers a normal temperature jigger machine performs most tasks and handles all types of fabrics.

Jigger dyeing uses a M:L ratio of 1:5 or less. This is low compared to other dyeing methods like jet dyeing or print.

Washing

After the dyeing process, the fabric requires washing and post-treatment. Washing removes any loose dye and chemicals to enhance color fastness. The washing cycle involves multiple washes in hot water and rinse wash in cold water.

Advantages of Jigger Dyeing Machine

- JIgger dyeing can work with a low liquor ratio

- The Jigger machine provides easy operation for fabric dyeing

- Uniform and even dyeing

- Open-width dyeing without creasing the cloth

- Control over color fastness and dye intensity

Disadvantages of Jigger Dyeing Machine

- The Jigger machine uses tension rollers which makes it unsuitable for knitted fabrics or wool

- High tension along the fiber length can loosen the woven fabric

- The jigger dyeing process is not suitable for textiles in rope form

- Longer dyeing times because fabric passes in cycles back and forth

- Possibility of mechanical damage

Reliable Jigger Dyeing Machine | FYI Tester

Jigger dyeing machines come in many sizes and temperature control for high-quality textile production. The main difference in the machines is the vessel.

Our high-temperature jigger dyeing machine uses high-quality stainless steel and allows complete control over tension and fabric speed.

Conclusion

Jigger dyeing machines serve an important purpose in textile manufacturing. They provide an efficient and cost-effective solution when compared with yarn dyeing and fiber dyeing after the fabric has been weaved.

Jigger machine saves cost on dyes and solvents with optimal liquor ratios and provides crease free fabric dyeing ensuring uniform coating and colors.

One critical advantage of jigger machines is the possibility to work with synthetic fibers, linens, cotton, and nylon fabrics in the same machine but with different dyes. This makes it a versatile machine suitable for different textiles.

You can follow this guide to select the right jigger machine.

FAQ

● What is a jigger dyeing machine?

A jigger dyeing machine, jig dyeing or a jig is a machine that wounds fabric on its open to avoid creasing and passes it through a dye vat to coat the fabric with the dye. The dyeing fabric is wound on another roll in the machine.

● What is a Hank dyeing machine?

Hank dyeing machine is used to dye yarns with dye and a flow of steam that comes from pipes to soak the yarn with dye.

● How to use a jigger machine?

A jigger machine like JRN series requires little training and most of the process can be controlled via a small controller. You just need to set the tension, fabric speed and attach the roll to the dyeing roller to start the cycle.

● What is the liquor ratio for jet dyeing machine?

For a jet dyeing machine, the liquor ratio is around 1:8.

● What is a jig dyeing machine?

Jig dyeing is a process of coloring fabric by passing it between two rollers and through a vessel that has a vat of dye and solvent. The fabric cloth passes through the vat back and forth eventually picking color.

● What is the capacity of jigger machine?

Jigger machines come in different capacities and temperature handling ranges. Standard jigger machines can handle approximately 200 Kg of fabric and go upwards of 700 Kg.