Introduction of Universal Testing Machine

Contents

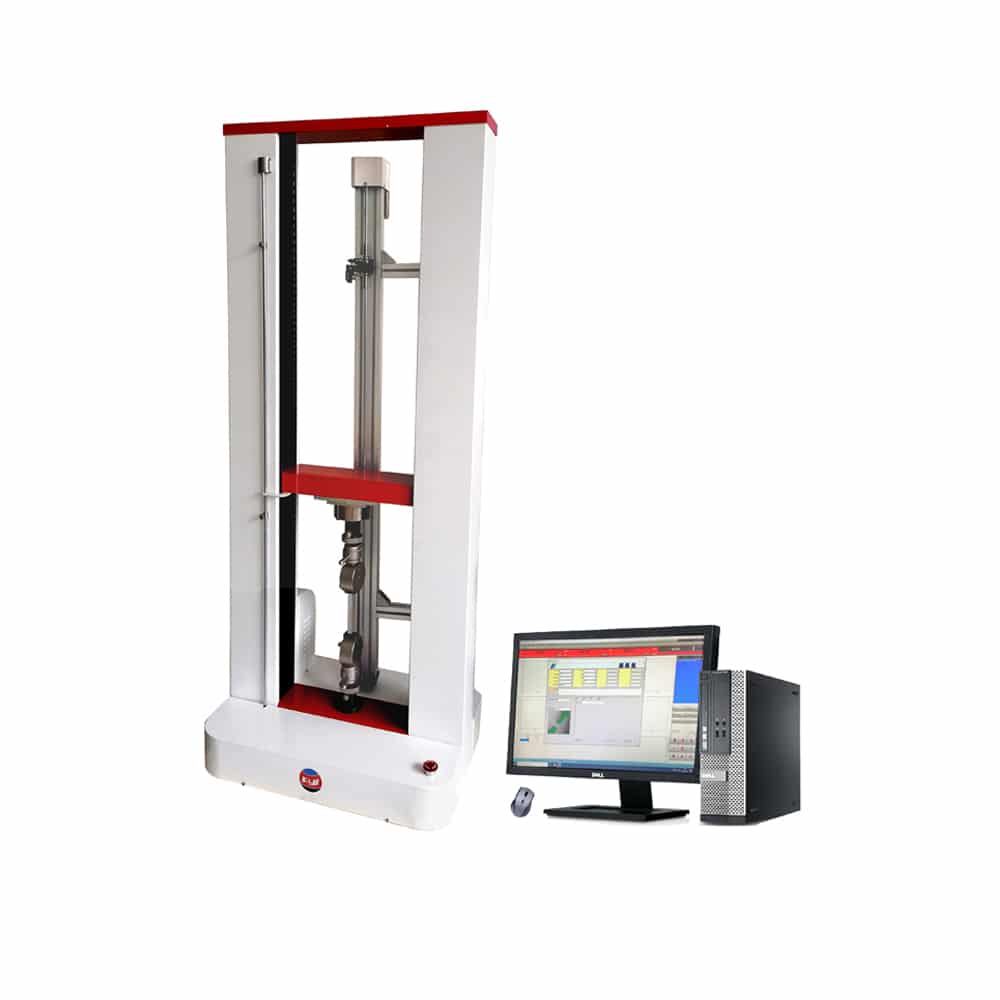

Definition and overview of universal testing machine

The universal testing machine is also called a tensile testing machine. It is an instrument used to conduct static load, tensile, compression, tearing, peeling and other mechanical property tests on various materials. It is suitable for testing various physical and mechanical properties of plastic sheets, pipes, special profiles, plastic films and rubber, wires and cables, waterproof membranes, metal wires and other materials.

Its use industries include: scientific research institutes, commodity inspection and arbitration institutions, colleges and universities, as well as rubber, tires, plastics, wires and cables, shoemaking, leather, textiles, packaging, building materials, petrochemicals, aviation and other industries, for material development and physical property testing , teaching research, quality control, incoming material inspection, random inspection of production lines and other indispensable testing equipment. As an important part of the instrument, the universal testing machine fixture is an important part of the instrument. Different materials require different fixtures. It is also the key to whether the test can be carried out smoothly and the test results. An important factor in accuracy.

Things to note when purchasing a universal testing machine

Test material tensile range

The difference in the pulling force range determines the difference in the sensors used, which also determines the structure of the universal testing machine, but this has little impact on the price (except for the door type). For general flexible packaging manufacturers, a pulling force range of 100 Newtons is sufficient. Therefore, it was decided to use the single-arm type.

