Water Repellency Test – An Overview

People have demands for water repellency and water-conducting fabrics. The water conductivity and comfort of the fabric can be seen from the wettability of the fiber surface; the waterproof performance of the fabric can be enhanced by waterproof treatment or coating. Different methods are used to test the water permeability of the fabric. The different parameters obtained are all to characterize the water permeability of the fabric.

Contents

Water repellency test method

Tests on the water repellency of fabrics after waterproofing and breathable finishing can be divided into three categories.

Hydrostatic pressure method

The first type is the hydrostatic pressure test. The hydrostatic pressure method refers to the water penetration ability of the fabric under a certain water pressure. It is suitable for all types of fabrics, including those fabrics with waterproof finishing.

The waterproofness of fabrics is related to the water resistance of fibers, yarns and fabric structures. The measured results are different from water spray and rain on the fabric surface. The hydrostatic pressure method is used to measure the water repellency of fabrics. There are static pressure method and dynamic pressure method.

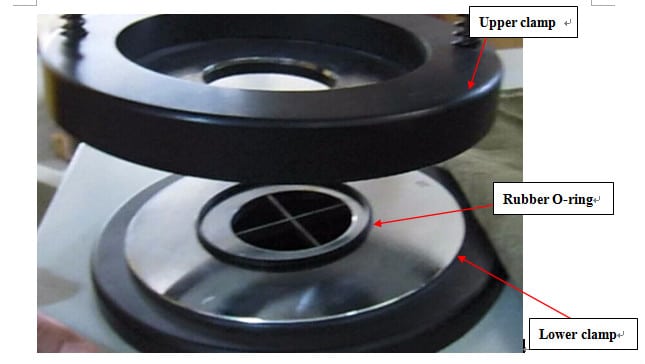

The static pressure method applies hydrostatic pressure to one side of the fabric, and measures the water output under this hydrostatic pressure, the water dripping time, and the hydrostatic pressure value at a certain water output. The hydrostatic pressure value can be the height of the water column or the pressure. In the actual measurement, the water permeability per unit area and unit time (mL/cm2·h) was measured. For waterproof fabrics, measure the time it takes for water droplets to appear on the other side of the sample, or observe the number of water droplets appearing on the other side after a certain period of time.

The dynamic pressure method applies a constant-speed increasing water pressure P on one side of the sample until the other side is penetrated by water and shows a certain number of water droplets. The imposed water pressure P has the same principle as the static pressure method, except that P is a variable. This method is more suitable for coated fabrics or fabrics with a tight structure, and uses hydrostatic pressure to reflect the water-blocking properties of the fabric. Fabrics with high hydrostatic pressure have strong water-repellent properties, while fabrics with low hydrostatic pressure have weak water-repellent properties. Water-conducting fabric has strong moisture absorption capacity and gets wet when exposed to water. It has no water repellency and does not generate hydrostatic pressure.

Spray method

The second category is the spray test. The spray method evaluates the water repellency of the fabric by continuously spraying or dripping water onto the sample, observing the water stain characteristics on the surface of the sample after a certain period of time, and comparing it with samples of various degrees of wetting. The spray method simulates how wet the clothes will be when they are exposed to drizzle. This method is applicable to all waterproof-treated fabrics and untreated fabrics. The measured waterproof results have a great relationship with the treatment of fibers, yarns, fabrics, and fabric structure.

Wicking

The third category is the wicking method, which is currently the most commonly used and simplest method to directly test the water absorption of fabrics. The test sample is usually cut into a long strip. One end of the test sample is suspended on an iron stand, and the other end is in contact with the water (or immersed in water to a certain height). After immersing for a certain period of time (f), the water climbs through the capillaries and fiber pores of the fabric are measured. height(h). Fabrics with good water conductivity have strong water absorption, fast water absorption speed (i.e., wicking speed), and high climbing height per unit time, that is, high water conductivity. If during the test, due to the relationship between fabric structure, fiber, yarn and color, the climbing process of water is not very obvious and cannot be well observed by the naked eye, you can add a little colorant to the water at this time.

Factors affecting water repellency of fabrics

The water permeability of a fabric is the ability of liquid water to penetrate from one side of the fabric to the other. Generally speaking, there are three main factors for the water repellency and water permeability of fabrics:

Fiber surface wettability

When the contact angle of the fiber θ<90°, the fiber aggregate material is a water-conducting material, and the tight structure will only lead to more capillary pores to wick water. When the fiber θ>90°, the fiber has water-repellent characteristics. When the fabric structure is tighter (that is, the pores are smaller), the water-repellent effect is better. Therefore, the water repellency or water permeability of a fabric can only be better discussed when the contact angle of the fibers is known.

Fabric coating

Coating the surface of a fabric with a continuous film layer that is impermeable and insoluble in water reduces the water permeability of the fabric and makes the fabric airtight. It’s not very suitable for clothing, but can be used for things like tarpaulins or ponchos. If a water-blocking, microporous coating film is used, a coated fabric with excellent water repellency, water permeability and air permeability can be formed.

Environment

Water-repellent fabrics or coated fabrics are mostly made of non-hygroscopic fibers or coated materials, so changes in relative humidity will not affect their waterproof properties. Water-conducting fabrics are mostly hygroscopic fiber materials. As the relative humidity increases, the moisture absorption of the fiber increases, the fiber expands and the capillary action increases, so the water conductivity of the fabric increases. Temperature has the same effect as humidity. Therefore, the environment has a great impact on water-conductive fabrics.

Water repellency tester

It uses a wiper mechanism to secure the test sample on a test cup. Raindrops fall from a height of 1.5m. By measuring the amount of water in the cup and the moisture content of the test cloth surface, the amount of water flowing through the test sample and the water repellent qualities of the fabric were evaluated. The tester is made up of four test cups with the same cross-section area (with wiper), a sprinkler, and a rainfall controller. To remove extra moisture from the cloth surface, an optional centrifugal dehydrator is offered.

Comments are closed.

Can’t emphasize enough how much I enjoyed reading this article; it truly expanded my horizons.

Lot of articles on this topic tend to be dry and academic, but this one manages to be both informative and engaging.

Know what sets this blog apart? It tackles trending topics with a fresh and unique perspective.

To the author’s in-depth research and thoughtful perspectives, this blog offers a wealth of valuable information.