Yarn Tension Test Method and Yarn Tension Meter

Yarn tension is used to measure the tension of moving or static yarn, thin steel wire, and plastic wire, providing a reliable basis for improving material quality and product performance.

Contents

Yarn tension

Generally speaking, “yarn tension” can be understood as the degree of tension of the yarn after being subjected to external force.

In the spinning process, there are tensions in roving yarns and fine yarns. To elaborate further, for example, during the twisting and winding process: The tension of the yarn from the front roller to the yarn guide hook is called spinning tension; The tension of the yarn from the yarn guide hook to the traveler is called balloon tension; The yarn tension from the traveler to the bobbin is called winding tension, etc.

The weaving process also involves yarn tension, such as warp tension, weft tension, yarn winding tension, etc.

In textile engineering, yarn tension results from work. The objects that exert force and receive force vary depending on different conditions and situations.

Yarn tension is a process parameter involved in each weaving process.

Tension is not only related to yarn breakage, but also to the efficiency of the equipment. It is also related to weaving shrinkage and fabric quality.

Tension is not only related to the properties of fibers and yarns, but also to the configuration of other process parameters in the production process of each process.

Theory and production practice prove that end breakage is weakly related to the strength of the yarn itself, but closely related to the yarn tension. Therefore, yarn tension is of great significance to production, process configuration and product development.

Differences between yarn tension and yarn strength

There are some differences between the strength and tension of yarns, which are mainly reflected in their properties, influencing factors, purposes, functions and measurement methods.

Properties

Strength is a measure of the maximum tensile force that a yarn can withstand during stretching. It is directly related to the breaking strength of the fabric and is an important indicator of yarn quality. Tension is the amount of pulling force exerted on the yarn, which mainly affects the quality and uniformity of the fabric.

Influencing factors

Strength is affected by factors such as yarn quality, thickness, material, and fiber length; tension is affected by factors such as yarn density, fabric structure, and machine speed.

Purposes

Strength is a measure of yarn quality and applicability. It can be used to evaluate the yarn’s strength, abrasion resistance, breakage rate, etc. to select suitable yarns for specific textile production. Tension is to ensure fabric quality and uniformity. The key factor of stability can be controlled by controlling the tension of the loom to ensure the flatness, density, texture, etc. of the fabric to meet specific textile requirements.

Functions

Strength is directly related to the durability of the fabric, which is its ability to resist tensile failure. Tension has a great impact on the organization and appearance of the fabric. For example, excessive tension will cause uneven organization and appearance of the fabric.

Measurement methods

The main methods of measuring strength include direct method and indirect method. The direct method is to directly measure the strength of the yarn through a tensile test, and the indirect method is to obtain the strength by calculating other relevant physical quantities. The measurement of tension is usually done by measuring the tensile deformation of the yarn at a certain speed and a certain distance.

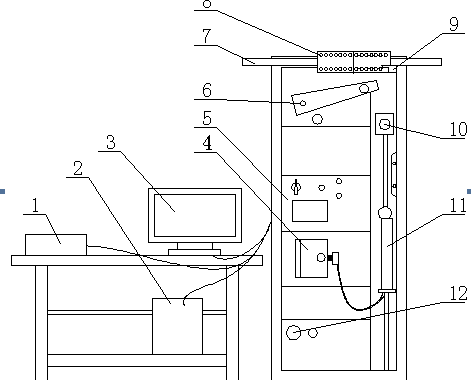

Yarn tension test method

According to the running status of the yarn and the immediacy of the detection results, it can be divided into static detection and dynamic detection. When statically detecting tension, the yarn being detected is in a static state or the detection result only displays one value. According to the display mode of tension value, mechanical type and electronic type can be distinguished. The mechanical type uses a pointer disk scale to display the tension value, and the electronic type uses an LCD screen to display the tension value. The dynamic detection is to measure the tension of the running yarn in real time and automatically record the dynamic changes of the tension.

From the perspective of usage, tension detection devices can also be divided into two types: handheld and fixed installation. According to the detection process, it is judged whether the detection element is in direct contact with the yarn and has an impact on the running state of the yarn.

From the detection of contact status, it can be divided into contact detection and non-contact detection. According to the difference in the working principle of the sensor, there are many types of contact detection and non-contact detection.

According to whether the detection element directly collects the tension signal from the yarn during the detection process, it can be roughly divided into indirect detection and direct detection.

Yarn tension meter

This digital yarn tension tester is designed to determine the tension of moving or static yarn, fine wire, plastic thread.

Yarn Tension Meters are utilized all over the world in a wide range of standard and specialized applications. Man-made fiber industries, cotton textile industries, knitting industries, optical fiber industries, wire industries, and so on are examples.

Three long and closely spaced slender shafts with precision guide rollers, as well as the end of the middle slender shaft, combine with the most recent microprocessor technology to make this instrument an excellent choice for tension measuring applications. If necessary, the operator can recalibrate the instrument.

Many international and retailer requirements are met by the Yarn Tension Meter.

Follows are features of tension meter for yarn:

- Aluminum profile with Aluminum outer casing.

- Three long and closely-spaced slender shafts with precision guide rollers, and the end of the middle slender shaft combine with the latest microprocessor technology.

- Employ a strain-gauge system for accurately perceive and record the tension change.

- Adjustable damping (10 steps) for easier readings when tension fluctuates,

- The large LCD display (4-digit) shows dynamic tension values calculated during the update, and can reach to accuracy of 0.1cN.

- The yarn tension meter automatically power off after about 3 minutes of non-operation.

Want to dive deeper into the topic? Look no further – this article provides all the information you need.

What impressed me the most about this article was the author’s ability to present the facts objectively, without bias or personal opinion.

From the moment I started reading this article, I was captivated by its engaging and thought-provoking content.

Most importantly, the sincerity and passion behind each word make this blog truly exceptional.

A must-read for both enthusiasts and experts alike, this blog caters to a diverse audience.