The corresponding structure to the single-arm type is the portal structure, which is suitable for relatively large pulling forces, such as one ton or more. Therefore, flexible packaging manufacturers basically do not need it.

Test trip

According to the material properties and requirements that need to be tested, the general stroke is 600-800mm. If the material elongation exceeds 1000%, you can choose the stroke 1000 or 1200mm.

Standard configuration

There are three basic configurations of intelligence: host, microcomputer, and printer. If the microcomputer is powerful, it can print directly. In addition, it can also be equipped with an ordinary computer. With a computer, you can perform complex data analysis, such as data editing, partial enlargement, adjustable report formats, and group-style statistical analysis. If it is equipped with a computer, the manufacturer should add the corresponding control system.

Output results

The test result output results can be set arbitrarily: 8 items: maximum force value, elongation, tensile strength, constant force elongation, constant elongation force value, yield strength, elastic modulus, and maximum test force. This can be said to be the most comprehensive result output by microcomputer operation. Products from some manufacturers can generally output these 8 items.

Experimental projects that can be done

The universal testing machine is multi-purpose, that is, on the basis of being equipped with different fixtures, it can perform tensile, compression, bending, tearing, shearing, 180-degree peeling, and 90-degree peeling tests. In addition to the above items, there are some high-end universal testing machines on the market that can also test the friction coefficient due to their high sensor accuracy (some reaching one part in 250,000).

Main configuration of product machinery

There are screw transmission and rack transmission. The former is expensive and used for high precision and high test repeatability; the latter is cheap and used for low precision and low test repeatability.

The screw plays a decisive role in the precision measurement of tension. Generally, there are ball screws, trapezoidal screws, and ordinary screws. Among them, the ball screw has the highest accuracy, but its performance requires the operation of a computer servo system, and the entire set is relatively expensive.

The main cost of sensors lies in their lifespan. Photoelectric induction is one of the more advanced technologies and can generally be used more than 100,000 times.

Test speed

Some of the equipment on the market are at 10~500 mm/min, and some are at 0.001~500mm/min. The former generally uses ordinary speed control systems, which are lower cost and roughness affects accuracy; the latter uses servo systems, which are expensive and have high accuracy.

Measurement accuracy

Accuracy issues include force measurement accuracy, speed accuracy, deformation accuracy, and displacement accuracy. These accuracy values can be up to plus or minus 0.5. But for general manufacturers, reaching 1% accuracy is enough.

Applicable scenarios for different universal testing machines

Electronic universal testing machine

Widely used in various metals, non-metals, composite materials, medicine, food, wood, copper, aluminum, plastic profiles, wires and cables, paper, film, rubber, textile, aerospace and other industries to test tensile performance indicators , and at the same time, various test data processing software and test aids can be customized according to domestic and international standards provided by users. Digital display electronic universal testing machine is suitable for users who only want force value, tensile strength, compressive strength and other related data. If you need to obtain more complex parameters, a microcomputer-controlled electronic universal testing machine is your better choice. In terms of cost performance, electronic universal testing machines below 30T have more advantages.

Hydraulic universal testing machine

Mainly used for tensile, compression, bending and other mechanical property tests of metal, non-metal materials and parts, components and components. The hydraulic universal testing machine is an ideal testing equipment for industrial and mining enterprises, construction and building materials, quality inspection centers, water conservancy and hydropower, bridge engineering, scientific research institutes, and mechanics laboratories of universities and colleges. The manually controlled hydraulic universal testing machine is cheap and suitable for finished product inspection and single material index testing in industrial and mining enterprises. The electro-hydraulic servo universal material testing machine is suitable for steel and building materials testing laboratories with higher requirements. Electro-hydraulic servo universal material testing machines above 30T have more price advantages than electronic universal testing machines.

Universal Testing Machine

UTM-1422 Universal testing machine is designed for a wide range of uses, such as tensile elastic modulus, flexural elastic modulus, compression modulus, yield strength, tensile strength, breaking strength, elongation, compressive stress, compressive strain, shear, peel, tear , puncture testing of thermosets and thermoplastics. Suitable for engineering plastics, reinforced plastics, modified plastics, plastic profiles, plastic pipes, sheets, films, etc.

Leave a Reply

You must be logged in to post a comment.

This article left me wanting more; it was so well-written and informative that I found myself craving additional content on the same topic.

It’s refreshing to see an article that tackles such a complex issue with clarity and objectivity.

If you’re looking for a well-written and meticulously researched article, look no further; this is it.

It’s rare to find an article that not only informs but also inspires, but this one does just that.