Twist Test Methods and Influencing Factors

Twist test is an important part of yarn inspection. It is related to the strength, elongation, appearance, style, etc. of yarns and fabrics. Different yarns have different structural characteristics, and their twist testing methods are also different.

Contents

Basic concept

To understand twist testing, you must first understand what twisting is. Twisting is a necessary condition for yarn formation. Short fibers can be made into yarns with certain physical and mechanical properties through twisting; filaments often need to be twisted in order to increase the tightness between single filaments, facilitate processing, and improve fabric properties.

Number of twists

Twisting is to cause two cross-sections of parallel straight fiber slivers to rotate relative to each other. The number of relative rotations of the two cross-sections is called the number of twists.

Twist

Twist refers to the number of twists per unit length of yarn.

Twist coefficient

In actual production, the twist coefficient is often used to express the degree of twist of the yarn. The twist coefficient is a physical quantity that is directly related to the twist angle of the fibers on the surface of the yarn. When the volume weight of the yarn is constant, the twist coefficient can represent the degree of twisting of yarns of different thicknesses.

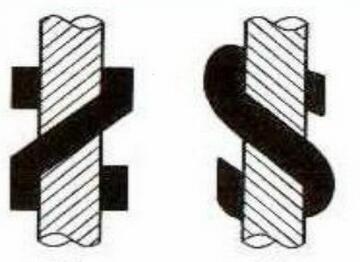

Twist direction

According to the direction in which the fibers on the surface of the yarn are tilted, the twist directions of the yarn include Z twist and S twist. For example, a double-stranded yarn is ZS twisted, which is composed of two Z-twist single yarns plied in the S twist direction.

Z twist: After twisting, the tilt direction is from bottom to top and from left to right, which is called Z twist.

S twist: After twisting, the tilt direction is from bottom to top and from right to left, which is called S twist.

Twist shrinkage

Yarn twist shrinkage refers to the length of yarn shortened or extended by twisting, expressed by twist shrinkage.

Classification of twist test methods

There are three main methods for measuring twist: direct untwisting method, one untwisting and twisting method, and three untwisting and twisting methods.

The direct untwisting method is suitable for measuring the twist of strands, the one-time untwisting and twisting method is suitable for measuring the twist of ordinary single yarns, and the three-time untwisting and twisting method is suitable for air-flow yarns.

Twist test principle

Direct untwisting method

Under a certain tension, clamp the two ends of the yarn of known length, fix one end, and rotate the other end around the axis in the untwisting direction. Until the single yarn or individual yarns in the strands or the single fibers in the multifilament are completely parallel. The number of twists receded is the number of twists within the length of the yarn sample.

One-time untwisting and twisting method

Under a certain tension, clamp the two ends of the yarn of known length, fix one end, and rotate the other end around the axis in the untwisting direction. Measure the number of twists when returning to the original length after untwisting and reverse twisting. The number of twists is twice the number of twists within the length of the yarn sample.

Factors affecting twist test

Pretension

There are different regulations at home and the abroad for the pre-tensioning of the untwisting and twisting method.

Excessive pre-tension will cause the pointer to slowly return to zero during reverse twisting, thereby increasing the twist in reverse twisting and causing fiber slippage in advance in the slip method;

On the contrary, if the pre-tension is too small, the twist will be relatively reduced during reverse twisting, resulting in a low value during the untwisting and twisting method test.

In the slip method and the secondary untwisting and twisting method, since the error caused by this tension change is taken into account, the method of subtracting the errors of the two samples is adopted, so the influence of tension is small.

Allowable elongation value

After the yarn is untwisted, the sample elongates, and the allowable elongation value set by the elongation limit prevents the slippage of the yarn fibers during the untwisting process. Experiments show that in the untwisting and twisting method test, the greater the allowable elongation value, the greater the measured twist value. At the same time, if the elongation value is too large, fiber slippage at the weak loop of the yarn will obviously affect the accuracy of the experiment. The allowable elongation value is related to the twist coefficient. The greater the twist coefficient of the yarn, the larger the allowable elongation value can be; conversely, it should be smaller. Usually the twist coefficient of yarn changes within a small range, so the difference in allowable elongation values will not be too large.

Uneven yarn dryness

Uneven yarn dryness will affect the twist test. If there are defects such as neps and slubs in the yarn, reverse twisting will begin before the original twist on the yarn is fully detwisted during the untwisting process, which will increase the test error. If there are long uneven segments on the yarn, it will affect the accuracy of the applied tension and eventually cause additional testing errors.

To sum up, in the yarn twist test, if the data deviation is relatively large, the above three factors that affect the test can be used as a reference to find out the reasons. It is not ruled out that there are human factors that cause the data to be inaccurate. No matter what kind of test, the inspector must be careful to ensure the scientific accuracy of the data.

Yarn twist tester

To determine yarn twist in double or plied yarns for traditional or twist/re-twist technique manually, a twist tester is utilized. For S and Z twist yarns, the test length is adjustable up to 30 cm (12 inches).

Right yarn grip rotation can be done in either the clockwise or the counterclockwise way. It is capable of adding pre-tension and has a magnifier to verify the level of yarn parallelization.

On the dial, there are 10 broad scales, each of which incorporates 10 small scales. Each wide scale corresponds to one round of the clip rotating.

Calculate the twist of 1m yarn according to the following equation,

T=1000/L×n

Where, n— the number of the untwist

L—the length of the yarn (mm)

Leave a Reply

You must be logged in to post a comment.

Did I mention how thoroughly researched this article is? The author’s attention to detail is commendable.

Did you ever struggle to find reliable information? Look no further! This article provides a well-researched and comprehensive overview of the topic.

I found it easy to find the information I needed within this article, thanks to its clear structure and well-organized sections.