Moisture Regain in Textile

The moisture regain of textile materials when they reach equilibrium under standard atmosphere is called standard moisture regain. The actual moisture regain of each fiber and its products varies with temperature and humidity conditions. In order to compare the moisture absorption capacity of various textile materials, the moisture regain (standard moisture regain) measured after a specified period of time (equilibration) under uniform standard atmospheric conditions is compared.

Contents

Calculation formula

Moisture regain is the difference between the wet weight and dry weight of the sample as a percentage of the dry weight. Suppose the dry weight of the sample is G0 and the wet weight of the sample is G, then the moisture regain W is

W=(G-G0) / G0 × 100%

Factors affecting moisture regain rate

Internal factors

- The role of hydrophilic groups: In fiber molecules, the number of hydrophilic groups and the strength of hydrophilicity can affect its hygroscopic performance. The more hydrophilic groups there are, the stronger the hydrophilicity and the better the hygroscopicity; fibers with low macromolecular polymerization degree will have stronger hygroscopicity if the macromolecular end groups are hydrophilic groups.

- Crystallinity of fiber: The lower the crystallinity, the stronger the moisture absorption capacity.

- Fiber specific surface area and voids: The larger the fiber specific surface area, the stronger the surface adsorption capacity, and the better the moisture absorption capacity; the more pores in the fiber, the stronger the moisture absorption capacity.

- Accompanying organisms and impurities: Different organisms and impurities have different effects. The cotton wax in cotton fiber and the oil in wool fiber weaken the moisture absorption capacity; the pectin in hemp fiber and the sericin in silk enhance the moisture absorption capacity.

External factors

- Relative humidity: Under certain temperature conditions, the greater the relative humidity, the better the hygroscopicity of the fiber.

- Temperature effect: In general, as the temperature of the air and fiber materials increases, the equilibrium moisture regain of the fiber will decrease.

- Air flow rate: When the air flow rate is fast, the equilibrium moisture regain of the fiber will decrease.

The impact of moisture regain on textiles

Effect on weight

Changes in moisture regain will of course cause changes in the weight of the textile material. What needs to be emphasized here is that in trade, the public weight is used as the basis for payment. Otherwise, either the buyer will suffer a loss (the material is too moist) or the seller will suffer a loss (the material is too dry), and the fairness of trade will be lost. This is also one of the main causes of trade disputes. . In production, the weight per unit length is controlled (quantitative control), and the weight of the fiber material increases in proportion to the amount of absorbed moisture.

Effect on length and cross-sectional area

The increase in moisture regain will cause the fiber volume to expand, and the transverse expansion is much greater than the longitudinal expansion. Reason: The macromolecules are arranged along the axial direction. After moisture absorption, the distance between the molecules increases, but the length of the macromolecules does not increase.

The hygroscopic expansion of fibers not only causes the fibers to become thicker and harder, but is also one of the causes of shrinkage (shrinkage) of the fabric. When water enters the fabric, the fibers absorb moisture and expand, making the yarn diameter thicker. The curvature of the yarns in the fabric increases and they are squeezed together. The fabric requires longer yarns in the warp or weft direction than the moisture absorption. The result is that the fabric shrinks. However, the hygroscopic expansion of fibers also has a beneficial side. For example, hoses and raincoats can use their fibers to absorb moisture and thicken when exposed to water, making the fabric tighter and making it more difficult for water to pass through. Swelling is also an important factor in processes such as creping, drying and dyeing of fabrics.

Effect on density

The density of the fiber first increases and then decreases as the moisture regain increases.

Effect on mechanical properties

For most fibers, their strength decreases with the increase in moisture regain, a few fibers remain almost unchanged, and the strength of individual fibers (cotton, linen) increases. The elongation at break of most fibers increases with the increase in moisture regain, while a few fibers remain almost unchanged. This is mainly due to the fact that after water molecules enter, the cross-links between macromolecules are broken down, the intermolecular force is reduced, and the macromolecules are easy to slip, so the strength is reduced.

As the moisture regain increases, the fibers become soft and easy to deform, the modulus decreases, and they are easy to tangle, while denser fabrics become stiff due to the support of the fibers; the friction factor on the fiber surface changes as the moisture regain increases. big.

Effect on thermal properties

As the moisture regain of textile materials increases, their thermal insulation properties gradually decrease, the cold feeling increases, the ignition temperature increases, the glass transition temperature decreases, the thermal shrinkage rate increases, and the resistance to melt holes improves. Changes in moisture regain have a great impact on the thermal properties of materials.

Effect on electrical properties

Textile materials are insulating materials, but their insulation properties will decrease as the moisture regain rate increases, the dielectric loss increases, and the electrostatic phenomenon will decrease.

Effect on optical properties

As the moisture regain increases, the optical refractive index of the fiber decreases. The absorption of light will increase, the color will darken, and photodegradation and aging will increase.

Test Methods

Direct measurement method

The direct test method is to first weigh the wet weight of the textile fiber material, then remove the moisture in the textile fiber material, weigh the dry weight, and calculate the moisture regain of the textile fiber material according to the formula defining moisture regain.

According to different methods of removing moisture from textile fiber materials, it can be divided into oven drying method, infrared drying method, vacuum drying method, high-frequency heating drying method, hygroscopic agent drying method, etc.

Indirect determination method

Using the principle that the amount of water in textile materials is closely related to certain properties, the moisture content or moisture regain can be inferred by testing these properties.

This type of method tests quickly and does not damage the sample, but there are many influencing factors, which affects the stability and accuracy of the test results to a certain extent. Some of these methods do not contact the sample and can be used for continuous testing in production, so they show great advantages in automatic moisture monitoring.

According to different testing working principles, there are testing methods such as resistance moisture measurement method, capacitive moisture measurement method, microwave moisture measurement method and infrared spectrum moisture measurement method. At present, the most commonly used method is the resistance moisture measurement method, which uses fibers to have different resistance values under different moisture regains (or moisture contents).

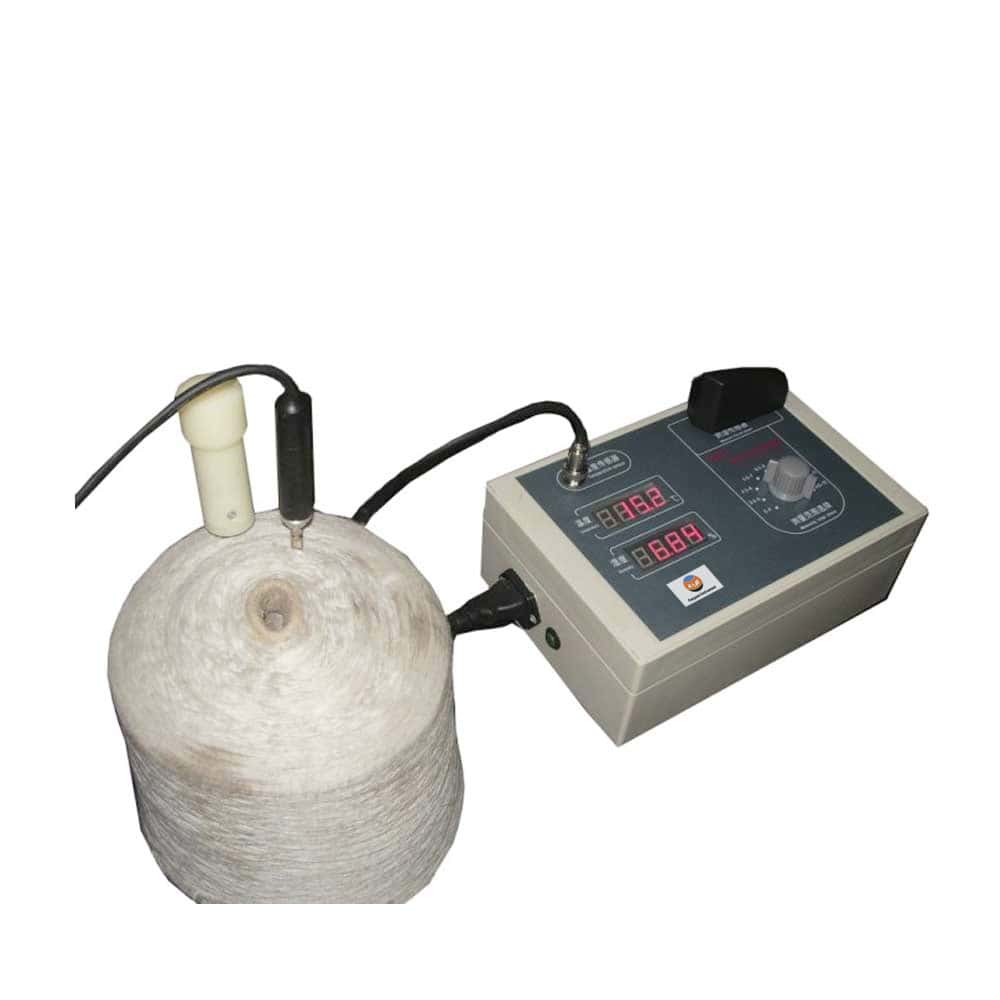

The digital moisture meter, which combines temperature and moisture testing capabilities, is extensively used in the moisture testing of pure cotton bobbin yarn, mixed bobbin yarn, and other chemical yarn.

This meter was created in accordance with the electric properties of fibers; the electric resistance of the sample should be in the range of 3.8×104Ω~2×1012Ω.

Moisture regain represents moisture absorption ability; the greater the moisture regain, the lower the electric resistance. By applying a voltage between fibers and measuring the resultant current, electric resistance values may be calculated.

Most articles fall short, but not this one – it struck the perfect balance between depth and readability.

I appreciate the author’s dedication to providing in-depth analysis and relevant examples, making this article a valuable resource for readers seeking a deeper understanding.

The way the author presents their arguments is both compelling and convincing, leaving no room for doubt.

I have read countless articles on this topic, but this one stands out as the most comprehensive and well-researched.

More than just informative, this blog is a source of inspiration and intellectual stimulation.